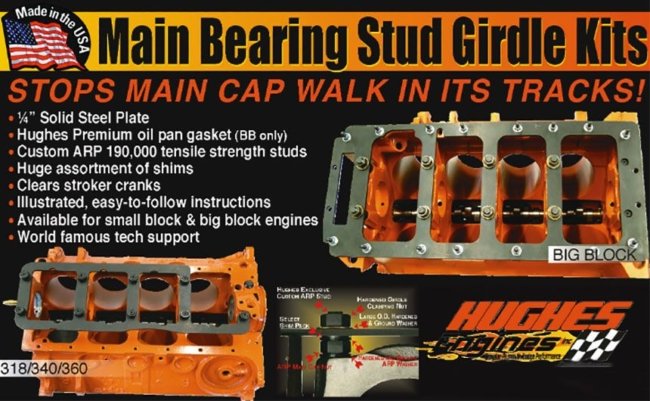

The inside of a running engine is an incomprehensibly chaotic and violet place. If you could lay inside an oil pan and look up at a built 440 big block spinning 6,000 RPM, what might you see? Aside from the terrifying whir of a cooking crankshaft, connecting rods that are doing their best not to turn into pretzels, and hot oil being slung in every direction, you might be surprised to notice that the bottom end of a girdle-less block is barely holding together. Hughes Engines has the fix with their main stud girdle kits and their Tech Center can explain how they’ll help:

Main bearing girdles were first used on supercharged Small Block Chevy’s in the early 60’s. When the heavy-duty 4-bolt blocks became available they disappeared. The 5.0 Ford started splitting down the middle about 10 years ago and the main bearing girdles again made their appearance. All of the new power-producing parts such as strokers, high flow heads, manifolds, and camshafts available today severely over stress the stock Mopar blocks. The ‘good’ cross-bolted factory Big Blocks and the 4-bolt 340 blocks are in limited supply at best, or nonexistent. This leaves you with 2 options: our main girdles or – “that can’t be good” – Bubba!

The beauty of these kits is that you can use the original main caps, which will only require line-honing. This drastically reduces the cost of the job and gives better support than other methods to boot – a true win-win situation.

The main bearing girdles are used to tie the main bearing caps and bulkheads together, thereby stiffening the block lower-end and increasing crankshaft support. Our stud girdle is designed to reduce fore and aft and lateral block movement (that means front-to-rear and side-to-side for the chatters). We are not trying to prevent bending of the block with the girdle.

The thickness of the girdle has very little to do with its strength. Its strength lies in its width rather than its thickness. For the vertical strength (thickness) to be a factor, the plate would need to be 1.5″ to 2″ thick and have the caps as an integral part of the girdle. Many newer OEM engines are made this way and that is a good design, which cannot be duplicated with a flat plate. In addition, if the plate is too thick, it makes oil pan removal more difficult in the chassis.

When the engine is running, especially under highly loaded conditions, the crankshaft is being twisted back and forth trying to move the main caps and bulkheads along with it. This crankshaft twisting is the reason for needing the harmonic damper. When the power output (twisting) becomes great enough the main caps will move “walk” against the block causing fretting (micro-welding). If this continues long or hard enough, the caps and/or main bulkhead can crack. Worst-case scenario: the block will split up through the cam bores.

Our girdles provide additional support points below the crankshaft and tie all the caps together substantially reducing any possibility of flexing or twisting. Testing (pre and post girdle) has shown power increases in engines with severe twisting (binding) situations and longer component life with the girdle installed.

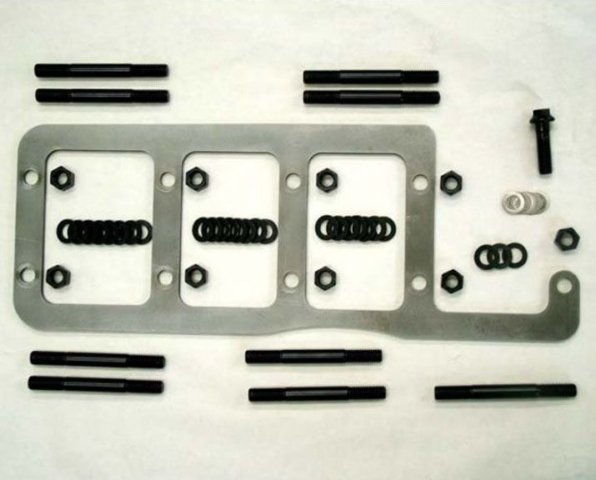

The small block kit can be bolted on with no machine work required. There is also an option of machining the caps for increased clamping area. Instructions for both applications are included. The big block girdle ties the main studs into the pan studs and block skirt area, too, and there is no machine work required.

All kits are complete with studs, shims, spacers and nuts and, as always, our real world, easy-to-follow instructions. The kits are supplied with studs for their superior clamping ability. When installing studs, the block must be line honed, unless it was previously line honed with studs. Using longer studs will not have an effect.