One of the greatest struggles for the owners of automobiles is something we like to call “Modification Remorse.” Modification Remorse affects hot rodders, road racers, and off-roaders alike. No matter what denomination of automotive performance, modifications to vehicles must be made in order to allow vehicles to go faster, corner harder, jump higher, or cover more challenging terrain. Changing stock components to altered or completely different parts can essentially start a butterfly effect for any vehicle.

For example, the owner of a Plymouth Duster decides he wants to be able to rack up faster ET’s at the local drag strip so he purchases a set of drag radial tires. These tires offer dramatically more grip than any tires offered when the Duster was purchased in 1972. As a result, after a number of hard launches, the Duster suffered a broken axle shaft in the rear end. To solve the rearend weakness, a Dana 60 is installed in car. This is where Modification Remorse is likely to kick in; with money being thrown at the car in order to fix the problems now present, the owner will likely have a thought similar to “If only I had just left the car alone.”

Above left: Various parts were collected including the Cherokee donor transmission, transmission control unit, Cherokee electrical connections, Cherokee flywheel and hardware. Pictured here is the AW4 transmission next to the TJ’s stock P231 transfer case. Above right: Removing the stock 32H transmission from the Wrangler is pretty strait forward and can be done in a couple of hours with the help of a friend or two. With the two transmissions side by side the size difference between the two is very obvious.

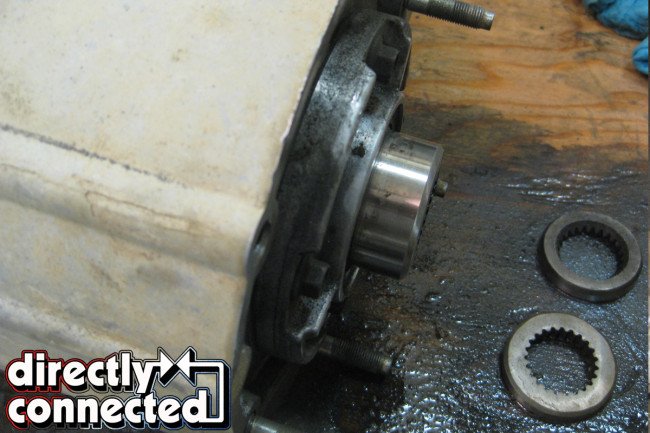

Above left: In order to mate the TJ transfer case with the XJ transmission the output on the transfer case has to be cut down or changed to the shorter Cherokee style. We chose to cut ours down, one person running the angle grinder while another slowly turned the transfer case yoke to turn the input shaft. Above right: After the shaft had been modified we were able to mate the transmission and transfer case before installation into the Jeep.

In the off-road world, “If I had only left the rig alone” is an all too present idea as owners add differential lockers to ill-equipped axles, add engines with more horsepower to neglected transmissions, or add winches and off-road lights to underperforming alternators. But after the brief moments of Modification Remorse pass, vehicles may continue to be modified in order to eliminate weak links and achieve greater performance.

Our 2002 Jeep TJ is no exception to the idea that modifications beget more modifications. The stock Jeep was equipped with 28” tires, the 35” tires later installed on the Jeep meant that axle gear ratios would need to be changed for the Jeep to have any hope of pushing the big rubber. The Jeep would have performed best with an aggressive ratio like 4.88s or even 5.13s, but such aggressive gear ratios would have caused a major issue that hot rodders are all to familiar with.

Above: Next up was modifying our Clayton Offroad crossmember to accommodate the AW4’s 3-inch longer length and different mounting locations. This job was relatively simple with a measuring tape and a square.

Above: Once the shape had been determined lots of gussets were welded in to make it strong enough to mount the skid plate once again.

Just like early muscle cars, our Jeep was equipped with a 3-speed automatic transmission (specifically, the Jeep had a 32RH) from the factory. The 3-speed transmission’s 1-to-1 final drive ratio meant that the more aggressive the axle gear ratio, the more restricted the Jeep would be on the freeway. Our Jeep was equipped with 4.10 gears to try and tackle the large tires, but even with the mild gear ratio our Jeep was forced to cruise the freeway at sub 60 MPH in order to avoid over revving the motor.

Modification Remorse hit us hard as the Jeep became so much less streetable because of our big tires. We were unwilling to give up the large tires (and hurt off-road performance) so it became clear that the transmission would need to be changed for a unit with a higher final drive ratio.

With the problem evident we sought out to find out what transmission would be the proper replacement. The six cylinder Jeep TJ Wranglers were offered with either manual transmissions, the 3-speed automatic that we had, or a later overdrive transmission (the 42RLE). It seamed the 42RLE would be the obvious choice since it had overdrive and was offered in the same model of Jeep, but it became very apparent from research that the 42RLE is a weak transmission, prone to failures of all kinds and really not an ideal choice for our build.

Above left: Once the crossmember had been painted it was ready to hold up the drivetrain once again. Installing the new transmission was pretty start forward. Just make sure the torque converter is fully seated before it is bolted up to the motor. Ask us how we know. Above right: With the drivetrain in its home, drive shaft measurements were taken and sent off to be made. The rear driveshaft is about as short as can be made but angles look good so we are happy.

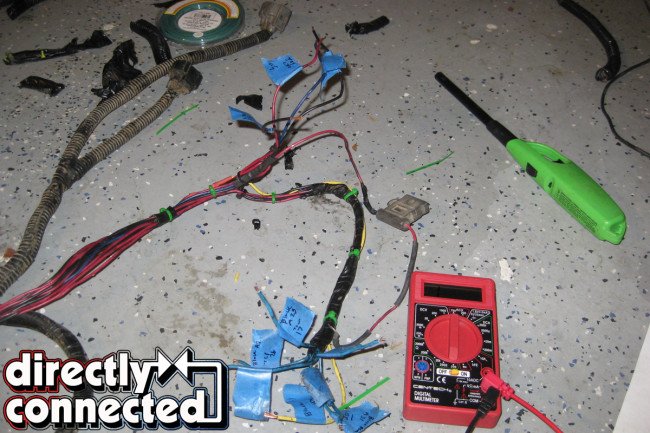

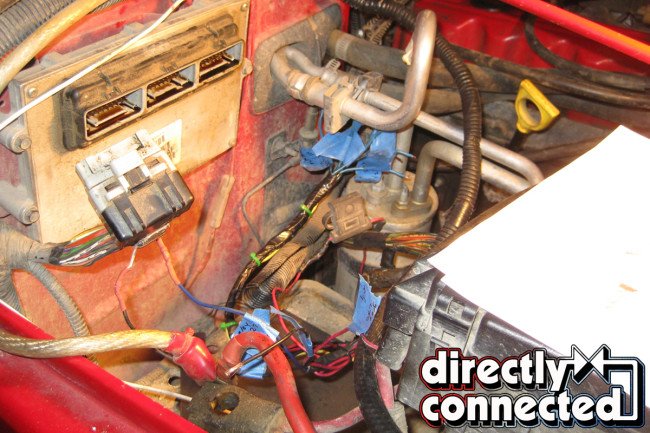

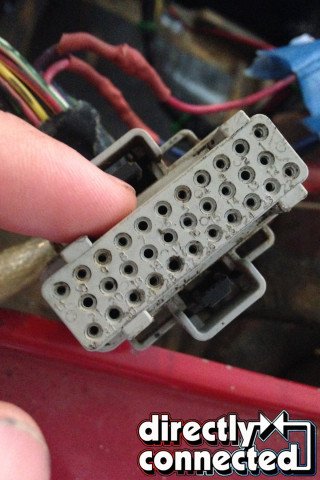

Above left: Once the nuts and bolts were tightened attention was turned to the electrical work. The AW4 is electronically controlled and as such a wiring harness needs to made to connect the Cherokee transmission harness with the TJ’s electronics. Above center and right: Armed with a soldering gun, multimeter, and a razor blade, wires on the stock ECU were exposed so the Cherokee transmission wires could be grafted in.

Manuel transmissions have been standard in the off-road market for decades but again there is a major flaw, stick shifts require the use of very low-geared transfer cases in order for the vehicle to be able to travel slow enough to handle challenging terrain. We knew that the rock trails our Jeep regularly enjoys would ruin a clutch and break drivetrain components in no time without a greater low range. The build budget simply did not have room to purchase an Advanced Adapters Atlas, Stak, or a Teralow transfer case that could provide the needed mega low range.

With all other factory equipped TJ transmissions crossed off our list, things started to look bleak until we stumbled upon some information on a handful of factory equipped manual transmission TJ’s that had later been swamped to the Aisin AW4 transmission found in the Jeep XJ Cherokee. The Aisin AW4 is a primarily Japanese transmission that was equipped in nearly all automatic Jeep Cherokees. The AW4 has long had a reputation as an extremely stout and reliable overdrive transmission amongst Cherokee owners. This transmission seamed like the perfect candidate for our TJ swap.

So far the overdrive transmission swap has been a complete success. The .75-to-1 final drive ratio means our Jeep is capable of cruising over 70 MPH again, and the electronic brain of the AW4 makes for much more responsive shifts than the old 3-speed ever managed. We only wish we had done the swap years ago. While we may have had Modification Remorse for our big tires we have had nothing but good results from the new transmission and we plan to keep on modifying the Jeep from here on out to get closer to the goal of a King of the Hammers ready, daily driving TJ.

Above left: A multimeter was used to check wires for continuity and then pin-test the numbered wires on the factory ECU. Above center: Once the electronics were mocked up, transmission cooler lines were incorporated into the Wrangler’s stock cooling system using hard line from a Cherokee that was bent to meet up with the frame rail. Above right: After several miles of road testing to get us comfortable with the transmission cooling lines and wiring, the Clayton Offroad skid plate was reinstalled and we headed off to see this transmission in action.

This is a great write up. Been considering the change from the 6 speed rubicon everyone wanted to the 42RLE I should have got. They say that conversion is very hard due to the electronics. I have a 2006 Rubicon. Wonder if the AW4 would work in it or will electronics get in the way?

Good question! Please email our off-road editor at kyle.cunliffe@shawgroupmedia.com

Hey Matt,

So far as I know nobody has done an aw4 swap from your model Rubicon. The three speed auto I had was the last of the mechanically controlled automatic transmissions, Other guys swap from manual transmissions to the AW4 which of coarse manual transmissions are also mechanically controlled. SO in that respect you should be able to pull it off, The only unknown is what electrical differences your later model ecu will have compared the my early model (98-02). Check out Stu Olsen’s web site, it’s where I got the wiring info for mine. Now with the aw4 swap there are also a number of different headaches to take care off, will need to build a new crossmember, tranny lines, you will need a new radiator for cooling purposes unless your radiator has the cooling ports that are just blocked off. More than likely it will be far easier for you to just swap in the 42RLE because you can get all TJ factory parts to pull it off. The strength disadvantage will be the only downside to the 42RLE to the AW4.

Thanks for the reply!

Kyle Cunliffe

Off-road Truck editor

Hello,

I appreciate the article. It opened up a new method of modifying the AW4 to my wrangler. Do I need to do any wiring modifications if I am swapping the engine, transmission and computers? I can salvage anything I need from my donor 2000 4.0 L Cherokee Sport. Thanks!

I am in putting a 2001 AW4 into my 98 wrangler- got all the mechanical work done but I am struggling on the wiring Any one done this and can give some pointers or help. I have the TCM and full wiring harness to the new trani. Just not very good with this part. Thanks

Iam in in the middle of replacing the 3 speed auto transmission in my98 tj With an AW4. I could use some help on the wiring. I have the transmission module for the aw4.