Depending on what you’re doing with your Mopar and what your goals are, you may find yourself needing a few more amps to power all of the goodies in your car. Our ’72 ‘Cuda has a decent stereo system, dual electric fans, MSD ignition, lights (of course) and a working heater system. Although the AR Engineering 60 amp Denso alternator kit we were running was nice and compact, it just couldn’t cut it anymore when we added dual Spal electric fans; so we began searching for a more powerful alternator.

After a little research, we decided to try the Mopar 110 amp one-wire alternator. Available in three options for finish (natural, chrome and black), we opted for the natural finish (PT# 440-471). Once it arrived, we were impressed with it’s appearance; it looks great, appeared well-built and the pulley turned smoothly with no apparent runout. As far as an out of the box inspection goes, it passed our sniff test.

Please note that this is a one-wire alternator, so if your car is not set up for a one-wire unit you will have some wiring modifications to do. Always make sure your electrical system can handle higher amperage alternators before upgrading as well. Our ‘Cuda has a Painless wiring harness in it with appropriately-sized wire gauges and took minimal modifications to switch over to a one-wire configuration. Your mileage may very, so make sure you do your research ahead of time!

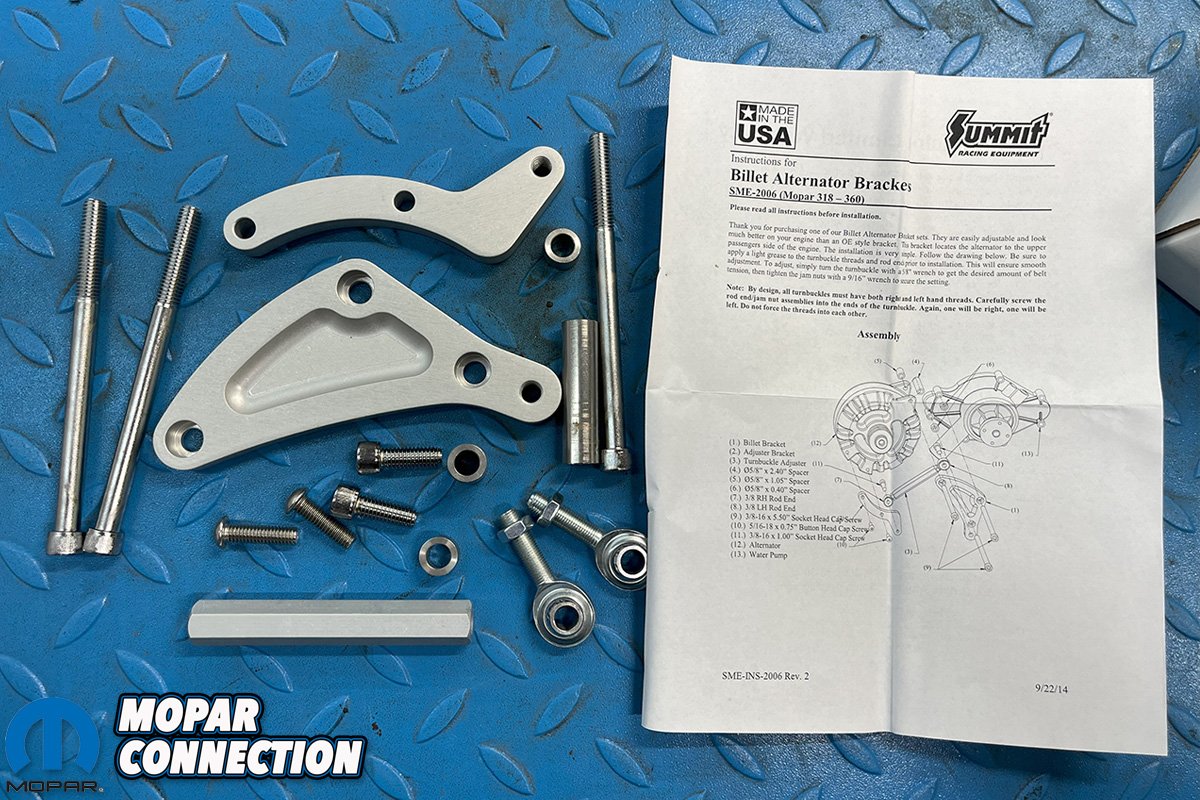

In addition to an alternator upgrade, we needed some brackets, since we had the non-OEM style Denso alternator in the car previously. After some digging on Summit Racing, we discovered the SME-2006 bracket kit and thought it looked really slick. The brackets looked sturdy and included a heim joint adjustment for tensioning the belt versus the old “pull on the alternator as hard as you can, then crank the bracket bolts down” method.

Like the alternator, we were impressed with the quality of the parts included in the bracket kit. A quick glance at the instructions and we were ready to turn some wrenches. We of course, started with the removal of our Denso unit and brackets, which attached just like OEM style brackets. To disconnect the wires from the alternator, we used a 13mm wrench to remove the bolt in the slotted section of the alternator bracket and slide the belt off (we left it hanging in place).

A 9/16-inch wrench was used to remove the bolt, which passes through the alternator ear/bracket and into the cylinder head. The 9/16″ wrench is also used to remove the nuts holding the small bracket to the water pump bosses. We used studs during the assembly of our engine for the timing cover and water pump, you may have long bolts in yours instead.

The directions with the new bracket kit are laid out well and the diagram is easy-to-follow. Those nifty studs we used during our engine assembly needed to be pulled out and replaced with the longer bolts that came in this kit. Next, we used a 5/16-inch Allen wrench to attach the heim joint end the back side of the bracket that attaches to the water pump bosses.

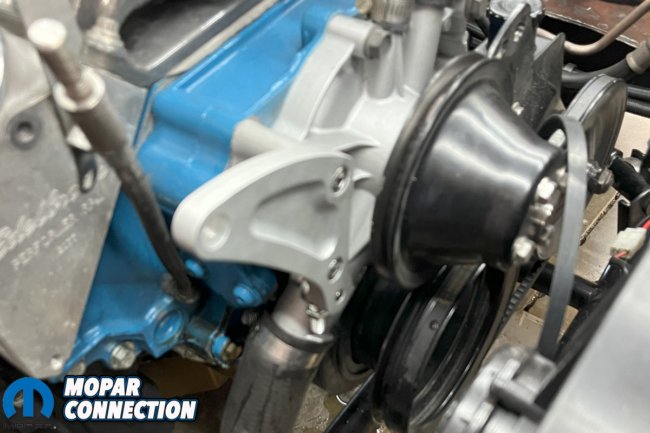

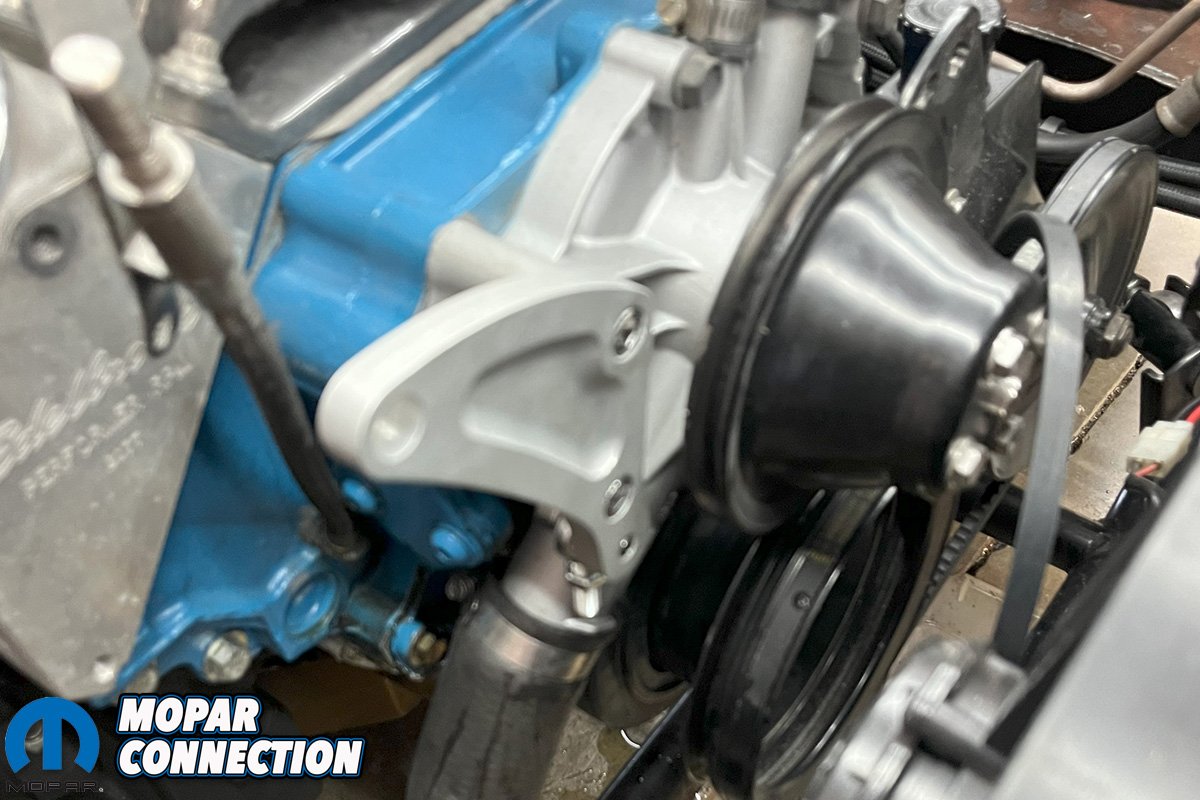

Then we mounted that bracket to the water pump, leaving the heim joint hanging. We made sure to follow the diagram and use the spacers that go behind the bracket during assembly, and added a little thread sealant since these bolts do go into the water jacket. Using a 5/16-inch Allen, we tightened the bolts up as they will not need to be loosened for belt adjustments like factory style brackets.

We mounted the other end of the heim joint to the alternator bracket using a 5/16-inch Allen wrench, and bolted the bracket itself to the alternator using a 3/16-inch Allen wrench with the two supplied bolts.

Next, we hung the alternator by using the spacers and long bolt as shown. Our heads are aluminum, so we were sure that the bolt threaded in nice and smooth to avoid any potential cross threading. Using the 5/16-inch Allen wrench we just snugged this bolt up for now as the alternator needs to pivot on this bolt during adjustment.

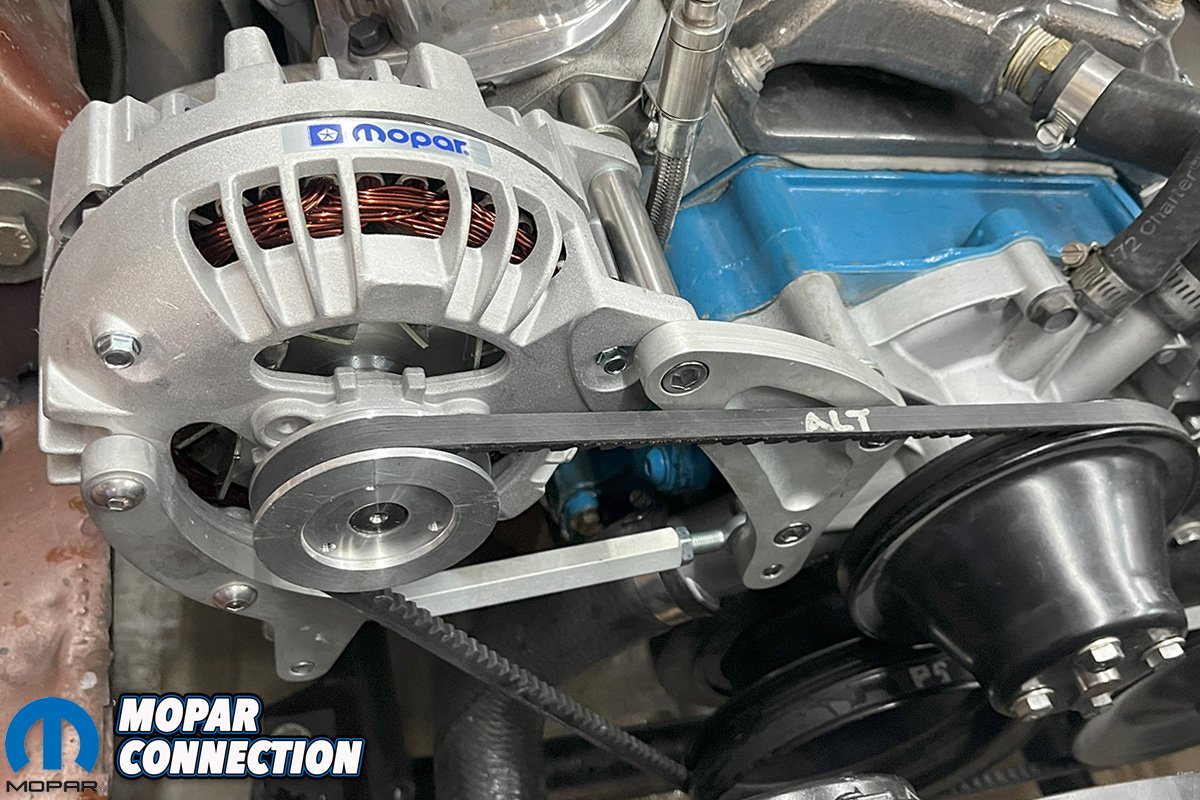

With everything hanging loose, we spun the heim joint connecting bar together with the heim joint ends. Step 7 we put the belt back on the pulleys and began adjusting the belt tension using a 9/16” and 5/8” wrench on the turnbuckle bar / nuts. It was very satisfying to tension the belt in a controlled manner like this!

When the belt was tensioned to the point where it had about ½ inch of deflection when you pressed it down with your finger we stopped adjusting, tightened up the turnbuckle and tightened the long bolt going into the cylinder head.

The last thing to do was to reattach our positive cable to the alternator and fire it up. Upon startup we were happy to see 14.5 volts. With all accessories turned on the alternator seems to stay in the 13.8-to-14.1 volt range which seemed alright to us. Much better than the 12.1 volts we were experiencing with the old alternator setup.

After running the alternator a little we did notice some belt squeal and ended up using a straight edge to check pulley alignment. We found the pulley not to be exactly in line which we assume is a product of our aftermarket aluminum water pump. A few washers strategically placed remedied the issue. So if you are not running factory style components be aware you may have a little fine tuning to do on the setup ! Overall we are very please with this upgrade.