Vehicles can develop vibrations as tires, suspension, and drivetrain components age. Our 1967 Dodge Dart recently developed a minor, yet bothersome, vibration at about 45 mph while in high gear. The vibration did not occur at idle or when the Dart was not in motion, so it was related to the drivetrain, brakes, or tire/wheel assemblies.

Above Left: Our 1967 Dart had developed a minor vibration that we isolated to the driveline. Above Right: We finally isolated the problem to the transmission mount. Not being familiar with the Dart’s history before 2018, there was no way to ascertain the age of the component.

Upon further investigation, we noted that the vibration occurred while accelerating or cruising but could not be felt when coasting through the vibration speed area. The wheels and tires were recently inspected and re-balanced, which eliminated them. During several test drives, we applied the brakes (lightly and heavily), and during the deceleration, the vibration could not be felt as the speed dropped. So, we concluded the vibration concern must be in the drivetrain.

Above: YearOne had the part we needed to fix our Dart’s vibration concern. The mount fits many A- and B-body models from the muscle car era.

In September 2020, we wrote “Angling In On Driveline Inclination with YearOne and WFO Concepts,” where we installed an 8 3/4-inch rear end with 2.94:1 gears. We also fitted a used factory driveshaft that we had removed from our 1969 Dart decades ago. The driveshaft was spun balanced before its installation into our ’67 Dart. Could the problem be something we did, or did something that we did not replace fail?

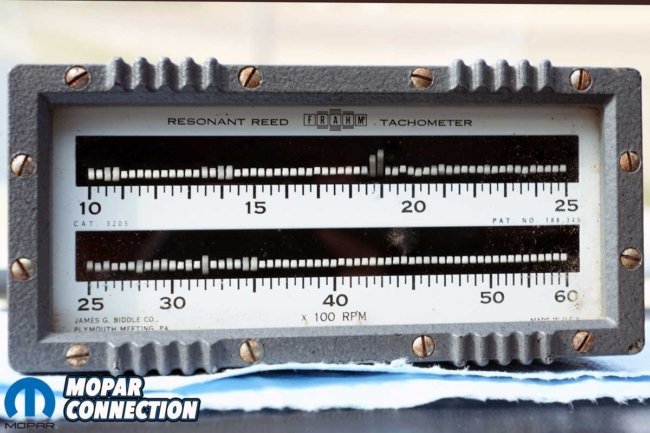

Above Left: To isolate the cause of the vibration, we used a Reed tachometer. While there are Electronic Vibration Analyzers (EVAs) and other vibration diagnostic tools, the Reed tach was a simple tool that operated without the need for power. Above Right: At 45 mph, our vibration showed up on the Reed tach at about 1850-1900 rpm. We ran the Dart above and below 45 mph, and the Reed tach did not pick up any substantial vibration, but at 45 mph, it consistently measured the vibration.

Our investigation led us to perform a thorough visual inspection and recheck the driveline angles. We used the same inclinometer from the 2020 story to verify that the driveshaft working angles had not changed. Our measurements showed the driveshaft angles were nearly identical to the day they were set. There was nothing apparent that would have caused the vibration concerns.

Above Left: We had to remove our driveshaft loop to reach the transmission mount. A bracket attached to a front seat mount was removed first. Above Center: The two innermost transmission cross member nuts were removed, and the loop was slipped away from the cross member. Above Right: After supporting the transmission tail shaft, we removed the nuts from the other two cross-member bolts. Three of the four bolts slipped out of the cross member without any difficulty.

Again, we drove the Dart, but this time while observing a Reed tachometer to measure the vibration. Reed tachometers measure speed-related vibrations by contact. The tachometer is the key to finding many speed (rpm) difficulties, especially checking speeds of totally enclosed rotating equipment—Reed tachs function on the well-known and time-tested standard of resonance.

Above Left: Two bolts hold the transmission to the mount. Both bolts were removed with hand tools. Above Center: We could not get one transmission cross-member bolt removed because the center console shifter linkage was in the way. The lower shifter shaft plate was removed. Above Right: The speedometer cable was also in the way, so we removed it.

The Reed tach was placed on the Dart’s dash, and we witnessed the reeds vibrating rapidly at approximately 1900 rpm (or 31 hertz (Hz)) when cruising at roughly 45 mph. Performing some simple math, we calculated the tire/wheel frequency. To determine the tire revolutions per second at five mph (the standard for the math calculations), we divided 45 mph (our vibrating speed) by five mph, which resulted in nine.

Above Left: With the shifter in 1st gear, the shaft and lever swung around just enough to clear the remaining cross-member bolt. Above Right: With the last bolt removed, the cross member slipped away from the chassis.

We looked up the Dart’s tire size, P185/75R14, on a tire revolution chart (included in the photos). That tire size rotates 1.16 times per second at five mph. We multiplied the five-mph value previously calculated (nine) to 1.16, which resulted in a reading of 10.44 Hz. Next, we multiplied 10.44 Hz times 2.94:1 (the rear gear), resulting in 30.69 Hz (or 1841 rpm). The mathematical calculations were almost identical to the 1900 rpm reading on our Reed Tachometer.

Above Left: One last fastener held the transmission mount to the cross member. It was easily removed with a ratchet and socket. Above Right: The transmission mount was pried from the cross member. It was rather loose, but the pry bar helped extract the mount.

The results pinpointed the driveshaft, but it was balanced, and the driveshaft angles were good, as previously discussed. One last time, we reinspected the driveshaft. Only this time, we noticed the transmission mount looked cracked and aged. Grabbing the transmission tail shaft and pushing upward resulted in movement, and we were sure the mount was the source of our problem.

Above: The mounts were very similar. Although it appears the original mount had compressed dramatically over the years. The YearOne mount was significantly taller. Due to the height difference, we were concerned our driveshaft angles would be affected.

We contacted YearOne about a new transmission mount. YearOne had the factory-style rubber transmission mount we needed (part no. FD33145). The transmission mount fits all 1965-1973 A-body automatic and manual transmission models and 1962-1971 B-Body Chargers, Road Runners, and Super Bees with automatic and manual transmissions.

Above: The original mount had several minor torn and cracked areas and the compression concerns mentioned earlier. We doubt it is the original mount, but who knows? We did find a faint Mopar part number on it, but it did not show well in the photos.

We removed the driveshaft loop installed in May 2019 to start the removal process. It was held in place by two of the four transmission cross-member bolts. We supported the tail shaft with a jack stand with the driveshaft loop out of the way. Two bolts were removed from the transmission mount at the point where they were attached to the transmission. Lastly, we removed the remaining two bolts that held the cross member to the chassis.

Above: To check the driveline angles, we had to support the weight of the Dart’s rear on a pair of jack stands. To ensure the Dart did not flip off the vehicle hoist, we added a jack stand to support the front of the Dart.

With the cross member on a workbench, we unthreaded one last fastener and gently pried the mount from the cross member. As expected, the mount was tired but did not look too bad. We were sure the mount was the problem, but we were not overly confident when we witnessed its condition. We compared the YearOne transmission mount to the used mount, and the two were identical in all dimensions except the height. Our old mount appeared compressed compared to the new mount, so we planned to check the driveshaft angles upon completion of the installation.

Above Left: We made all the driveshaft measurements with the same inclinometer we used when we installed the 8 3/4-inch rear end in 2020. Above Center: The front slip yoke angle changed about 0.5° from our previous measurements. With all the remaining angles staying the same, the 0.5° change was not enough to cause us concern. Above Right: After completing all the measurements, the driveshaft loop was reinstalled.

The YearOne mount dropped into place in the cross member. We reattached the fastener to the new mount. The cross member was repositioned in the chassis, and the outer bolts were installed. We installed both transmission bolts through the mount and into the transmission, and then we removed the jack stand.

Before we lowered the Dart, we supported the rear-end housing with jack stands and rechecked the driveshaft angles. Although there was a slight change in the slip yoke angle, we determined the working angle at the transmission had changed by less than 0.5° from its previous measurement. The difference was minor, so we did not feel an adjustment was necessary. Finally, we reinstalled the last cross-member bolts and remounted the driveshaft loop. Lastly, we torqued the transmission bolts and all four cross-member fasteners.

Above: After the new YearOne mount was installed, we hit the road again, and this time, there was no vibration at all. The Reed tach proved the vibration was gone. The Dart cruised much smoother than it had prior. Although the Dart is always a pleasure to drive, it was excellent with the new transmission mount.

On our subsequent test drive, the vibration was not felt when accelerating or cruising. We also observed the Reed tach, and it showed the 1900 rpm vibration was gone. Since the repair, we have not experienced any vibration concerns. A simple transmission mount was the cause of our minor vibration.

Above: We used the tire revolution chart for our mathematical calculations with our Reed tach. (Courtesy of Chrysler Corp.)

As your Mopar ages, parts will fail even when they appear in decent condition. Check out YearOne to get the components necessary to keep age-related parts failure from disabling your Mopar.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by