In the 1980s, CliffsNotes was all the rage to get through high school literature classes. Whether it was a work of Shakespeare, Orwell, or Dickens, CliffsNotes covered it. The CliffsNotes provided a condensed version of the stories explained by teachers and professors, which, in turn, eased the headaches of deciphering the hidden meanings and undertones of the work.

Armed with CliffsNotes, students’ cumbersome reading was reduced to a manageable volume, and exam test scores often rose. Today, CliffsNotes still exists, but unlike the booklets of the 1980s, the company has an extensive website with highly organized information about thousands of academic books.

At PRI, Mopar Connection Magazine had the privilege of speaking with Callies Performance Products’ CEO Heath Norton. He shared that while the Callies website is due for an update in 2025, they have a temporary solution. Until the revision, Norton has provided us with a Callies version of CliffsNotes in the form of information download sheets. The resource is a convenient and comprehensive guide for those interested in high-performance engine building.

For those serious about making big horsepower, the download sheets contain all the practical details on Callies, Energy, and Compstar’s blocks, cranks, rods, camshafts, etc. For fun, we decided to build an engine on paper. We have a breakdown of specific components and supporting parts for a naturally aspirated Gen III Hemi build.

Formulating an engine combination is a highly consultative process. Before contacting the Callies technical department, please have the following information: desired cubic-inch displacement, preferred compression ratio, the cylinder head cubic centimeters (CCs) volume of the combustion chambers, final bore sizing, and deck height.

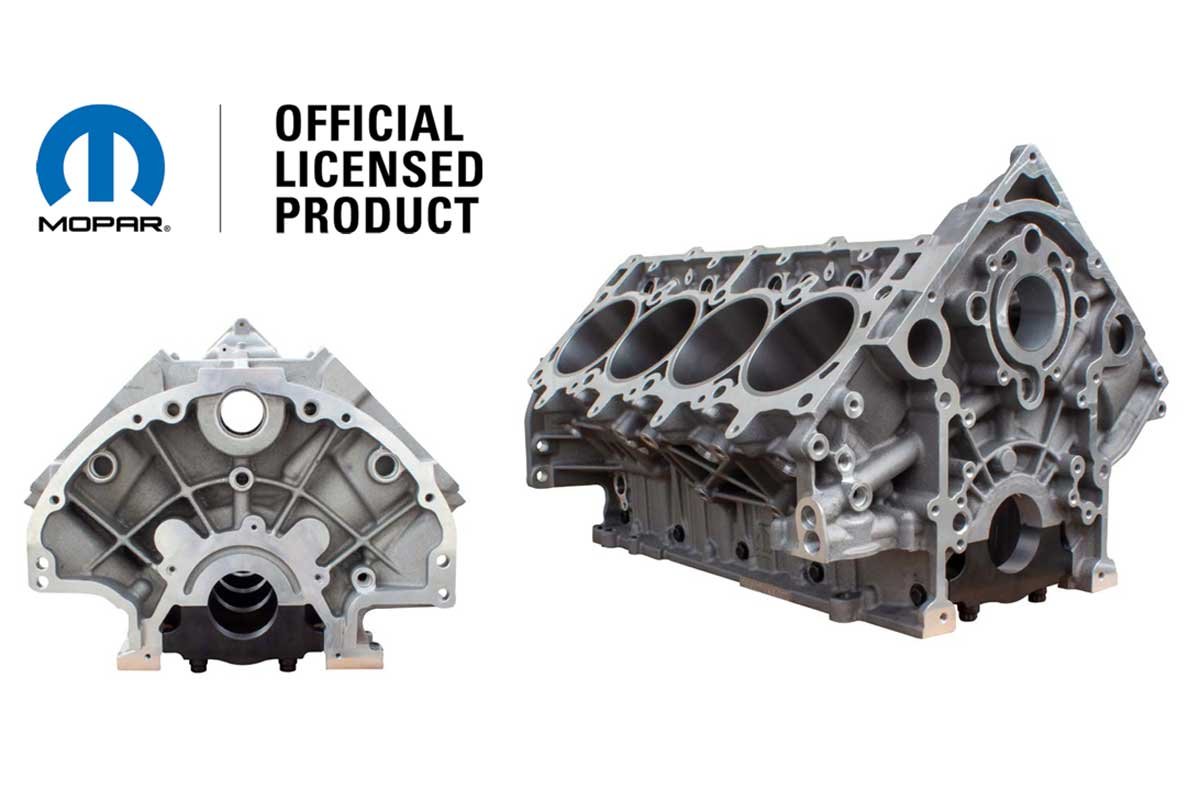

We will start with the foundation of the engine build – the block options. Depending on your budget and the engine’s intended use, Callies offers a thrilling array of four engine block choices. These include two Gen III cast aluminum Mopar blocks, Hellephant and Dragpak, each with unique features, and two cast iron versions of the Gen III Hemi block.

The aluminum Hellephant block includes:

• A deck height of 9.25-inches (stock is 9.284-inches)

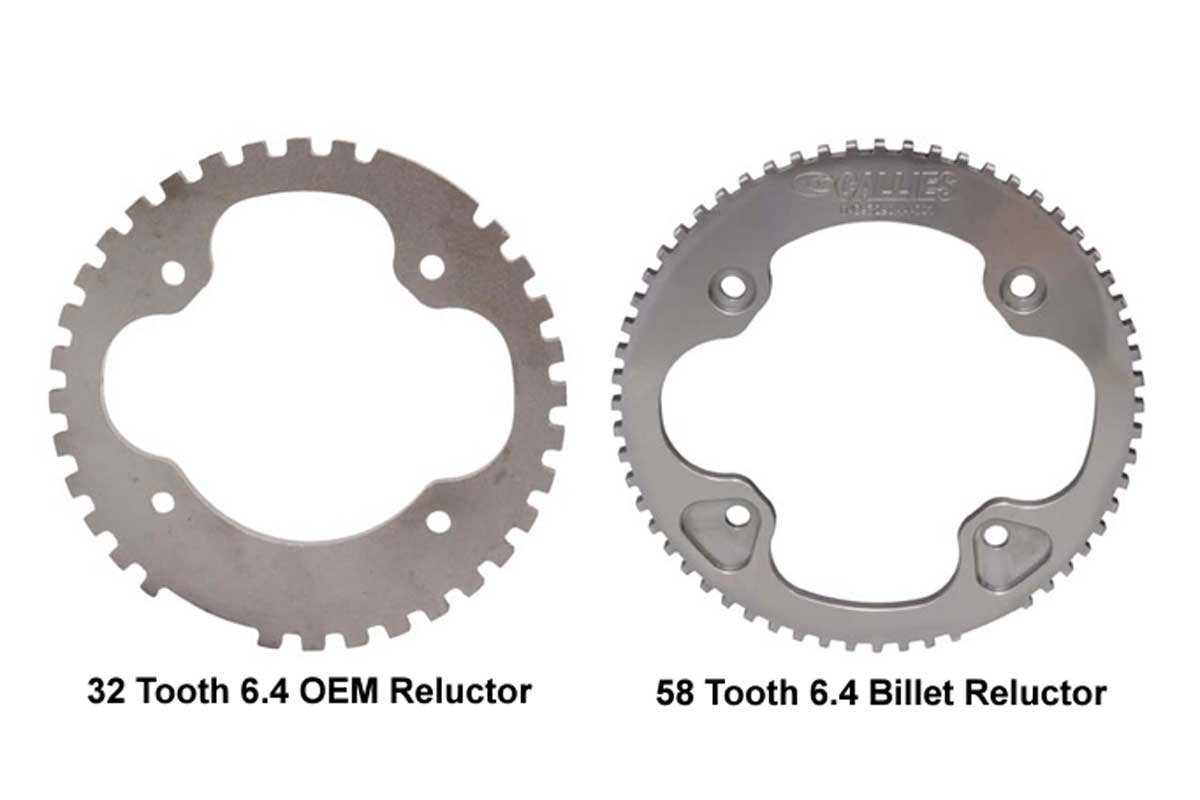

• Utilizes a 6.2/6.4-liter timing drive

• Provisions for VCT solenoid

• A standard lifter pattern with 0.842-inch bores

• Utilizes a standard cam bore, bearings installed

• Delivered with 4.120-inch bores – allows for finish honing of 4.125 inches

• 4140 q/t billet main caps

• 4 bolt M1 & M5, 6 bolt M2-M4

• M12 head studs available

The aluminum Dragpak block includes:

• A deck height of 9.25 inches

• 6.1-liter timing drive

• No VCT solenoid provision

• 0.937-inch keyway lifter bushings that require a finish hone

• 60mm RB cam bore, bearings not included

• Delivered with 4.120-inch bores – allows for finish honing of 4.125 inches

• 4140 q/t billet main caps

• 4 bolt M1 & M5, 6 bolt M2-M4

• ½-inch head studs available

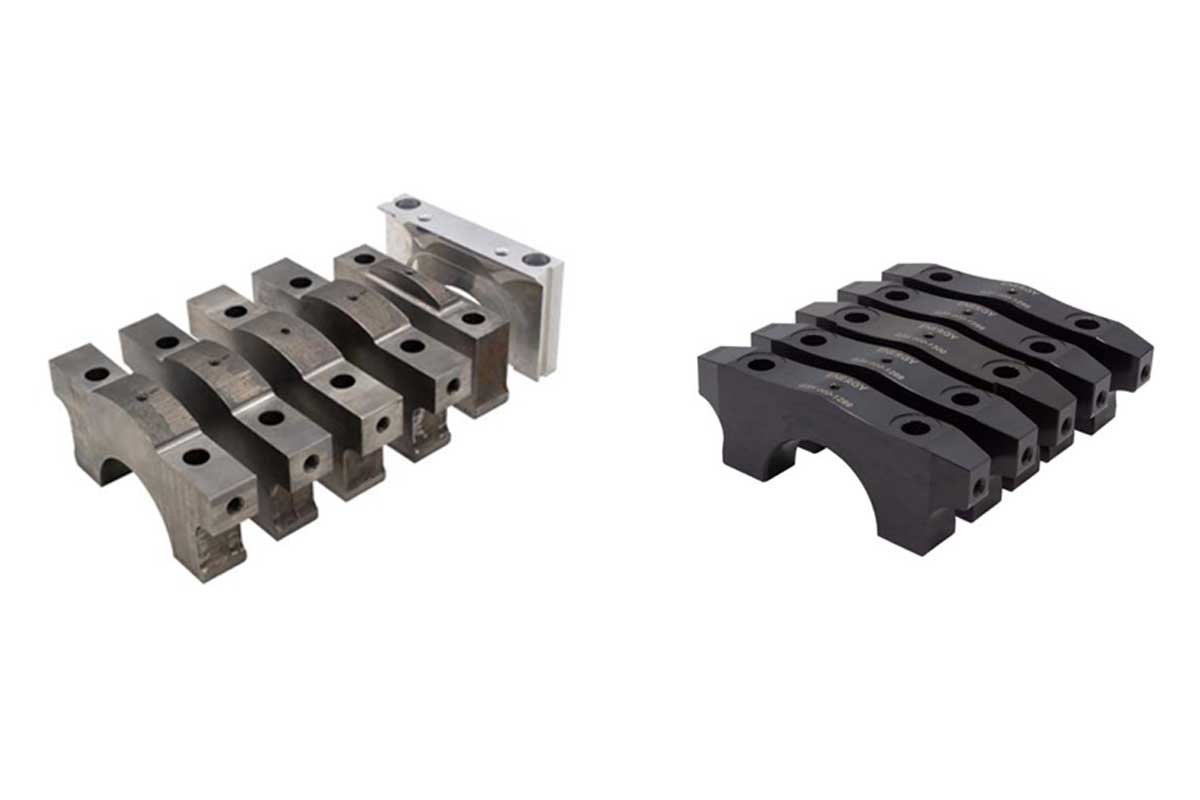

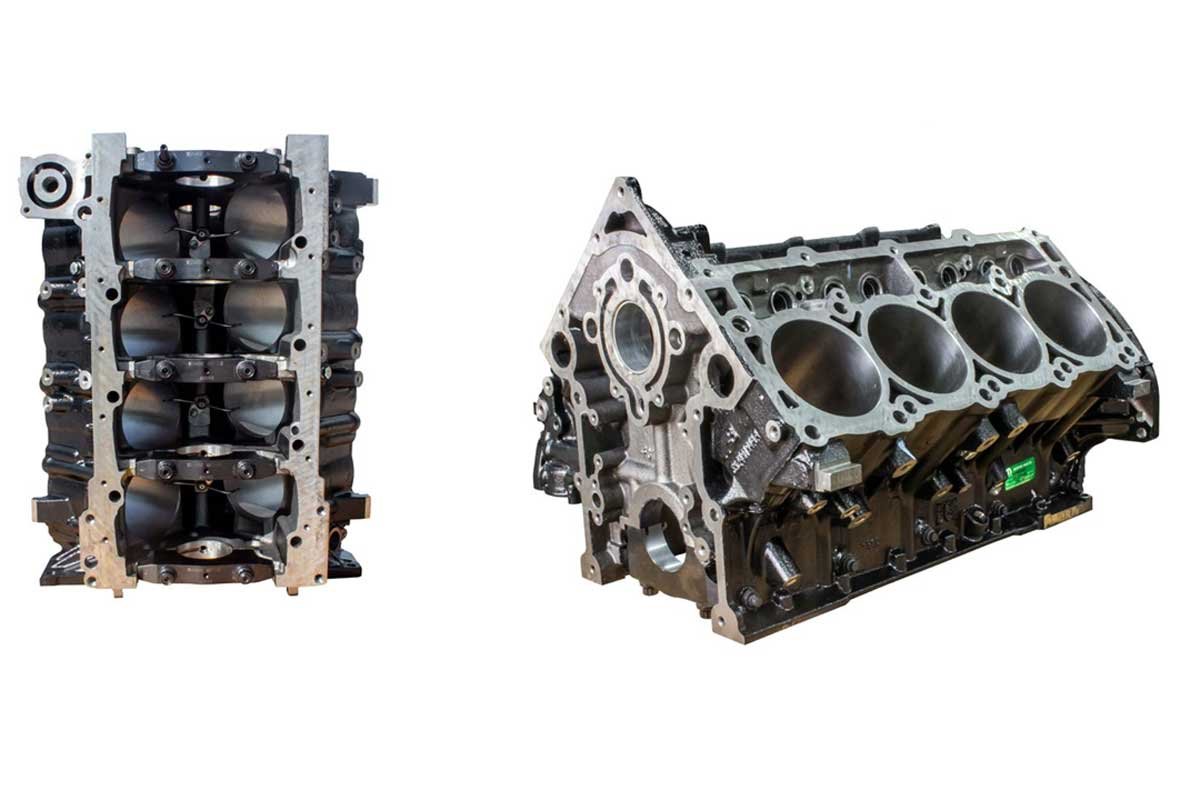

Another avenue is a choice of two cast iron blocks: the Gen III Hemi 6.4-liter cast iron “BGE” bare block (Part No. 05045475AG) or the 6.2-liter bare block (Part No. 68166434AD). Both are available with OptiTorque main stud kits, main studs and Energy main billet caps, or studs, caps, and line honing.

Moving to the rotating assembly, we can use a Callies 8 Counterweight Magnum or a Compstar Crankshaft. The Magnum is a premium option with excellent strength for high-RPM applications, but Compstar is a more budget-friendly yet exceptionally durable choice. In either case, stroke options are 3.800 inches, resulting in a 392 cubic inch displacement, or a longer stroke of 4.000, 4.050, or 4.200 inches for stroker applications.

For the connecting rods, Callies offers the Mopar Ultra Enforcer I-Beam, rated at 2000 horsepower (hp), which may be overkill for an enthusiast’s needs. Moving down to the Compstar Xtreme is a good choice, rated at a maximum of 1800 hp. Lastly, there is the Compstar H-Beam, rated at 1000 hp.

The rod offerings have lengths varying from 6.000 to 6.250 inches and rod journal sizes from 2.100 to 2.125 inches. The I-beam designs are ideal for high-stress applications and offer superior strength. The H-beam rods are lightweight and suitable for high RPMs while remaining a cost-effective alternative.

Callies recommends many different piston manufacturers. For a naturally aspirated engine, a matched set of forged pistons from Mahle, JE, Wiseco, etc., with a complementary ring package in a compression ratio range of 10.5:1 to 12:5:1 will make excellent power on high-octane pump gas or race gasoline. Due to the vast range of parts and individual needs, no two Callies rotating assemblies are the same.

The camshaft choice is a crucial decision in our engine-building journey. If we aimed for a street-only engine, we could select from Callies’ in-house, fully finished machined, and heat-treated Valve Train Group (VTG) series of camshafts. A camshaft with a lift of around 0.600 inches (with 1.6:1 rockers), 230-240° duration at 0.050-inch lift, and 110-114° LSA would be ideal. The VTG 141 camshaft series offers several great options, each with its unique benefits, depending on the desired usage of the engine.

With the camshaft selected, a quality set of high-performance dual valve springs (e.g., Comp Cams, PSI) rated for high lift should be chosen. Hardened pushrods (e.g., Smith Brothers) are also desired to withstand the increased stress. Callies have Mopar intake and exhaust rocker arm assemblies.

A Holley Sniper EFI or a Mopar Performance high-rise intake provides excellent airflow and can be matched with a large (90mm-105mm) throttle body to feed the Hemi at higher RPMs. A selection of 42 lb/hr fuel injectors will meet the engine’s needs and provide room to grow if more performance is desired. A quality fuel pump from Aeromotive or Holley will meet the target performance numbers for most applications.

A set of MSD or Mopar high-performance coils can manage the spark needs of the Hemi. The exhaust gases will benefit from long-tube headers from TTI or Hooker. Three-inch pipes should be employed from the header collectors to the tailpipes. A quality pair of catalytic converters and mufflers will minimize the exhaust backpressure.

After the engine parts are machined (as needed) and the engine is assembled, tuning will be necessary. Dyno tuning will likely be required to maximize the engine’s performance. The rough estimated cost for parts, machining, assembly, installation, and dyno-tuning for a DIYer will range between $10,000 and $15,000+. If a professional oversees the work, the estimated cost will increase to $15,000 and $20,000+.

Even if a complete engine build is not in the budget, Callies‘ information download sheets provide critical data about all the parts and pieces you can purchase for your project. Take advantage of Callies’ “CliffsNotes” while they are still available.