There’s an old adage about hot rodding: you’re lucky if stock OE parts fit. If you’re making one change, expect it not to fit. If you’re making two changes, expect to have to cut it to fit. If you’re making three (or more), expect to start from scratch. In the case of Mike Wood’s very bizarre ’73 Plymouth ‘Cuda being built by Rod & Custom Machine, this street rod is requiring to be re-engineered from pretty much the ground-up.

In our previous installment (included below the line break), we outlined the initial plans to build hemi-headed small block LA motor stroked and bored to over 400ci, and force-fed by twin Turbonetics turbochargers, blowing in through dual throttle bodies. Rod & Custom’s Jeremy Goodstein smirks, “It’ll make over 1,000-horsepower on the ‘low’ setting.” Backed by a 6-speed overdrive automatic and fitted with a complete tubular suspension system, air conditioning, Holley electronic fuel injection and a whole lot of sheet metal from Classic Muscle Metal, this ‘Cuda is on its way to become a truly one-of-a-kind E-body.

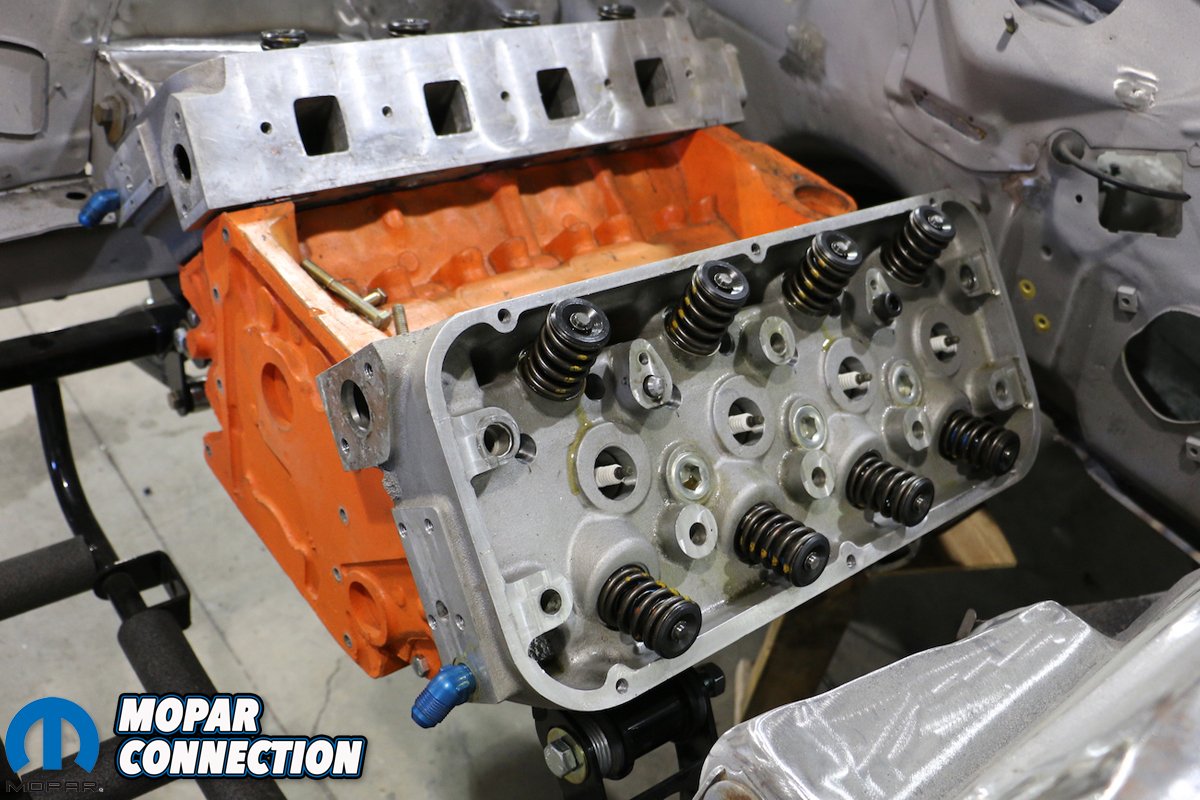

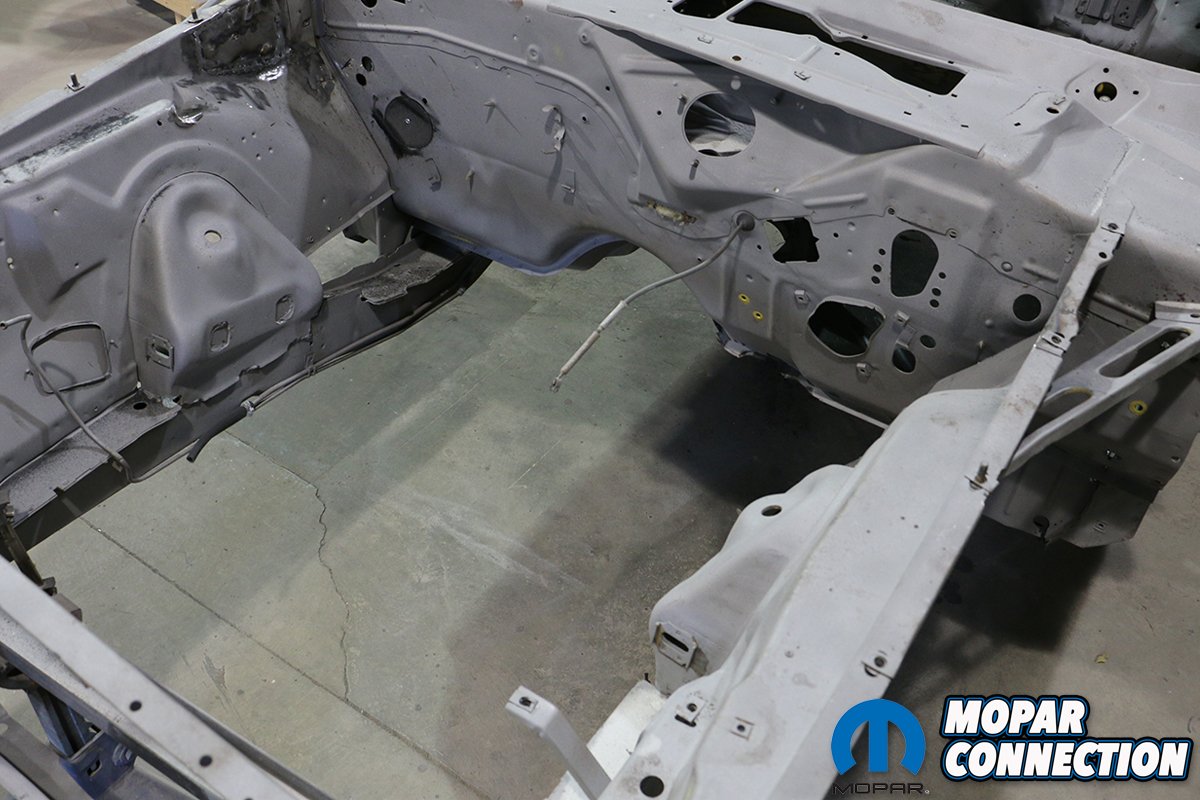

When we stopped in a couple of weeks ago, progress had been made since January but to the layman, it would appear very little. All of the rotted steel had been removed, with Goodstein and crew replacing the trunk pan, rear subframes, quarter patch on one side and a complete quarter on the other, a mini-tub kit, torque boxes and subframe connectors. “It’s going to take a lot to keep the car together with all of that power,” Goodstein explains. Equally, a plastic LA block had been dropped in for initial setup measurements.

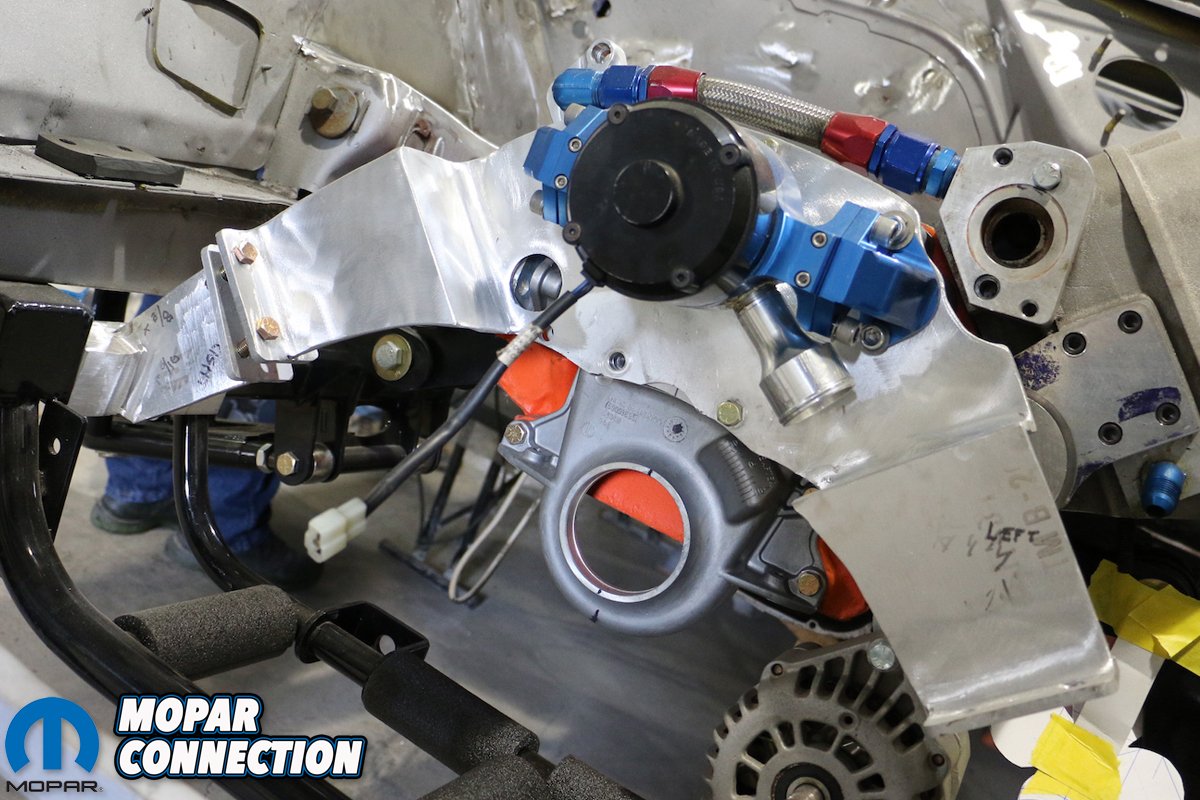

“It’ll be running a motor plate,” Goodstein continues. “We sectioned it so the engine can be taken out easily.” The plate is also acting as a unique accessory mount, as the extreme plumbing necessary for the twin turbos requires the conventional locations for the AC compressor and alternator to be relocated. This in turn, is requiring quite a bit of creative fabrication to make everything fit in the normally ample engine compartment. “Using an electric water pump allows two things,” Goodstein concluded. “First, it’s one less pulley to try to make work, and second, we can control the engine temperature a lot better through the Holley EFI.”

Last update: January 3, 2017

Yeah, that headline is quite a mouthful, huh? We really didn’t believe it when we heard it either, that is until we saw the project in person. With the coming of the New Year also heralds a whole new batch of amazing projects, and one that has definitely got our attention is this peculiar ’73 Plymouth ‘Cuda being built by Rod & Custom Machine out of Dickson, TN.

For those who might’ve heard of Rod & Custom before, they’re the masterminds behind the hemispherical (ie. “hemi”) cylinder head conversion for LA small blocks, as well as designing and machining their own line of 6.71 and 8.71 roots-style blowers, and complete Gen II valvetrain assemblies (among other things). Unbeknownst to us, they also dabble in building cars for customers.

One such customer is Mike Wood from Frankfort, KY. Mike was in line to purchase a Hellcat Challenger but was in the market for an automatic and wasn’t terribly interested in paying the ridiculous markups dealers were asking a few years ago. Unable to find one to his liking, to struck up a conversation with Jeremy and Mike Goodstein of Rod & Custom who presented this idea instead.

Jeremy explained to Mopar Connection, “We are doing all of the metal work right now; it should be done here in the next few weeks. With that we are cutting out the shock towers and smoothing the whole engine compartment, putting new quarters on the car, new trunk floor and driver’s side floor. Then we are going to start putting in the frame rail connectors and the roll cage and also start the engine build at the same time.”

Using their own hemi-conversion kit, a small block will be stroked and bored to over 400ci, fitted with twin Turbonetics hairdryers plumbed into twin throttle bodies (“We’re thinking about an intake like what’s on the Vipers,” Jeremy suggested). A 6-speed overdrive automatic is also planned. Replacing the factory leaf spring and torsion bar suspension will be a complete Gerst tubular suspension coil-over system, including a K-frame, upper and lower control arms and 4-link rear linkage.

Mopar Connection will be following this build every step of the way, so stay tuned for plenty of updates (including a full feature on the insane powerplant) until its full reveal in late Spring/early Summer. So, until that time, make sure to check out Rod & Custom Machine and their awesome hemi-ready performance parts and services HERE!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by