Which intake manifold is the best? Is it a single- or dual-plane? Dave Hughes of Hughes Engines decided to set the record straight. Hughes built a stout 408 cubed engine, and then he optimized the timing and carburetor with each manifold. Other than the manifold swap and carb tuning, the engine remained the same, which kept the test variations to a minimum.

Dave Hughes of Hughes Engines fields dozens of questions a week about Mopar engine builds, but by far, the most asked question is, “which intake manifold should I use — a single- or dual-plane?” That is a loaded question that requires plenty of supplemental information before Hughes can provide a well thought out answer that will exceed the customer’s expectations. The question piqued Hughes interest to the point that Hughes Engines put together a stout small-block stroker to test two popular Edelbrock intake manifolds. The dual-plane selected for the test was an RPM Air-Gap, while the single-plane was a Super Victor.

The test engine was assembled with a 4-inch stroke crankshaft and a 4.03-inch bore, resulting in a 408 cubic inch displacement (CID). The engine had an 11.5:1 compression ratio that worked well with 92-octane pump gasoline. The cylinder heads were a Hughes modified “BigMouth” design with the pushrods moved over 0.200-inches from the stock location, which resulted in a 206cc intake port volume. The most recent design of the “BigMouth” heads has the pushrods shifted over 0.350-inches. The camshaft was a Hughes Engines design (part no. HTL 6468AS-6), and the valves were actuated by 1.6:1 rocker arms. The induction was handled by a stock 850 Holley sitting atop the previously mentioned Super Victor with competition porting work.

Above left: The Edelbrock cylinder heads have generously sized ports, and the out of the box airflow numbers (measured in cubic feet per minute) are decent. The Edelbrock heads ability to flow air is comparable to or greater than any Mopar stock cast iron cylinder head. Above right: Hughes Engines machines the cylinder heads for additional airflow. The heads used for the intake testing are known as “BigMouth” ports, which have the intake pushrods moved 0.200-inches from the stock location to improve airflow. Hughes Engines now offers a “BigMouth” head that has the pushrod shifted over 0.350-inches.

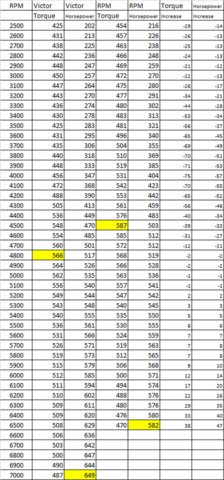

The testing started with an engine warmup and then several wide-open-throttle pulls on the engine dyno. The engine ignition timing and carburetor jetting were fine-tuned. After additional pulls, the 408 with the single-plane intake laid down 556 lb-ft of peak torque at 4800 rpm, and it produced 649 peak horsepower (hp) at 7000 rpm. The average torque from 2500-7000 rpm was 505 lb-ft of torque. The average horsepower over the same rpm range was 464 hp.

After completing the Super Victor intake tests, the Hughes crew swapped to the dual-plane Edelbrock RPM Air-Gap. With everything buttoned up, the engine was rewarmed, and, again, ignition timing and jetting were optimized. Several pulls were performed, and the results raised some eyebrows. The peak torque of the dual-plane equipped 408 was 587 lb-ft of torque at 4500 rpm. The peak horsepower was 582 hp at 6500 rpm. The average torque was 527 lb-ft, and the average horsepower was 455 hp. With the dual-plane manifold, the 408 was only tested to 6500 rpm as the higher revs did not improve any performance numbers.

Above left: The testing began with the single-plane Edelbrock Super Victor intake manifold. The 408 provided a peak of 556 lb-ft of torque and 649 horsepower. The engine averaged 505 lb-ft of torque and 464 horsepower over the sweep range of 2500-7000 rpm. Above right: With the dual-plane Edelbrock RPM Air-Gap intake manifold, the engine developed a peak of 587 lb-ft of torque, and the peak horsepower was 582 hp. The average torque was 527 lb-ft with an average horsepower of 455 hp across a 2500-6500 rpm pull.

A few noteworthy results were gleaned from the manifold testing. The dual-plane performance was superior to the single-plane at low rpm. It made considerably more torque and hp up to about 5300 rpm. Between 5300-6000 rpm, the two manifolds had similar torque and hp numbers (the single-plane with a slight advantage), but the single-plane dominated after 6000 rpm. Around 4000 rpm, the dual-plane intake outperformed the single-plane intake by 75 lb-ft of torque. At the same rpm, the dual-plane design made 57 more horsepower than the single-plane manifold. The single-plane bested the dual-plane at 6500 rpm by 38 lb-ft of torque and 47 hp. The single-plane’s numbers would have likely been more significant as the single-plane engine pulls continued to 7000 rpm, while the dual-plane tests ended at 6500 rpm.

After all the results were in, Hughes asked, “Now, to answer the question of which manifold should be used?” Hughes continued, “I’m going to use my favorite phrase, ‘trade-off.’ What are you willing to trade-off to get what you want?” If the vehicle is a race car with a high-rpm engine under the hood and is not going to see street driving (trailered to the track), the single-plane is a clear choice. Conversely, if there are gears of 4.11:1 or deeper, a mechanical carburetor (or a pair of carburetors), or the engine is spun above 5000 rpm, a trade-off for streetability with the single-plane will cost a couple of tenths at the track.

The dual-plane made more torque and hp up to about 5300 rpm. Between 5300-6000 rpm, the two manifolds had similar torque and hp numbers, but the single-plane dominated after 6000 rpm. Around 4000 rpm, the dual-plane intake made 75 more lb-ft of torque compared to the single-plane intake. At the same rpm, the dual-plane design made 57 more horsepower than the single-plane manifold. The single-plane outperformed the dual-plane at 6500 rpm by 38 lb-ft of torque and 47 hp.

However, on the street, do not try to “roll on the throttle” against a similar vehicle equipped with a comparable engine running a dual-plane. The dual-plane manifold’s low-end torque will thoroughly thump the single-plane resulting in you pulling off the main drag into a McDonald’s parking lot with your tail between your legs. Hughes stated, “You say I’m biased? You bet! Customers with any connection to the street are overwhelmingly happier with a dual-plane and a vacuum carb than a single-plane intake.”

The dual-plane manifold is the “King of the Street.” The engine will provide good manners and will be fun to drive. Hughes stated, “any customer with a connection to the street is overwhelmingly happier with a dual-plane and a vacuum carb than a single-plane intake.” If the car will only see time at the drag strip, and the engine is a high-rpm mill, then the single-plane design is the winner by far.

A few will argue that some header options could enhance the single-plane manifold torque curve. The headers could be swapped to a pair with a smaller or larger cross-sectional diameter of the primary tubes (also incorporate stepped primary tubes) or different collector designs and lengths. Changing the headers would result in another trade-off. If low-end torque is picked up with better low-rpm scavenging, the upper-rpm will lose horsepower. Hughes stated, “The single-plane guys are not interested in trading off any top end, and the collector work can also apply to the dual-plane intake, further embarrassing the single-plane in a roll-on race.”

Suppose the dual-plane intake crowd wants to increase top-end power; the septum (dividing wall under the carburetor) can be modified. The septum mods, however, means there will again be a trade-off. In this case, the low- and mid-range will suffer. Single-plane intake manifolds can have a low-end torque enhanced by installing a septum, but the trade-off is a loss of top-end power. “A

septum could be used as a tuning aid to move the car off the line a little quicker. Back in the 60s and 70s, when many of us ran in Super Stock eliminator, this septum modification/addition was trendy. Racers could be seen changing them between rounds at the track, depending on track conditions to get more torque or top end,” stated Hughes.

The Hughes Engines testing should end the question about which manifold to use on a particular engine. The dual-plane will reign supreme as the “King of the Street,” which will result in an engine and vehicle with good manners and is fun to drive, yet will put any single-plane to shame if a little street light action should arise.

A related benefit of the dual-plane manifold is a possibility of better fuel economy, provided you can keep your foot out of the throttle. If the car will only see time at the drag strip, and the engine is a high-rpm mill, then the single-plane design is the winner by far. The choice is yours. What do you want from your engine, and what are you willing to trade-off to get it?

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by