Cold air induction was the key to immediate performance gains in the 1960s. Muscle cars equipped with such options brandished names like “Ramcharger,” “Cowl Induction,” “Ram Air,” “Air Grabber” and the like, but all offered the same innovation: cool, dense air being pulled from outside of the engine compartment. Hoods featured a variety of scoop and bulge profiles, as well as chrome-bezeled inlets either below the front bumper or even replacing a center set of headlights. Either way, drawing in outside air was a quick fix for horsepower; and its benefits are being touted even today.

Although functional, even Mopar’s Air Grabber and Ramcharger air induction systems on the 1968-1972 B and E-bodies required air to travel a circuitous route before passing through the paper-and-steel filter screen, and eventually passed the carburetor’s throttle valves. Not only did this slow the rate of flow for incoming air, but it also managed to pre-heat the charge, mitigating much of its initial benefit. Thankfully, modern filter technology has freed up much of that lost velocity. Frankly put; the shorter and more direct the path, the faster and cooler the intake charge will be.

Above: Our ’69 Dodge Charger project “Brazen” has been in hiatus for a year now, as we finish up a transmission swap, Gear Vendor upgrade and a complete head-to-toe rewiring project. So we figured, “Why not build a cold air box instead?”

A couple of years ago, Hot Rod Magazine’s dyno challenge show “Engine Masters” performed an air filter shootout. While the results were somewhat to be expected, the biggest revelation was the successful rate of power gained by a carburetor (or traditional plenum-style throttle body) using an air filter that allowed air to pass straight down, rather than passing over the throttle body from the sides). This means that for a factory-style Air Grabber or Ramcharger cold air induction system to work optimally, replace that big orange decorative air lid with a modern performance air filter lid.

For our 700-lbs. ft. of torque 535cui. stroker – what we’ve called “The Wicked Wedge of The South” – powering our ’69 Dodge Charger R/T “Brazen” project car, feeding it as much fresh air possible was paramount. Certainly, our massive A023 Hemi Dart barn door scoop and two-pin hood from VFN Fiberglass could funnel in all the outside air as the 535 could take, but only when rolling at speed. While at the stop light or even cruising in slower traffic, a lot of our engine’s air intake was being drawn in from the engine compartment, which could be broiling hot even with both Spal fans at full blast.

Because of the uniqueness of our Charger’s build, we knew factory components just weren’t going to fit. Looking online, we found Allstar Performance, who specializes in dirt and circle track race car components. Allstar produces a Universal Air Pan made to fit most 14-inch air cleaners specifically for creating a cold air box. This was exactly what we’d need to seal off our air cleaner assembly from engine heat. The Allstar pan measures 18-inches by 4-inches, and includes a silicone seal to sit in the air cleaner base with the pan sitting on top.

Unfortunately, the ’68-’70 Dodge Charger hood features two faux louvers, that together with the substructure make for a complicated surface to match. Add to that the factory off-set of the engine favoring the passenger side, the forward pitch of the hood and the reverse angle of the engine, and we were looking at a custom-tailored job for sure. It took two days of trial-and-error fitment, trimming and trimming and more trimming until finding a height that didn’t bind or directly contacted the hood. Because we’re running a tall single-plane Edelbrock RPM Performer intake, we trimmed nearly 3-inches in some places.

Originally, Allstar’s instructions were to place the seal into the bottom of the aluminum base before setting the air pan onto the seal. Since we needed the hood clearance, we reversed the order, and had to rivet our aluminum base to the inside of the air pan. This bought us about 1/2-inch of clearance, which was enough for us to use some C-channel Trim-Loc trim seal. The flexible PVC trim features internal aluminum metal clips excellent grip retention, and durable EPDM foam rubber to drown out noise, vibration, and seal our air pan from the hot engine compartment air. We also drilled a drain hole to keep water from collecting.

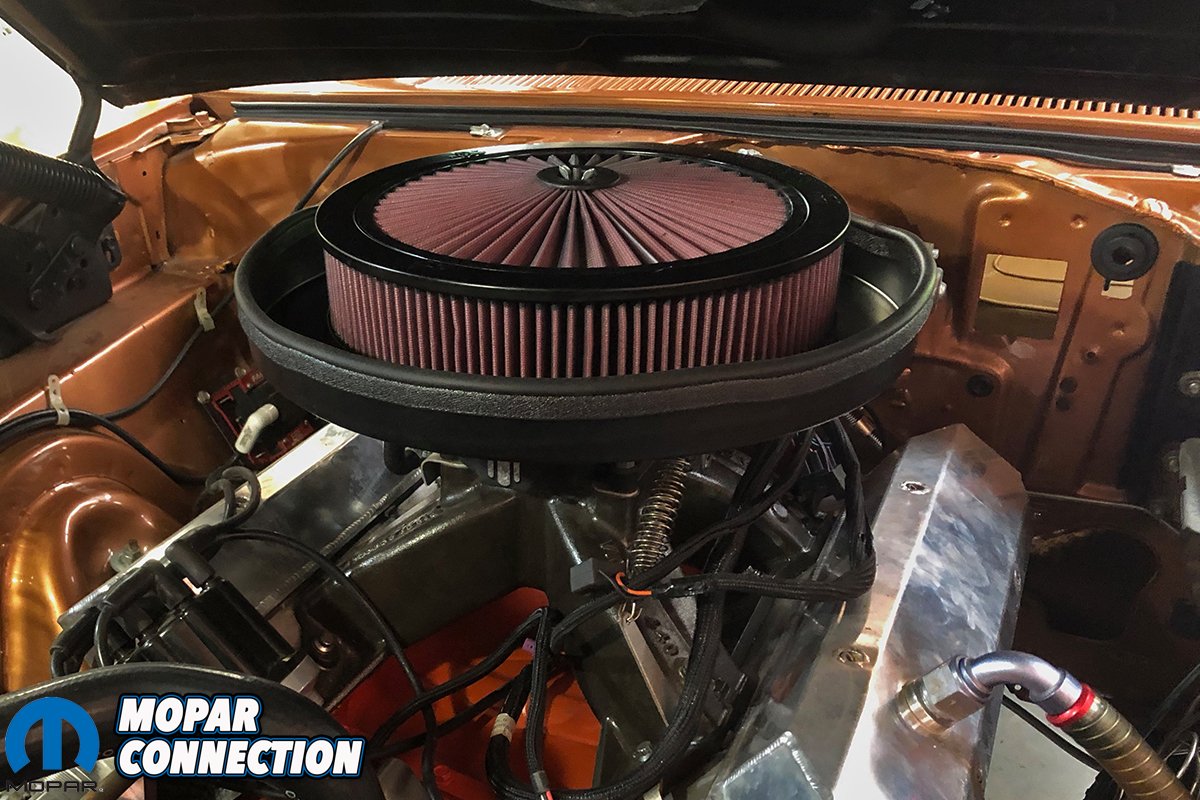

With our Allstar air pan perfectly matched to the undulating contours of our VFN Fiberglass hood, sealing our air cleaner assembly off from the engine compartment completely, it was time to dramatically step up our air cleaner game. To maximize the flow of clean, fresh cool air, we reached out to K&N Filters and picked up one of their X-Stream Air Flow filter assemblies; replete with a 14-inch aluminum base, 4-inch pleated, washable and reusable fabric filters and topped with their X-Stream Top Assemblies featuring the same proprietary K&N Filter material to allow the maximum flow into the throttle body.

Best of all, both filters can be used for years beyond conventional paper filters, as they are washable; just order the K&N Filter Care Service Kit to clean and re-oil when needed. This way, our FAST EZ-EFI 2.0 could draw in fresh, cool outside air from all directions, passing through the industry’s most trusted performance air filter. We now had successfully transformed our Hemi hood scoop into a open-sided air box, directly feeding our 535cui stroker with all the outside air it could ever want – and completely sealed off from the super-heated atmosphere under the hood.

I ran across a similar problem with my ’70 T/A….only in those days (decades ago) the only thing available in the aftermarket was a 440 Six Pack cleaner assembly with no gasket to the hood.

Your solution may not be perfect, but much better than I ever had. Well, done, bro, as I am sure you were getting tired of trimming back that air pan.

LOL. Yeah, there was a LOT of back-and-forth. Thanks for the positive words!