Weather can play a big factor in how much you enjoy your muscle car, and not just when the roads are wet or icy. For those living outside of temperate areas like California, big swings in temperature, humidity and barometric pressure can play havoc on your classic Mopar’s carburetor tune. Attempting to chase the ups and downs of the often erratic seasons will have you stockpiling coffee cans full of different sized jets, extra floats and just more parts than you bargained for, not to mention hours upon hours of jetting and tuning.

We learned this lesson first hand this winter with Mopar Connection‘s Project Brazen ’69 Dodge Charger. Balmy 55-degree weekdays alternated between bone-chilling sub-freezing weekends, and not driving our car simply wasn’t an option (especially when the roads were clear). We fought to find the Charger’s “sweet spot” to make our carburetor happy – even going so far as to install a wide-band O2 sensor in one of our headers. Tuning the carburetor was becoming such a distraction that other issues that needed to be addressed were taking a backseat.

Above: We brought Brazen back to Mike Petralia’s Hardcore Horsepower to perform the carburetor-to-FAST EZ-EFI 2.0 swap, as well as use his Dynocom Racing chassis dyno to perform the initial break-in and preliminary tune. A later wide-open-throttle (WOT) dyno run will be made once the FAST system has had enough time to learn what our big stroker 535ci Wedge likes.

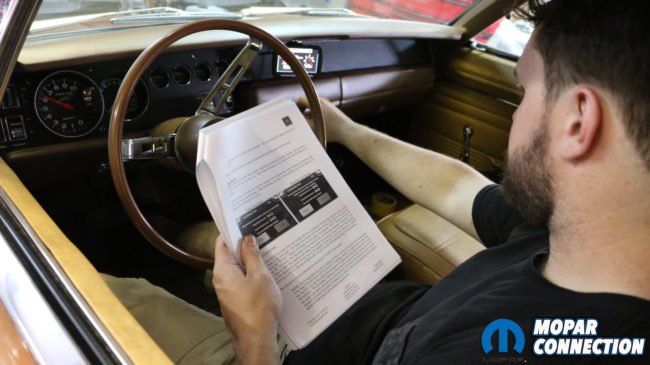

Above: The entirety of the FAST EZ-EFI 2.0 system – including the EFI throttle body, complete ignition system (including ECU, ignition box, coil and Race Billet distributor), inline fuel pump, fuel pressure regulator, fuel pressure sensor, mesh-wrapped wire loom, and digital hand-held tuner can be intimidating at first blush. FAST includes comprehensive instructions that guide you step-by-step to make the installation as painless as possible.

Above left: Mopar Connection Tech Editor Mike Wilkins begins the removal of the previous ignition system. Above center and right: Wilkins noted where exactly the rotator was aligned prior to removing it.

Needless to say, frustrations were already high when COMP Performance Group’s (CPG) Trent Goodwin joked, “Are you ready to step into the 21st century and go fuel injected?” Understandably, we were ready. Electronic fuel injection swaps have come a long way since the early 1980s, particularly as hardware was reduced in size allowing much of it to fit in a single throttle body package. And the advantages over carburetors are self-evident: consistent and precise fuel delivery, improved drivability, lowered emissions and increased fuel economy to name a few – and all things desperately lacking from our project car.

COMP’s Fuel Air Spark Technology (FAST) division was already becoming the go-to for electronic fuel injection swaps for multiple applications, and with the introduction of the self-tuning EZ-EFI 2.0 a couple of years ago, the decision was all but made. Unlike other carburetor-replacement throttle body EFI systems that max-out at 600-horsepower, the EZ-EFI 2.0 system can support anything from a stock 340 to a 1200-horsepower, high-compression blown Hemi engine.

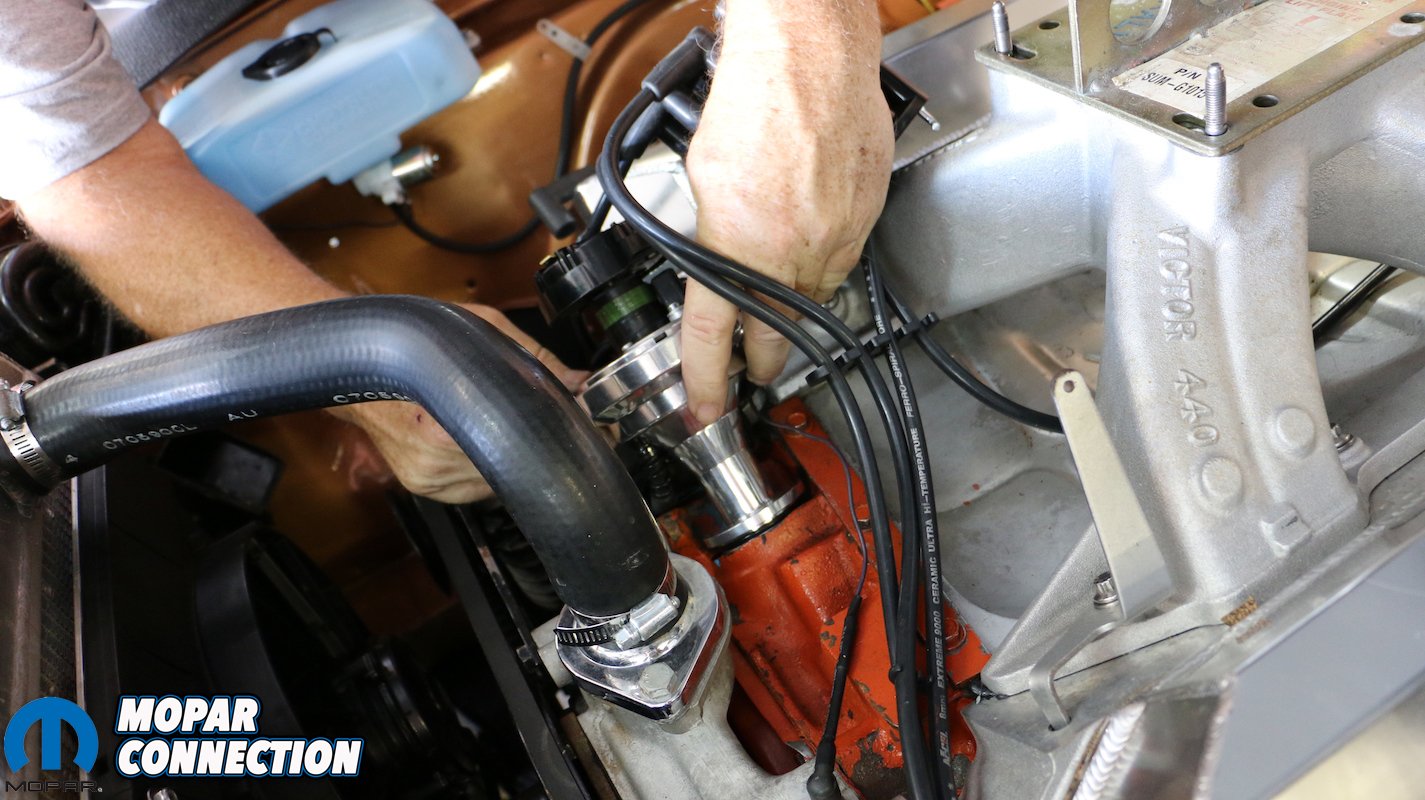

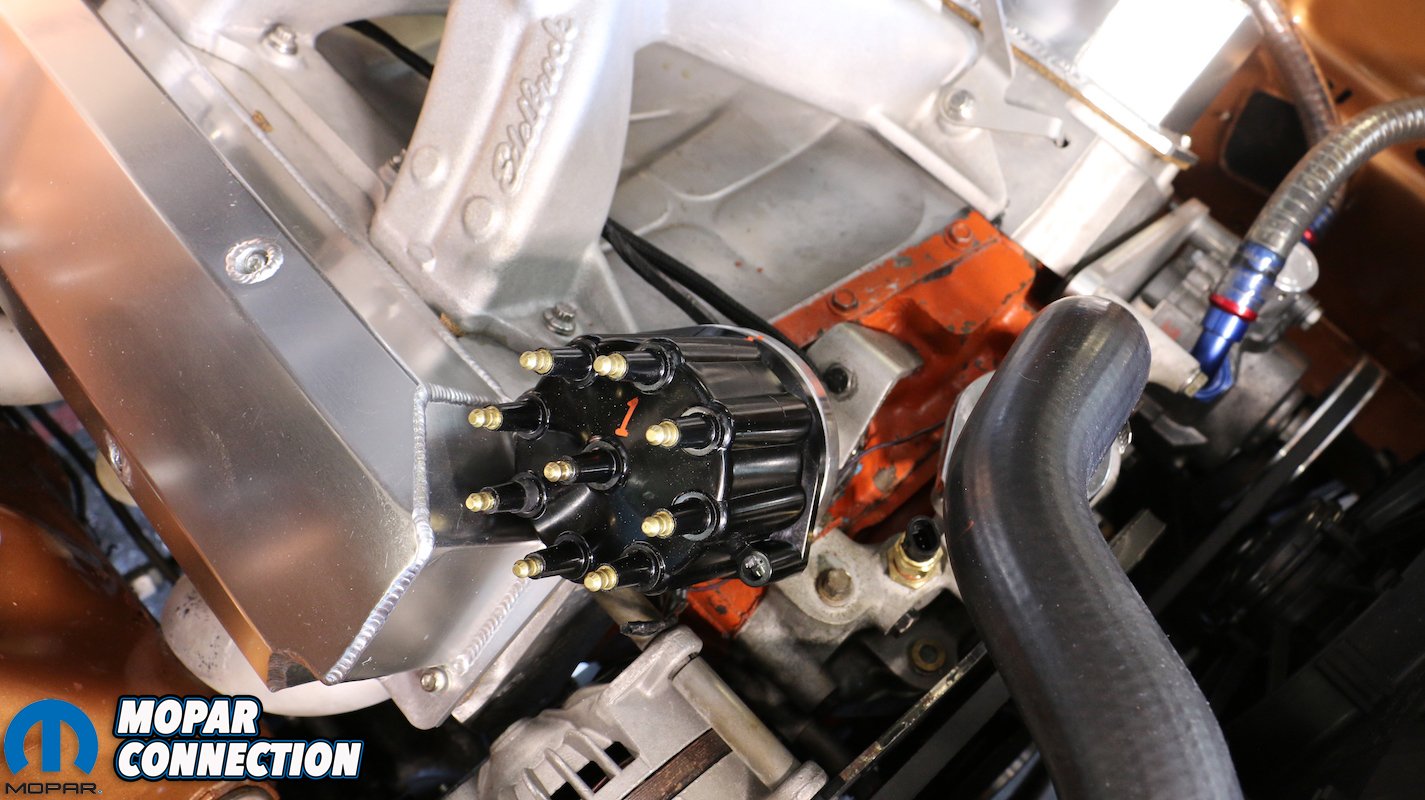

Above left: Wilkins’ wisely noted the differences between our outgoing Mallory billet distributor and our incoming FAST Race Billet distributor. Above center: If there ever was a lesson to be taught to hot rodders, it would be to never expect performance parts from two different aftermarket companies to fit together, ever. The new FAST distributor wouldn’t fit with our Edelbrock RPM Performer heads, requiring us to make some tough decisions. Above right: Because of the thick casting of the Edelbrock heads, we opted to mill as much extra aluminum off of the left-hand side cylinder head until the billet distributor fit comfortably into place.

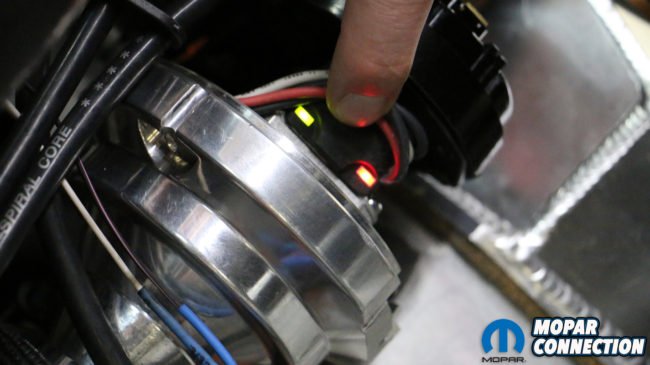

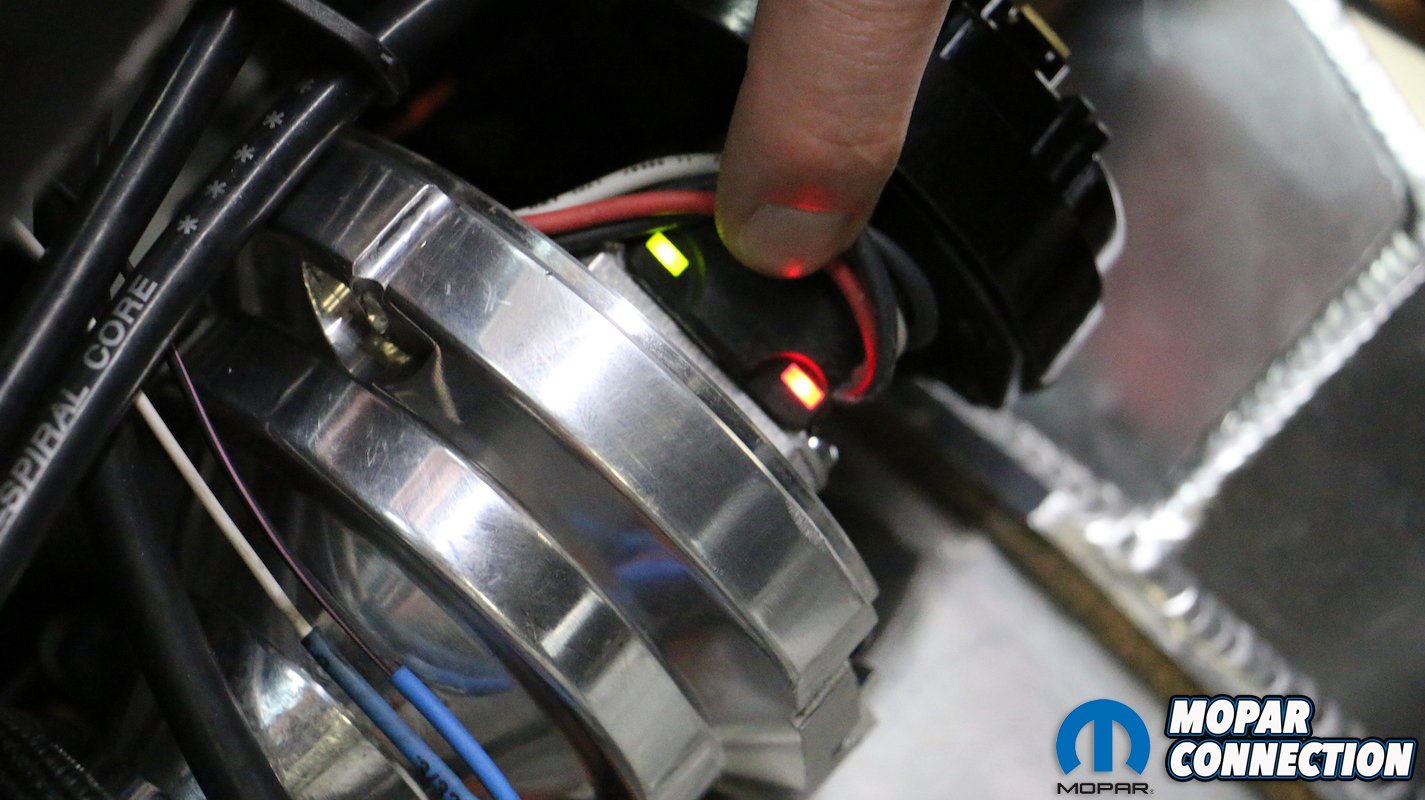

Above left: When the new rotor is properly aligned towards the number one cylinder, the distributor’s LED module will illuminate both a red and green light indicating the cam and crank signals, respectively. Above right: With both LEDs lit, we locked down the distributor and reinstalled the cap. The ECU will be able to advance or retard timing depending on load and the parameters programmed into the dash.

Above left: Hardcore Horsepower’s Morgan Olsen began fabricating an electronics panel that will mount to the inside of the firewall behind the glovebox. Above center: The panel houses both the ignition box and FAST ECU as well as much of the unused wire loom. Above right: To get the FAST ignition coil to replace our larger MSD Ignition coil we fabricated a small mounting plate so we didn’t have to drill more holes into our inner fender well.

This is in large part due to the EZ-EFI 2.0’s use of eight injectors instead of the typical four. The added injectors also make it the industry’s only fuel pulse dampening throttle body EFI; allowing the installer to run a return or returnless fuel system. Additionally, the EZ-EFI 2.0 can be programmed to run E85, another industry first. The system’s own proprietary ECU can operate with a traditional distributor or one of FAST’s own electronic Race Billet Distributors thanks to its electronic ignition control, which includes a nitrous timing retard, just in case we were planning to bottle-feed Brazen at some point.

The incorporation of the ignition timing elevates the EZ-EFI 2.0 from just a fuel injection swap to a total engine management system. To better explain how this came to be, Mopar Connection got the chance to talk with FAST’s Sales Manager, David Page who explained, “My interaction with dealers, installers, and end users showed me a need for a system like the original EZ-EFI, but with the ability to support more horsepower and the added benefit of ignition timing control.”

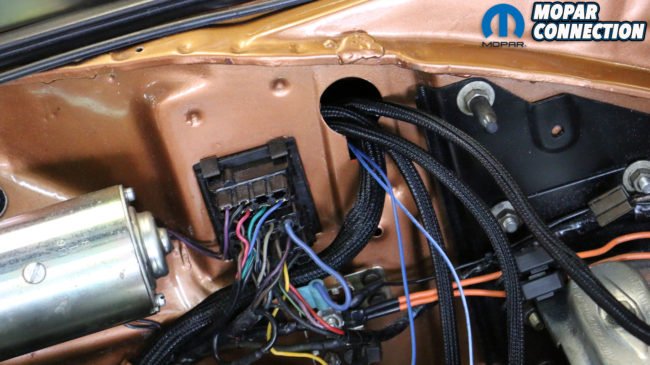

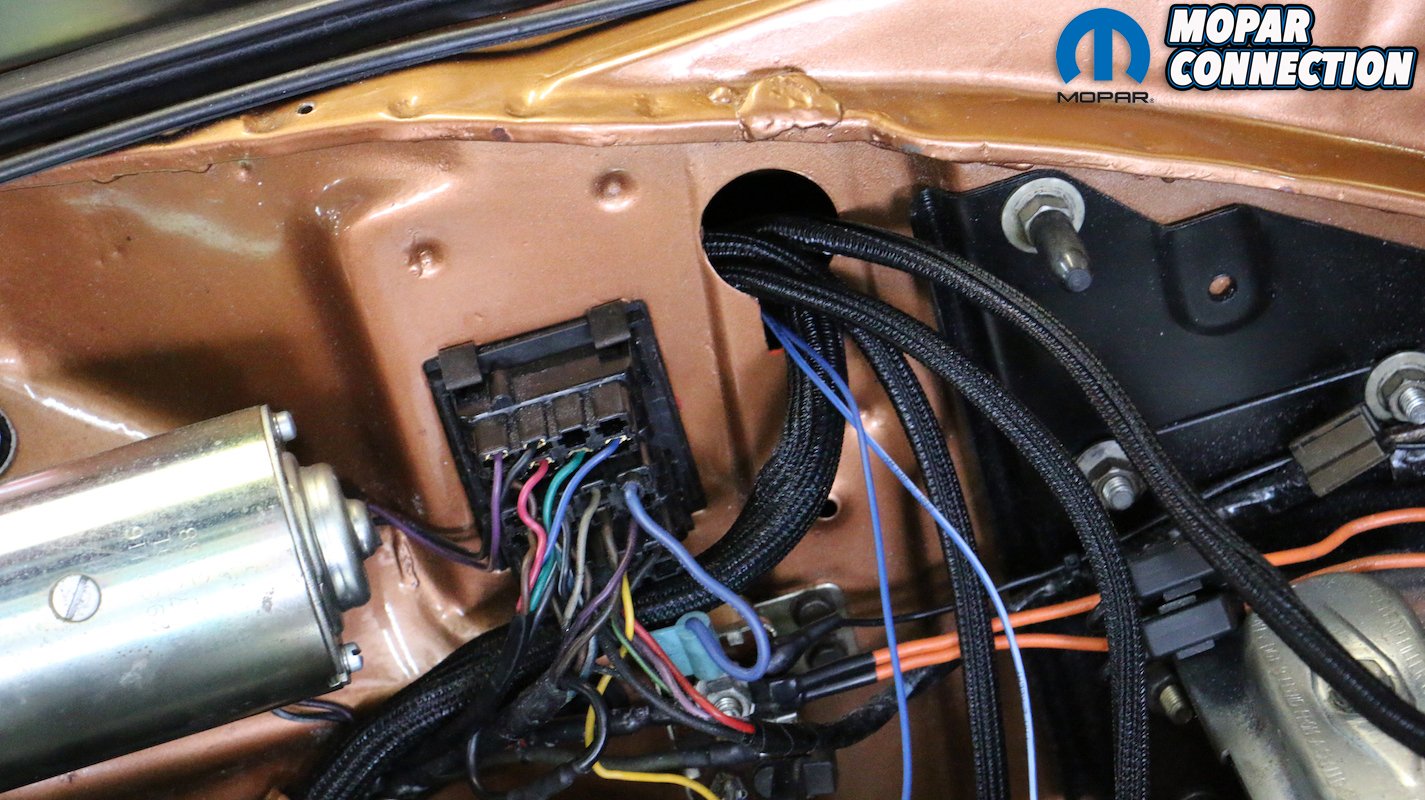

Above left: The FAST EZ-EFI 2.0 includes a massive wire loom with precision-fit plugs for nearly every imaginable application. Because of the simplicity of our project car, much of the loom wasn’t needed, so we removed the 2-inch diameter bulkhead grommet and fed what wires we needed through the unused firewall hole we had from the factory vacuum-operated headlight door system that we had plugged up. Above right: In addition to the loom running to the distributor, the throttle body and TPS sensor, we also utilized the system’s fan control feature, having Morgan wire it directly into our Be Cool radiator relays.

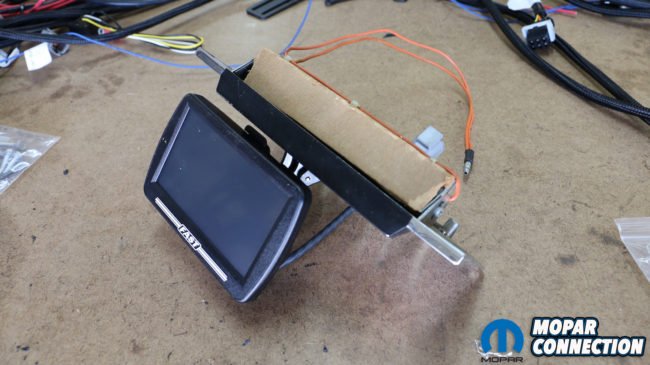

Above left: FAST emphasizes that the system’s main power and ground wires be directly connected to the battery, as the system operates on electrical signals that typically operate on a 0-5-volt scale. If not properly grounded, things can go real bad really fast. Equally, this also allows the battery to act like a giant voltage spike suppressor. What you’re seeing is Morgan feeding wires from behind the backseat into the trunk to our rear-mounted battery. Above right: Because Brazen no longer uses its air or heater, our control panel was there mainly for looks. Now its the base for our invertedly-mounted hand-held dash tuner.

Above: The EZ-EFI 2.0 is capable of running either with a return fuel line or with a returnless setup. A returnless system requires that the fuel pump be mounted in the tank, while a return system allows for the pump and filter to be mounted externally. Either way, we were going to need to drop the tank so we could plumb in a return line. We cleaned the tank and installed a bulkhead fitting for the return line.

Since we were pretty resistant to installing a system that required us to plug in a laptop to tune our car, the EZ-EFI 2.0’s self-learning software thankfully does all of the hard work for us. Page noted, “The most impressive feature of the EZ-EFI 2.0 is the ability to support a massive amount of horsepower and learn the fuel needs of the engine quickly.” The system’s ECU comes preloaded with a bank of base maps to safely get the engine fired up, idle and drive, but more importantly, as the engine runs and the car is driven, the ECU will continue to gather data and automatically begin to adjust and improve upon the baseline tune.

Of course, to begin, the tune will lean more on the safe side, operating conservatively to avoid hurting the engine. This means any wide open throttle dyno pulls were out of the question – at least for now. Installation of the EZ-EFI 2.0 system is made easier thanks to a complete high-quality wiring harness (wrapped in a mesh loom) and contains coordinated plugs that only can fit in its right receptacle. Because of the simplicity of our installation, much of the loom simply wasn’t needed – and that’s saying something considering the EZ-EFI 2.0 features the least connections in market. The kit also comes with a wide-band O2 sensor and bung if you don’t already have one.

Above: Although FAST provided us with enough high pressure fuel hose to route both the positive and return lines, we simply repurposed our factory steel fuel tubing as the return line, terminating it above the differential, where we plumbed on a short length of hose to our new bulkhead fitting.

Above: In routing our positive fuel line, we ran the high-pressure rubber fuel hose provided by FAST from our factory Chrysler in-tank pickup up and over the differential and down the subframes, running on the inside of our subframe connector until it reached the forward subframe. There the fuel lines ran up the firewall to the throttle body.

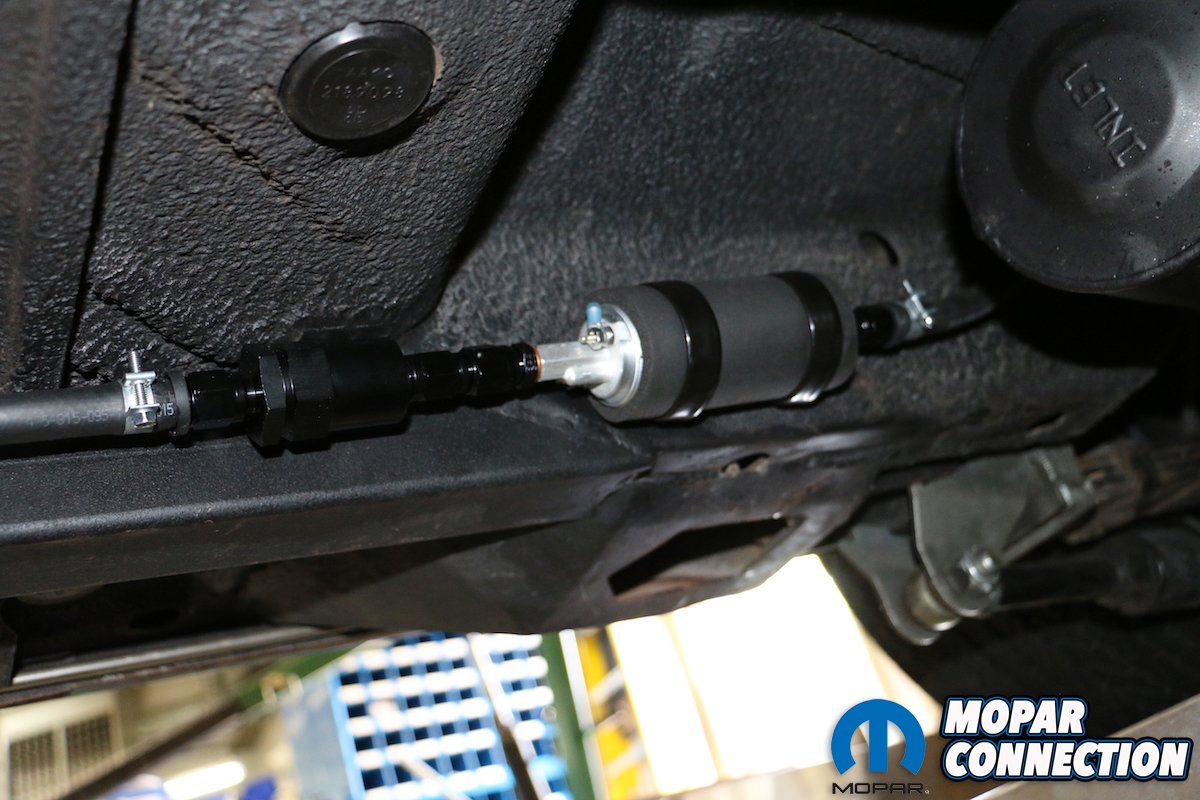

Above left: Note the position of the fuel pressure sensor, which is mounted on the positive line just behind the in-line fuel pump and filter. Above right: The fuel pump is plumbed directly into the filter before passing through the fuel pressure sensor, all inboard of the subframe and subframe connector. FAST requests that the pump be mounted below the lowest point of the tank and as close to it as possible.

Page touched on the ease of installation, stating, “The simplicity of the installation process, and how the throttle body not only looks like a carburetor, but accepts the same linkage and air cleaner as a carburetor, takes the intimidation out of switching to EFI, while retaining the traditional classic looks in the engine compartment.”

Apart from the throttle body, the system’s most impressive component is the modern full-color touchscreen hand-held tuner, which also doubles as sensor dash. Once the installation is complete, we used the hand-held tuner’s Setup Wizard to guide us through start-up and making preliminary adjustments to the fuel regulator, throttle-position sensor, idle-air control and ignition timing. From there, the computer will continue to monitor driving inputs and conditions and adjust the tune accordingly.

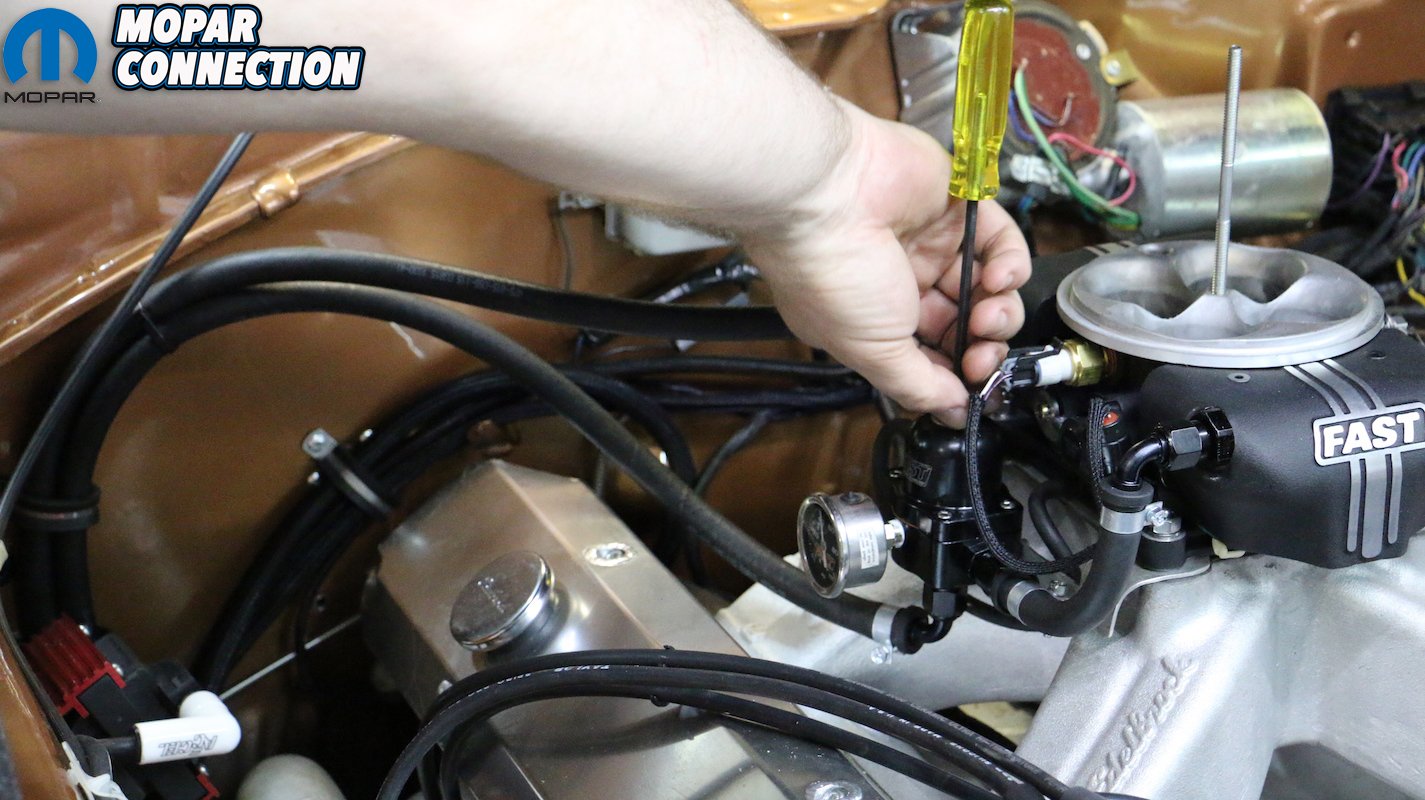

Above left: Because we were running a return line system, the positive fuel line runs from the pump, filter and sensor to the rear port of the throttle body. The return line flows from the forward port on the throttle body, to the regulator and back to the tank. Above right: Sanctioning body rules prevent the regulator from being mounted to the firewall, so Petralia fabricated this aluminum bracket mounting the regulator alongside the throttle body.

Far left: Morgan begins the Startup Wizard prompt. Center left: Pages within the prompt will ask basic questions like cubic inch displacement, number of cylinders, etc. Center right: Additional pages will ask for specifications of the system including what type of ignition system is being used, what kind of fuel and more. It’s incredibly easy to follow. Far right: The Startup Wizard will also ask for the desired air/fuel ratio (13.2-to-1 for our application), as well as timing advance and other tuning specifics.

Above: One final step prior to firing up the engine is that the Startup Wizard will confirm the fuel pressure level (it’s supposed to be 43 lbs.). Ours read a little low, so we needed to adjust accordingly. A vacuum line also runs between the throttle body and the regulator.

“The more time it has to learn, the better it’ll run,” Page counseled. “In fact, we often tell people to go drive their cars in traffic. The constant on again/off again of driving in bumper-to-bumper traffic is great for the ECU to learn.” If that is a little concerning, do not fear. In addition to controlling air/fuel ratios, fuel delivery rate and throttle position, the EZ-EFI 2.0 also can control at what temperature to engage your electric fans and for how long – all through the systems Advanced settings.

Once running, the touch-screen tuner can be toggled through different screens to show a variety of different dashboards, all of which provide live monitoring of the engine’s parameters (air/fuel ratio, fuel pressure, air intake temperature, coolant temperature, etc.). Whether its a hot and humid Louisiana afternoon, a chilly Michigan morning, or the middle of summer atop Pike’s Peak, the EZ-EFI 2.0 will not only fire up with no more than a twist of the ignition, but idle, drive and operate smoothly – and the freedom to drive your car any time or season of the year is worth the cost of admission alone.

Above: We were lucky to have FAST’s own David Page take a break from helping work with the EFI racing team in Bowling Green, KY, and come down and walk through us through the initial tuning process. Page showed us just how easy the hand-held dash makes changing, and improving, initial start-up, idle and driving parameters.

Above: With some pointers from Page, and double-checking our distributor clearancing, we were given the go-ahead to start the dyno and roll the Charger through the gears.

Above: While today was not the day to be making any big power pulls, we were very satisfied with how effortlessly the FAST EZ-EFI 2.0 fired up the Charger and brought it to idle. Even with temperatures swelling to well past 100 in the shop, the big Wedge rumbled better than it ever had before. While Petralia states that swapping from a carburetor to EFI shouldn’t produce any big horsepower gains (that is, if the carb is tuned properly), we can assure that throttle response and driveability have never been better. Ever. We’ll have a follow-up on the EFI’s progress soon enough with a true dyno pull once we’ve logged several more hours on the ECU.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by