Long before the widespread use of overhead camshafts, the pushrod was the peremptory middle man for a great many valvetrains. Transferring motion from the camshaft via lifters, pushrods were and still are the least sexy part of the clockwork that is valve timing. Both boring and basic in shape, they’ll largely go unnoticed until the dreaded day that one fails to stand erect.

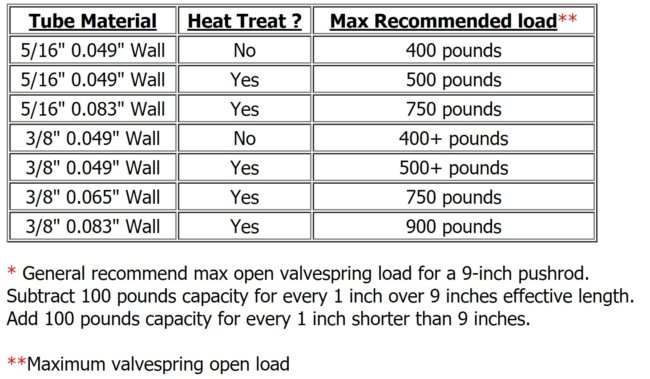

Nonetheless, pushrods play a vital roll in the success of surrounding components, be it rocker arms or even cylinder heads. Therefore, they more than deserve their fair share of the blueprinting process. Part of that is calculating pushrod load and capacity, especially in the modern age of big roller cams, high-flowing heads, and meaty valve springs. This handy reference chart from Hughes Engines is ideal for that end of it. Pushrod clearance, though, is just as important and requires this old school trick from the Tech Center:

We have received several sets of aluminum heads to C.N.C. port from customers in which they have cut way too much material out and the porting breaks through into the over-clearanced pushrod tunnel. This can be repaired but it is neither easy nor inexpensive.

Contrary to popular opinion, pushrods do not need clearance. In fact, it is a positive situation when the pushrods touch the heads. It reduces the potential for harmonics and flexing. The question is, ”How much and how hard can the pushrod touch and still be ok?”.

We test this in our shop using masking tape. We run a single layer of standard masking tape down the side of the pushrod. We then install it and rotate the cam several revolutions. If the tape does not tear, the clearance is just right. If the tape tears, you need to remove just a little more material.