There is an ongoing debate between the Mopar purists that want to retain the factory torsion bar suspension and those that want to upgrade to the latest, most modern coil-over front suspension. While the discussion may continue to rage, QA1 has the suspension components and complete systems that meet the needs of the torsion bar devotees and the coil-over enthusiasts.

Above Left: Chrysler introduced the torsion bar front suspension in 1957. QA1 updated the suspension components to increase the rigidity and allow greater adjustability. Above Right: To optimize the front end of the muscle-car era Mopars, QA1 developed an updated coil-over front suspension. The coil-over suspension utilizes all the latest technology, exceeding the factory design and performance.

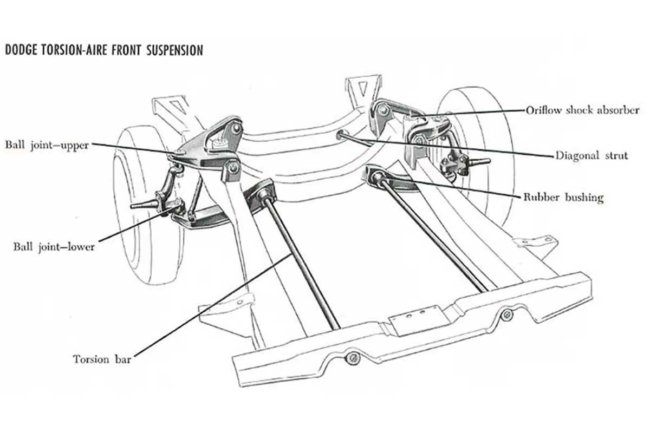

The torsion-bar front suspension debuted in 1957 across all the Chrysler Corporation models. Chrysler advertised the suspension for some years under the trademark name “Torsion-Aire.” After a layout reengineering in 1976 on the F-body platform, Chrysler would continue using the torsion bars on the rear-wheel-drive layouts until the end of production of the 1989 M-bodies. However, Chrysler did use a front torsion bar system on some generations of the Dodge Dakota and Durango.

Above Left: The original longitudinal torsion bar suspension was used through the 1976 model year. Above Right: In 1977, Chrysler redesigned the suspension to a transverse torsion bar design, which was used until the end of the RWD car platform.

Early claims about the advantages of the Torsion-Aire suspension included decreased high-speed float, reduced harshness from road impact, and lessened road noise. Moreover, the torsion bars limited body roll and nose dive, increased ride balance, provided added directional stability and cornering ability, and lastly, there were fewer lubrication points.

Additional benefits of the torsion bars included ease of ride height adjustment and uncomplicated torsion bar swap procedures to change the spring rate. All outstanding claims in the 1950s compared to the era’s competition. However, the 65-year-old torsion bar technology is quite lacking compared to a modern vehicle.

Above Left: Bias-ply tires were factory installed for years on all vehicles. Most manufacturers recommended positive camber (top of the tire tilted outward as viewed from the front). Above Right: With the advent of radial tires, the manufacturers moved to negative camber (top of the tire tilted inward as viewed from the front) to take advantage of the tire design and keep it planted during cornering. (Hunter Engineering Photos)

There were a few disadvantages of the torsion bars right out of the gate. Unlike coil springs, the torsion bars could not provide a progressive spring rate. In addition, the longitudinal torsion bars (1957-1976) extended under the passenger compartment, which reduced interior space due to a raised floor. The longitudinal torsion bars also limited the exhaust routing from the engine bay.

Above Left: Because many of the older Mopars did not have power steering but were substantially heavy, negative caster (tilt of the steering axis forward compared to vertical as viewed from the side) allowed for ease of steering. Above Right: As power steering became more prominent, manufacturers began moving to positive caster (tilt of the steering axis rearward compared to vertical as viewed from the side) to promote directional stability and steering wheel returnability. (Hunter Engineering Photos)

The transverse torsion bars (1976-1989) eliminated the exhaust restrictions; however, the length of the bars was determined by the track width of the front of the vehicle. Additionally, the transverse units sagged more quickly and, in many instances, bent the k-member. Furthermore, both torsion bar suspension designs had compromises to obtain a cost-effective, easily serviceable suspension that would last thousands of miles of street use.

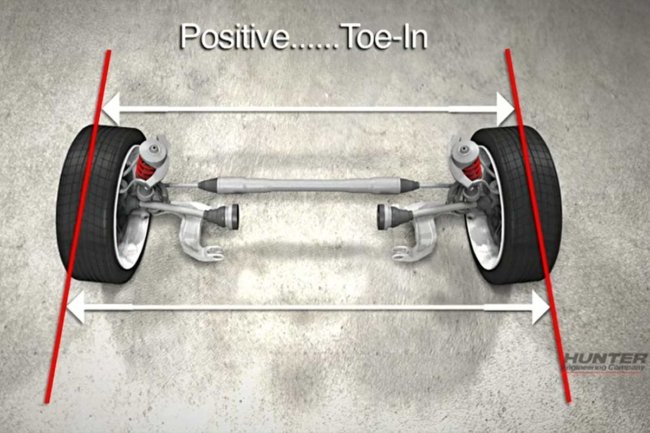

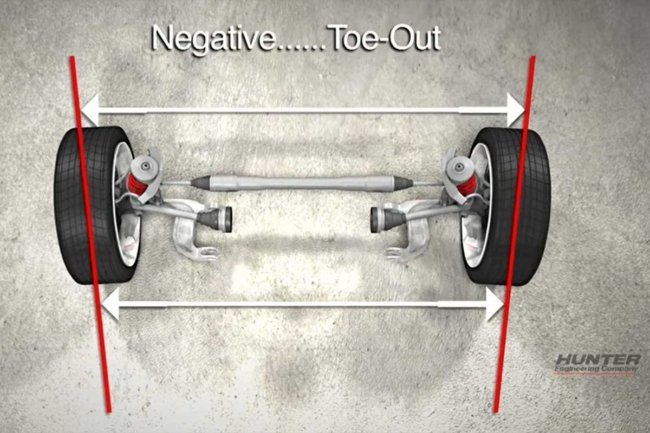

Above Left: Nearly every manufacturer recommends a small amount of toe-in (the distance between the front of the front tires is less than the distance between the rear of the front tires). (Hunter Engineering Photo) Above Center: Occasionally, there is a toe-out (the distance between the front of the front tires is greater than the distance between the rear of the front tires) recommendation for performance road course racing. (Hunter Engineering Photo) Above Right: Bump steer is a condition that occurs when the front toe changes due to bumps in the road without driver steering input. Therefore, it is imperative to line up the ball joints and the outer tie rod end (steering axis) and align the inner control arms and inner tie rod end (line 2) to keep the movement of the components in the same arc to minimize bump steer.

Suppose you are devoted to the tried-and-true longitudinal torsion bar suspension. In that case, QA1 offers a catalog full of updated components to increase the hardiness of the suspension while reducing the overall weight of the front end.

For example, we added tubular upper control arms (UCA) to our ’69 Dart. Eventually, we added tubular lower control arms (LCA) and dynamic strut rods. Finally, we made a significant transformation by installing an all-tubular QA1 k-member under the 340.

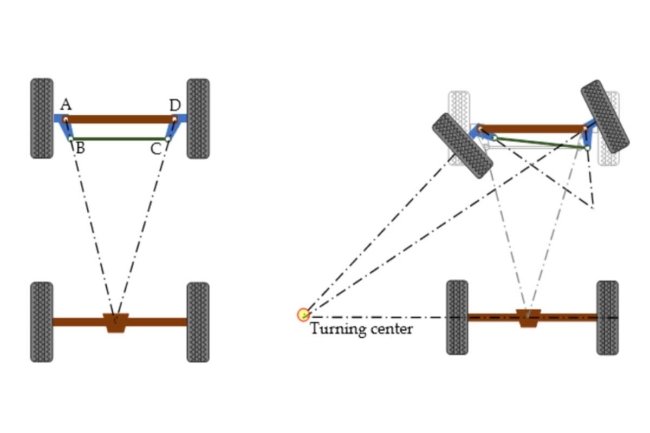

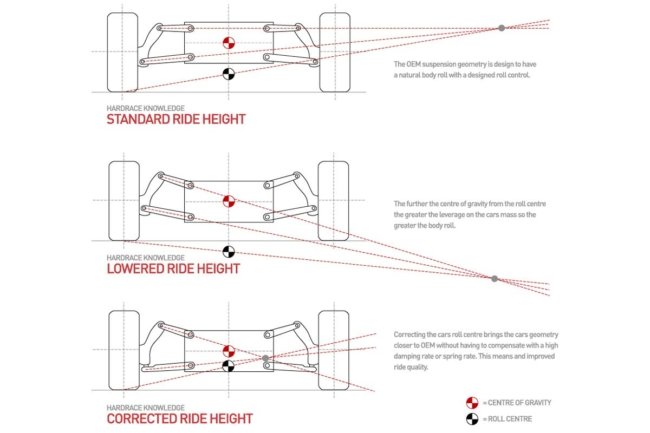

Above Left: When a line is drawn through the lower ball joint and outer tie rod end on each side of the car, they should intersect at the rear differential. The steering geometry of the intersecting lines is known as Ackermann angle. The Ackermann angle causes the wheels to toe out when the steering wheel is turned. Some alignment shops and dealerships refer to Ackerman as toe-out on turns. Above Right: A roll center is a theoretical point around which the chassis rolls and is determined by the suspension’s design. The roll center can be moved by changing the angle of the control arms.

The installation of all the QA1 parts reduced the weight of the front end of the Dart significantly while substantially increasing the strength and rigidity. QA1 recommends adjusting the dynamic strut rods to the stock length and using the UCA eccentrics to set the caster and camber angles. It is not advisable to adjust the caster with the strut rod because it can pull on the LCA, resulting in binding at the torsion bar and pivot.

Above Left: QA1 has Drag Kits for the longitudinal torsion bar cars. Each kit strengthens the front end while reducing the weight of the front suspension. The upper control arms have additional positive caster built into them. The dynamic strut rods eliminate the rubber factory bushings. Above Right: For the road course Mopars, QA1 has developed its Handling Kits. The kits come with a sway bar. Even with quality QA1 components installed, the factory roll center, Ackermann angle, and bump steer remain the compromise engineered into the vehicle decades ago.

The most significant benefit of the dynamic strut rods is the elimination of the OE rubber bushings that deflect under braking and allow caster and toe change. The QA1 dynamic strut rods are designed with rod ends that do not deflect like the OE rubber bushings.

Because the QA1 UCAs have positive caster built into them, we quickly adjusted our Dart’s caster to +4.5° (LF) and +4.2° (RF) at each front wheel. A substantial positive caster promotes better straight-line stability and steering wheel returnability. QA1 recommends a caster angle of +3° to +5° on the torsion bar suspension.

Above: Our ’69 Dart utilizes the QA1 Drag Kit components. All the components fit without the need for modification. The new QA1 components dropped the front-end weight by more than 25 pounds. The front end works great at the drag strip. With the “freer” moving suspension and reduced weight, we dropped the elapsed quarter-mile times by a consistent .05 seconds.

However, even with all the quality QA1 parts, we are still constrained by the factory mounting locations of the control arms and tie rod ends. Thus, the factory design compromises are still found in the suspension. The roll center is about a foot above the ground, and there are bump steer concerns as the front toe changes with suspension jounces and rebounds. Nevertheless, we have been pleased with the performance of all our QA1 components, even with the torsion bar suspension.

Above: The QA1 coil-over kit comes with a tubular k-member, reducing weight and making room for big-tube headers. The tubular control arms provide modern geometry for improved handling and drivability. A powered rack-and-pinion steering delivers a modern car feel. In addition, the k-member has modular engine mounts that accommodate several different engines.

How could a Gerst-designed QA1 coil-over front suspension surpass the torsion bar system, even one updated with QA1 components? First, the QA1 engineers started with a blank sheet when designing the coil-over suspension. Then, they created a modern suspension based upon the nearly seven decades of technological advancement since the introduction of torsion bars on Chrysler products.

The preferred factory specs for our manual steering Dart were camber 0.5° (Left) 0.25° (Right), caster -1° to 0°, and a 1/8-inch toe-in. The days of bias-ply tires have passed, so no longer will positive camber settings be used. As described earlier, the torsion bar suspension with dynamic strut rods achieved +4° of caster, and we could adjust the camber into a negative setting as desired.

With the coil-over suspension, the caster can be increased to +6°. In addition, the QA1 coil-over suspension allows negative camber, optimizing the cornering adhesion of today’s high-quality, wider radial tire to the road surface.

Above Left: To adjust bump steer, QA1 uses Endura Series Chromoly rod ends with spacers to change the outer tie rod’s position to follow the lower and upper ball joint arc path. Above Right: The QA1 coil-over front end eliminates the torsion bars. As a result, there is plenty of space for exhaust and the oil pan without the torsion bars or the bulky k-member.

To achieve the modern suspension responsiveness, QA1 Fitment Specialist Damien Brase explained, “The factory roll center at stock height is 12-inches above the ground while the QA1 coil-over design puts the roll center at about 2 ½-inches. The LCA mounting position, use of Mustang II based spindles, and 1” taller than stock upper ball joints all contribute to the change.”

A rack-and-pinion is included with the system when switching to a QA1 coil-over suspension. Not only will this allow for additional lower engine bay space (no pitman or idler arms and no center link), but it will provide outstanding steering performance. A thirty-plus-year-old steering box, even when new, would never outperform a quality rack-and-pinion setup.

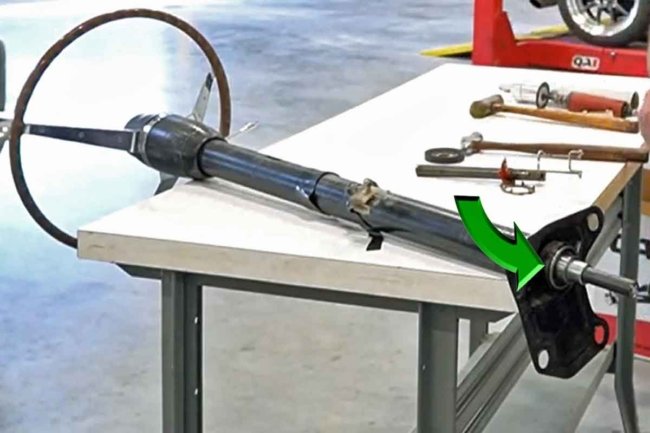

Above Left: Mustang II-style spindles offer a wide range of brake options. Wilwood brake configurations are available from QA1. Above Right: The factory steering shaft must be shortened, and a bearing support (green arrow) must be pressed (carefully tapped) into the lower column. A U-joint and shaft must be welded to the factory shaft to attach the factory steering shaft to the rack-and-pinion. The only welding for the entire installation is the steering shaft.

Brase shared, “The Mustang II-based spindles are modified with custom steering arms to correct the Ackerman angle (toe-out on turns) with the front steer rack and pinion. Lastly, the outer tie rod ends use QA1 Endura Series Chromoly rod ends with spacers allowing bump steer corrections to be made.”

The spring rate can be dialed in with a coil-over suspension to achieve the best performance and compliance. Adding QA1 single- or double-adjustable shocks with the springs allows for fine-tuning of the jounce and rebound cycles of the suspension. Whether adjusting or swapping a coil spring, the task is straightforward—no need to loosen control arms or fight with seized torsion bars.

Above: More room, lighter weight, and updated geometric angles provide a suspension as modern as a late-model vehicle.

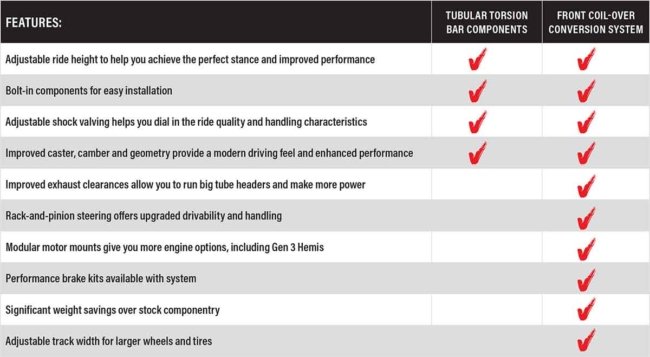

Are you ready to upgrade to a coil-over suspension yet? Well, the list and the chart below summarize the benefits to sway your opinion:

- The coil-over k-member is free from the constantly in-the-way torsion bars. No torsion bars mean reduced built-in engineered compromises or fitment dents in the headers.

- The k-member is designed with modular mounts for more engine options, including the Gen3 Hemi.

- The track width is adjustable, accommodating larger tires and wheels that fit in the factory fender openings.

- Don’t forget about the substantial weight savings at the front of the vehicle.

When it comes time to order a coil-over suspension, the options are boundless. QA1 offers the “Street Performance” or “Drag Racing” front suspensions. Either suspension kit has further options for ride height, shock valving, sway bar, engine mounts, and disc brakes, so take some time to decide.

Above: QA1 lists the benefits of its torsion bar upgrade components, which significantly improves the 65-year-old technology. However, the coil-over design takes a blank sheet approach, resulting in an extensive list of engineered benefits and improvements.

For more information, contact the helpful QA1 representatives for their insightful knowledge. Whether the factory torsion bar suspension with QA1 components fits your build or the modern Gerst-designed QA1 coil-over suspension is a better fit, picking QA1 products will place you at the front of the pack.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by