(Photography by: DH Photo Concepts)

(Photography by: DH Photo Concepts)

For those of you out there reading along that haven’t been deep in the Gen3 game since 2005 when the Hemi started getting crammed into passenger cars, you probably don’t know of the troubles many of us have endured to get to where we are today. When the platform hit the streets it was a brand new product with zero aftermarket products or support.

This made competing against the other V8’s on the market challenging, as they had been out for years. It was tough in the early days to get a modern Mopar into the 11’s, 10’s, and 9’s in the quarter mile. It was frustrating, exciting and challenging. It was definitely not an easy task to push a new platform beyond what it was made to do.

Back in the day, the LX Forums was the place to be for all things Gen3 Hemi. Anyone who may have been part of that crowd may remember a user named HemiC. You could say he was the original trailblazer for pushing the platform to new heights every year. Chris Dufrense (aka “HemiC”) secured many “firsts” back in the day when it came to running these heavy bricks down the track.

Chris put racing on the back burner and seemingly vanished from the scene. Now he is back and bigger than ever; tackling the A, B, E-body Gen3 Hemi craze in his own way. Just like the early LX days, his efforts aren’t going under the radar.

The early days for Chris started as a teenager doing backyard engine swaps, garage rebuilds, and porting heads in high school shop class. Chris says, “I would use whatever performance parts I could scrounge up at the local swap meets. This was all done in the name of getting an edge in the street light action taking place in town and at Lebanon Valley Raceway.”

They were an all GM family growing up with a mix of Chevelles and Camaros, but always had an oddball family member and a friend or two that were true “Mopar or No Car.” The Gen3 Hemi and drag racing is what finally converted Chris to the “Mopar or No Car” family. After seeing those cool Dodge/Chrysler Hemi commercials and a couple test drives, he bought his first brand new car, a 2005 300C with the 5.7 Hemi.

This was a mid-2004, so not many were out yet. It was a solid performer which became the start of the addiction to the Gen3 architecture. The car ran 13.9 @ 99 mph bone stock, which was pretty stout for the platform. It quickly became an example of what you could do with a heads and cam bolt-on car; eventually becoming the first 5.7L Hemi in the 11’s in fall of 2006.

[For those unaware, the 5.7L Hemi from 2003-2008 only made 345BHP before it got some makeovers for the 2009+ production year, increasing power to 375BHP in the cars thanks to new “Eagle” heads and 390BHP in the trucks with the addition of an active intake manifold – Ed.]

Chris thinks back to the early days, “This was an epic year having fun battling it out at the events and comparing progress online through the forums with folks like Jim Meister, Al Kral and several other notable 5.7 trailblazers.” Right about this time High Horse Performance had begun putting on some test & tune events and Gen3 Hemi competitions.

These were the predecessor to the Modern Street Hemi Shootout (MSHS) series we have today. That little 5.7 with a Franks Racing (FRI) cam, FRI’s hand ported heads and a Pro-torque TC brought home the bacon numerous times and became the springboard for the next “HemiC” project; a 2006 SRT8 Magnum with boost and juice (aka “the Fat Bottom Girl” or FBG).

FBG was a great example of what Drag & Drive really meant. A true street car. Chris and his family had so many memorable trips packing the entire family into the car for these far off events, swapping some tires, tune, race gas, and kicking ass. Then, continuing on with family vacations in the FBG to Florida, Canada, or cross-country. A modern day Clark Griswold with the family packed in the wagon!

Like many others, Chris had to balance his race life with real life. Somewhere around spring/summer 2010 real life took him out of the game for a bit and carried him to some fun places like Afghanistan, and an assignment in the United Kingdom where he spent the better part of five years (2011-2016).

Chris tells us, “It was 2019, and I was driving a Trackhawk thinking it would be my tow vehicle to haul a fully dedicated race car. I have always loved the sharp clean lines of the ’64-65 B-bodies, its unique rear pillar and iconic wrap around rear glass design coupled with the fact that this chassis defined FS/FSS/FX racing back in their day.”

The move to the ’65 Coronet represented the perfect opportunity to embrace my eternal love for 60’s muscle cars and the growing Gen3 Hemi architecture. At the end of the day, it was the perfect car at the perfect time for me.” The ’65 Coronet (aka Homebrew) was found after searching for almost 6 months.

Chris struck gold when he found this gem on Racingjunk.com located just a short skip from him. It was sitting at a fab shop waited for a new home. Fusion Fab had just finished updating the chassis on the car intending to race in Ultra. Chris bought it as a roller which made it the perfect blank canvas for MSHS Outlaw racing with the Gen3 Hemi.

The primary goal with the start of this project was to get back to heads up racing. Chris wanted to stay true to the “run what you brung and hope that you brought enough” tradition. It had to be something that would allow him to be competitive in MSHS’s top dog class as well as participate in some of the local 1/8 mile events which continue gain popularity.

A secondary goal was to build towards a combo it could also be configured for the occasional Drag and Drive events (ala Sick Week, Motor Trend‘s Dragweek). Chris has a soft spot for this approach to racing, stating “This, in many ways, represents the ultimate test of man and machine in drag racing. It’s a bucket list thing for me which I hope to fulfill in 2023”.

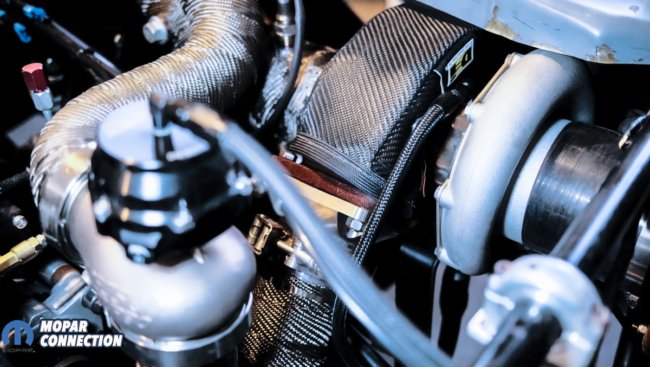

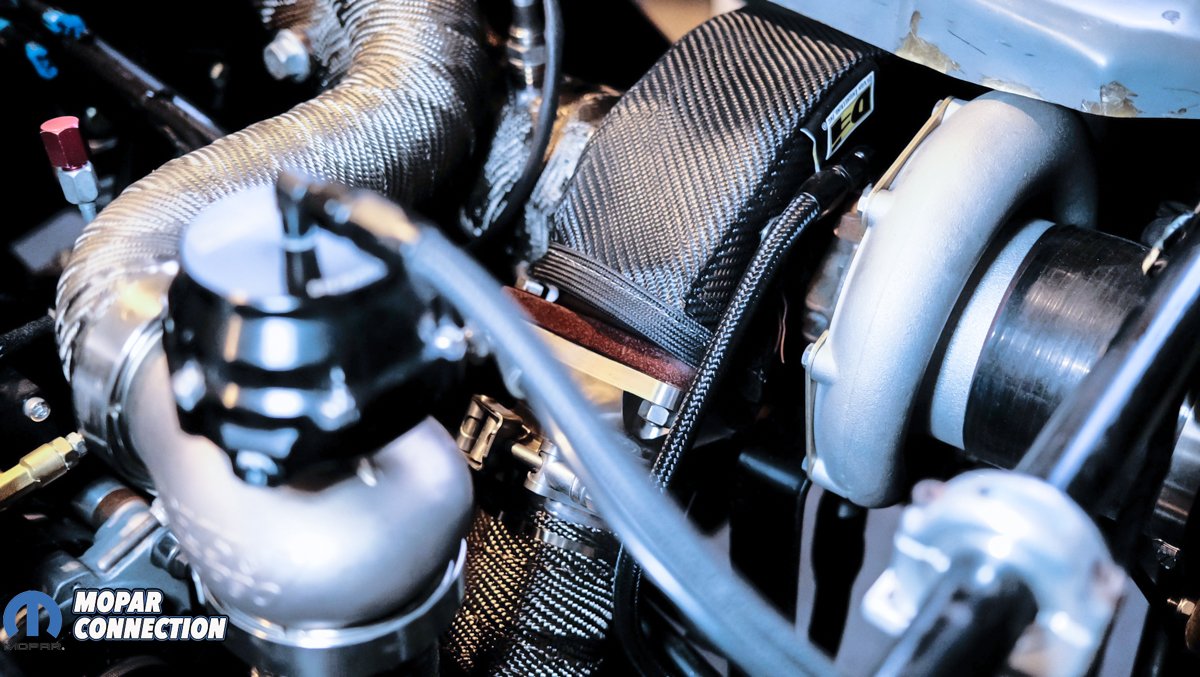

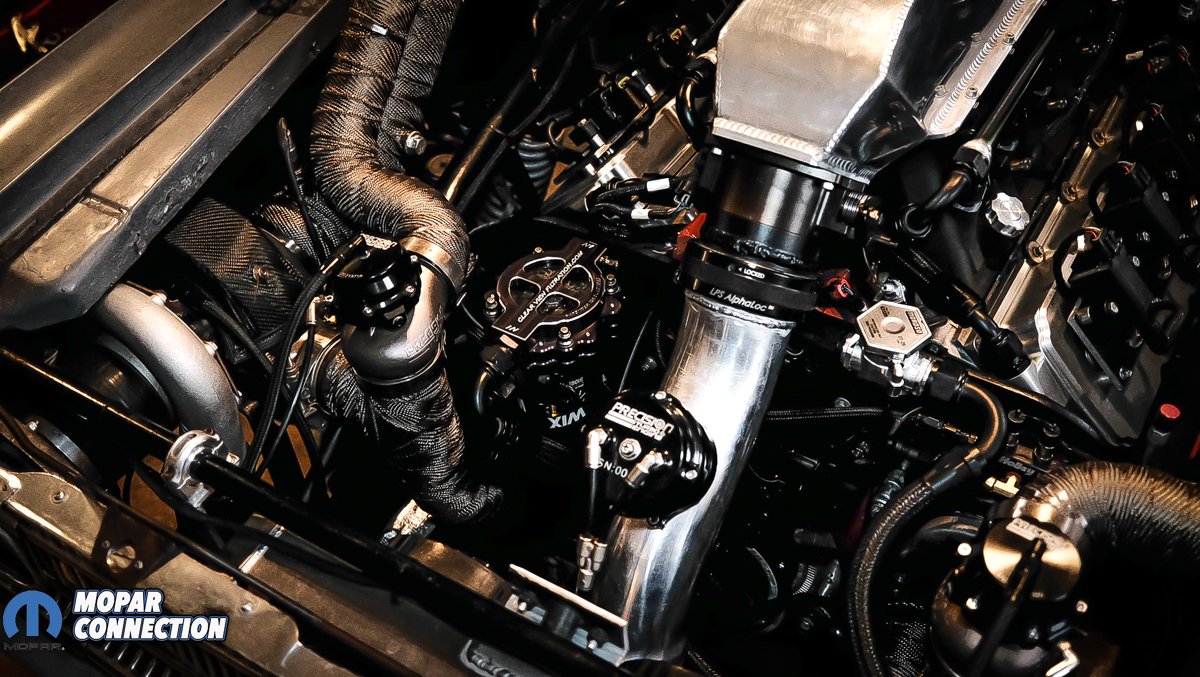

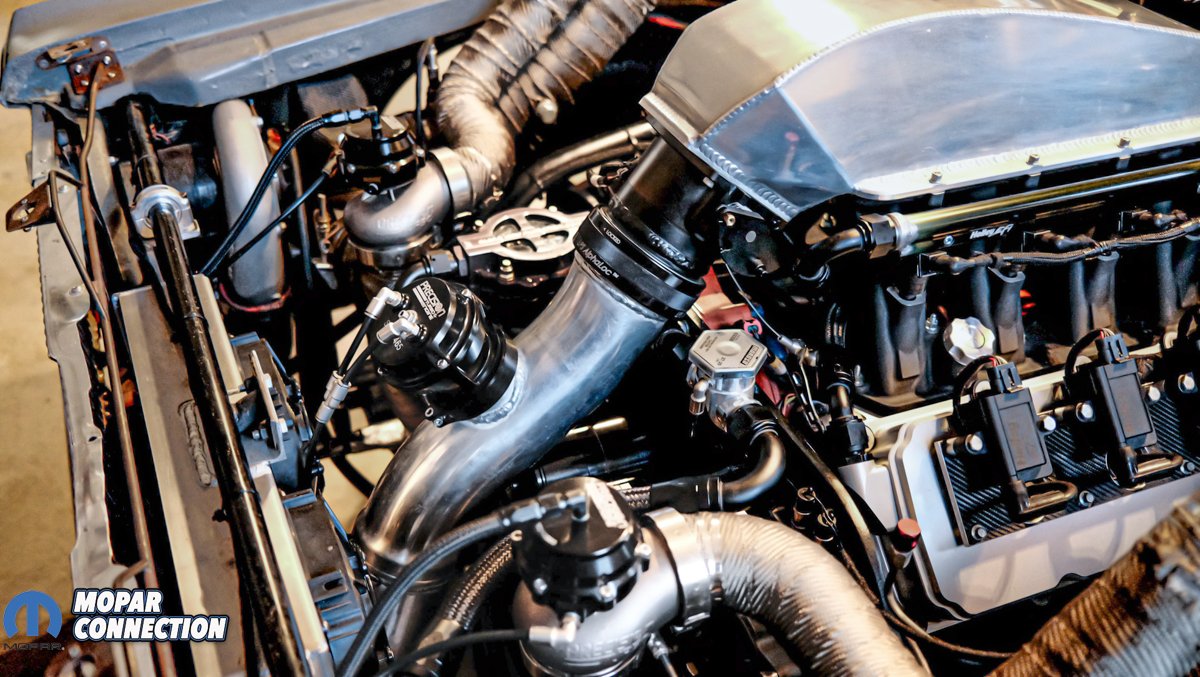

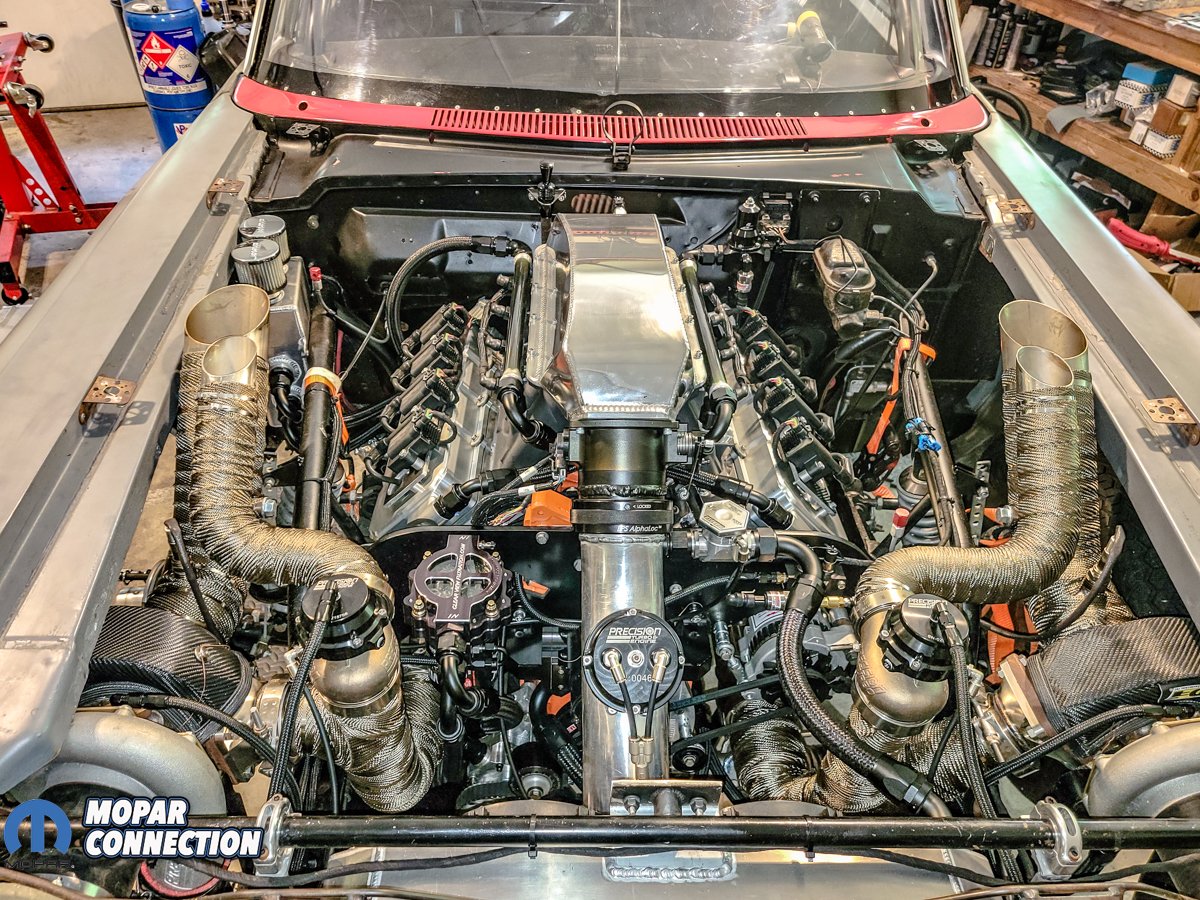

The Coronet came to Chris as a roller with an updated chassis and funny car cage, firewall-forward tubular front end utilizing stock frame rails modified for coil-overs, a stock K-frame modified for a manual rack and pinion steering, a removable nose, ladder bar rear, and Lexan all around. This made for a solid foundation for him to fuse with a home built twin turbo, 378ci Gen3 combo.

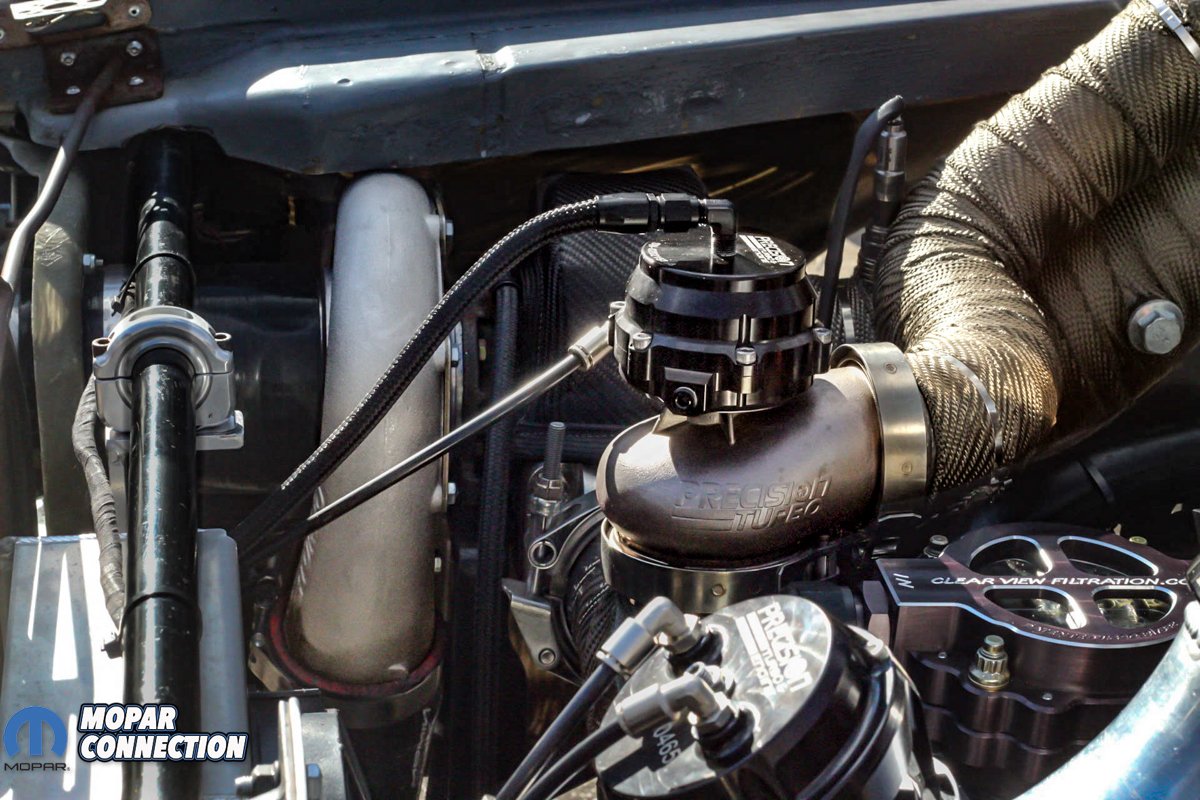

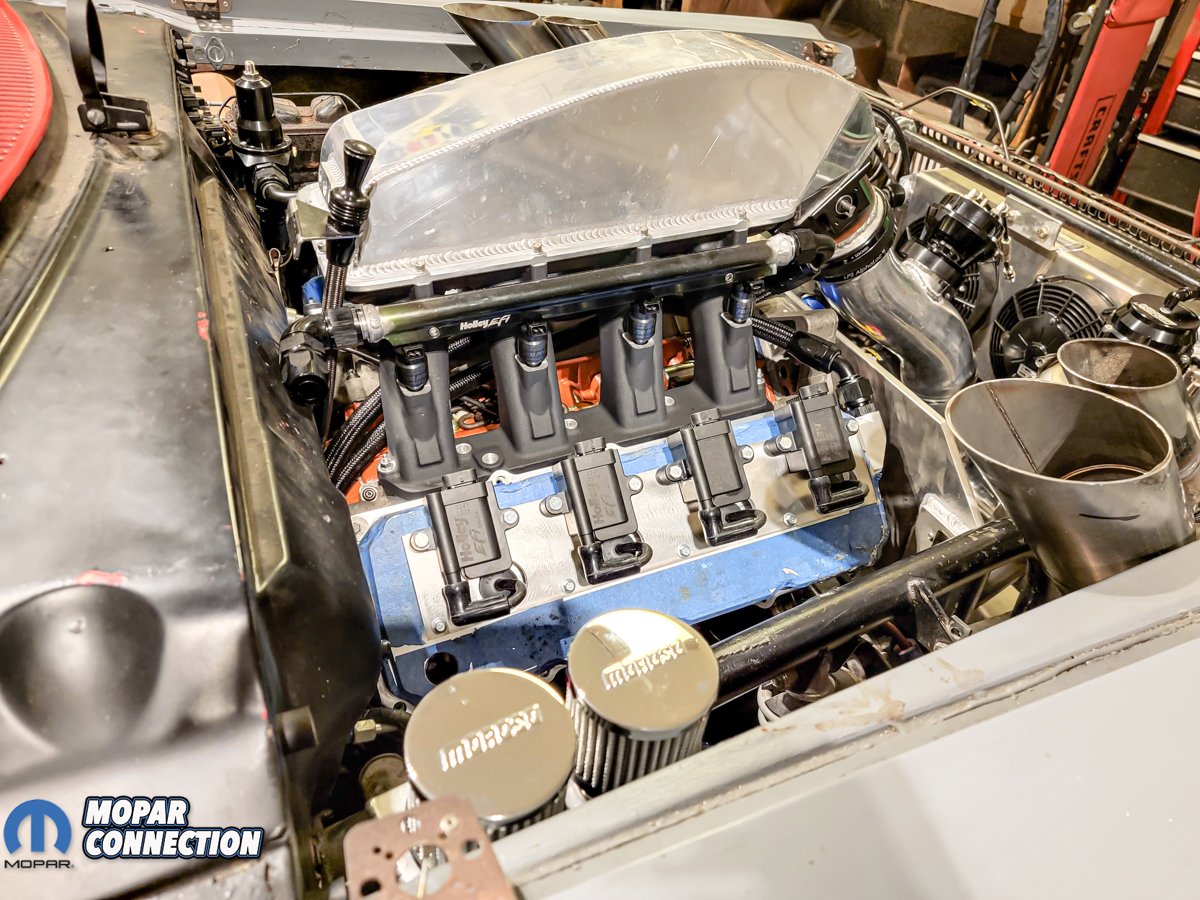

The goal was to build enough steam to push 3300lbs to mid 7’s in the 1/4, and mid 4’s 1/8th, on a “budget.” The engine combo is essentially two of Precision’s inexpensive LS 76/75’s on a 3/4 filled OEM Dodge BGE block, factory Demon crankshaft, some MGP billet aluminum rods, custom Diamond pistons, and a custom designed cam from Cam Motion.

Up top sits a Holley High Ram intake with 700GPH atomizers. The headers were built from a $200 set of eBay LS turbo headers with Hemi flanges. Drivetrain consists of a Rossler 4L80E and a Circle D converter. Out back sits a Strange Ford 9″ with a spool and 4.30 gearing. The relatively simple combo has met Chris’s goals with quite a few clicks on the “boost knob” still left.

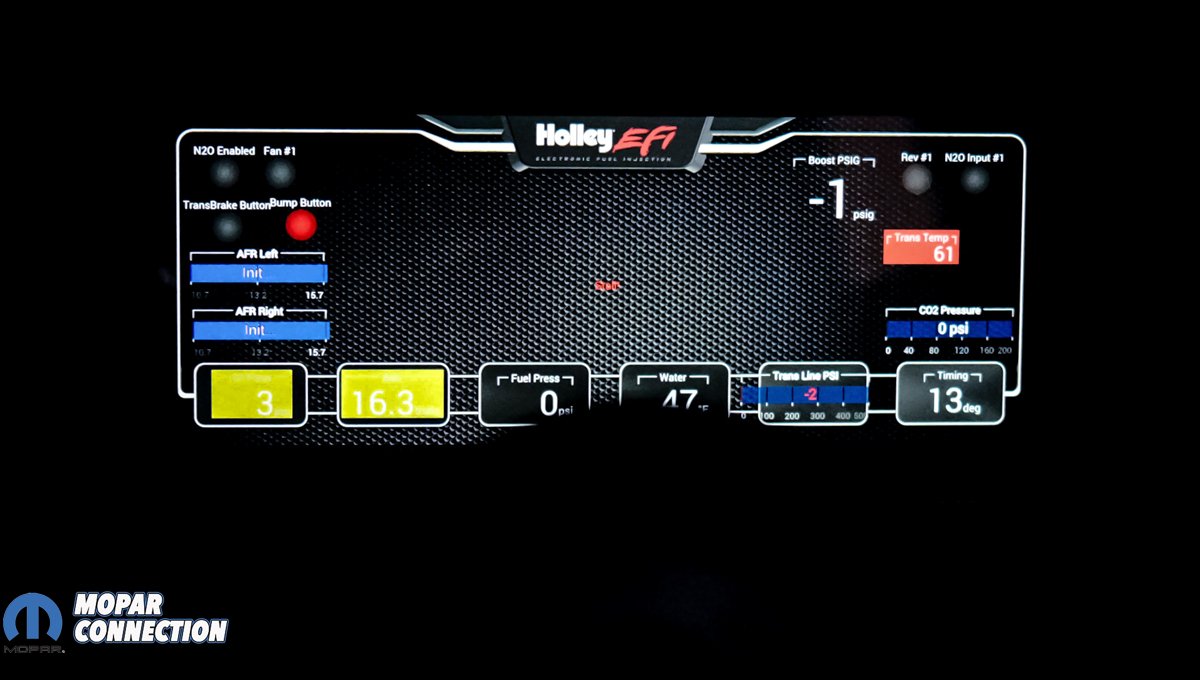

Chris mentions that it took almost 18 months to get to start up in the garage. “We worked with Joe at Tempest Racing to get this on his hub dyno for some engine break in and baseline set. He is always awesome to work with and over the course of one day we had the Meth tune sorted, safe and ready for fine tuning at the track.

After some break in pulls, we progressed the power pulls from 850-ish on the springs to 1680-ish at 30-31psi and decided to do the rest at the track. It helped that we previously built an almost identical engine combo for Dan Vanhorn’s “Deuce” so I was able to incorporate much of what we learned from our experience with his into my car.”

The fact that Chris and his rowdy bunch were able to push a production iron block to 2000hp is somewhat absurd. Chris doesn’t care to take the credit for it. “While we had experience building in the 1000-to-1300 rwhp range, this leap to the 1500-to-2000 rwhp level was a first for us. However, the principles of engine building do not change. Precision machine work is key here.”

“As such, I work with Ray Barton Racing Engines for all my machine work. There are few before me who helped blaze the trail showing the potential of factory 6.1, 6.4 and 6.2 BGE blocks but it’s safe to say at the time only a few were at this extreme level and even fewer that have proven themselves to last an entire season.”

“The fact is that there are still not many block options for those on a budget, so the decision to go with the BGE block with its thicker decks, main webbing and revised coolant passages was a no brainer. The BGE block has exceeded expectations in every way.” You won’t read a lot of info on building a setup like this on the Hellcat forums and Facebook groups where you often find “reinventing the wheel” as a means to go fast.

One of the beautiful things about the Gen3 Hemi is how much of it is still backwards compatible. It utilizes a SB Mopar bell housing and block dimensions that ended up within 1-inch of the BB Mopar that the Coronet’s chassis/engine plate was built around. Chris’s setup utilizes AEI front and mid plates, which only required minor adjustments in spacing to close that gap.

The width of the engine and front sump pan can be an issue for this type of retrofit but given the 65’s coil-over conversion with tubular front chassis, K-frame kit and drag pak style rear sump pan, Chris had zero fitment issues. Overcoming challenges in maintaining the fuel volume of methanol required at this power level and consistent oil pressure on 2.5g launches led Chris to implementing a Peterson external oil pump fed from the Drag Pak pan rear sump, and a cable drive extending to the mechanical Waterman pump in the trunk.

Aside from cramming as much powertrain as possible into a 60 year old tin box, the car had to see some chassis upgrades to not fall apart. Fusion Fab did an outstanding job updating the chassis while keeping factory front/rear frame rails and firewall intact.

According to Chris, “given the combo of fiberglass, tin, and original 60’s steel, I can tell you that you hear and feel every pulse of the engine, turn of the driveshaft and pebble kicked up from the tires. It is visceral and took me a bit of time becoming comfortable and confident this is not the car falling apart.”

“Thankfully it drives straight with the wheels up and under power and so far has recovered quite well from zipping tires at speed. I am still learning suspension and dialing it all in with shock/spring adjustments but I really can’t ask for much more from a hunk of iron that is 60 years old.”

One of the most impressive parts of this car is that this engine truly was built on a low budget, at home, with his own hands. We are talking a price tag at a fraction of the cost of most 600-plus horsepower SBM builds out there. We are looking at an engine cranking out 2000hp to boot. It seems like a risky move that has repeatedly paid off.

Chris says, “Partnering with a quality machine shop like Ray Barton’s has provided that precision machine work delivered to my specs consistently. Having good instruments to then set, measure, and verify clearances associated with every component is key (ring gaps, rod/main clearances, piston to cylinder wall and piston to valve clearances, accurate torque settings/bolt stretch/angles, block clearancing etc)”

Chris continued, “…and with that, a network of folks that can help you overcome unforeseen obstacles in these one off builds (ie. making a fixture to drill rod Gen3 Hemi/SB Mopar rod bearings with dowel pin holes for the aluminum rods or the integration of tool steel pins for retaining VVT timing gear, etc). There are no shortcuts and often no ready made solutions at this power level.”

“In terms of survivability, an equally important part to the build itself is then how that combination is managed under power. Having good data, reading plugs constantly to put that data into context and perhaps most importantly having the restraint to safely creep up on that tune will save a lot of hardware and heartache.” The fact that someone can build an OEM iron block, in their garage, at this power level, and last multiple seasons, is nothing short of mind blowing. Again, showing that you don’t always have to reinvent the wheel.

Air is going right over the headlight where they stuck the turbo inlets.

“Can you say boundary layer effect? I knew you could…”