For many Mopar lovers, an engine swap is considered old hat. However, quite a few “newbies” are joining the Mopar family, which is excellent. So, this tech article should help them get some “cheap” horsepower from a 5.9-liter Magnum. It’s not what many would envision when you say “late model engine swap” but it’s a pretty easy one to do.

Redline Gauge Works‘ head honcho Shannon Hudson came to Mopar Connection Magazine a couple of years ago asking if we’d be interested in following along with Shannon’s son, Talon as he build his first classic Mopar, a super clean B3 Ice Blue 1968 Coronet 440.

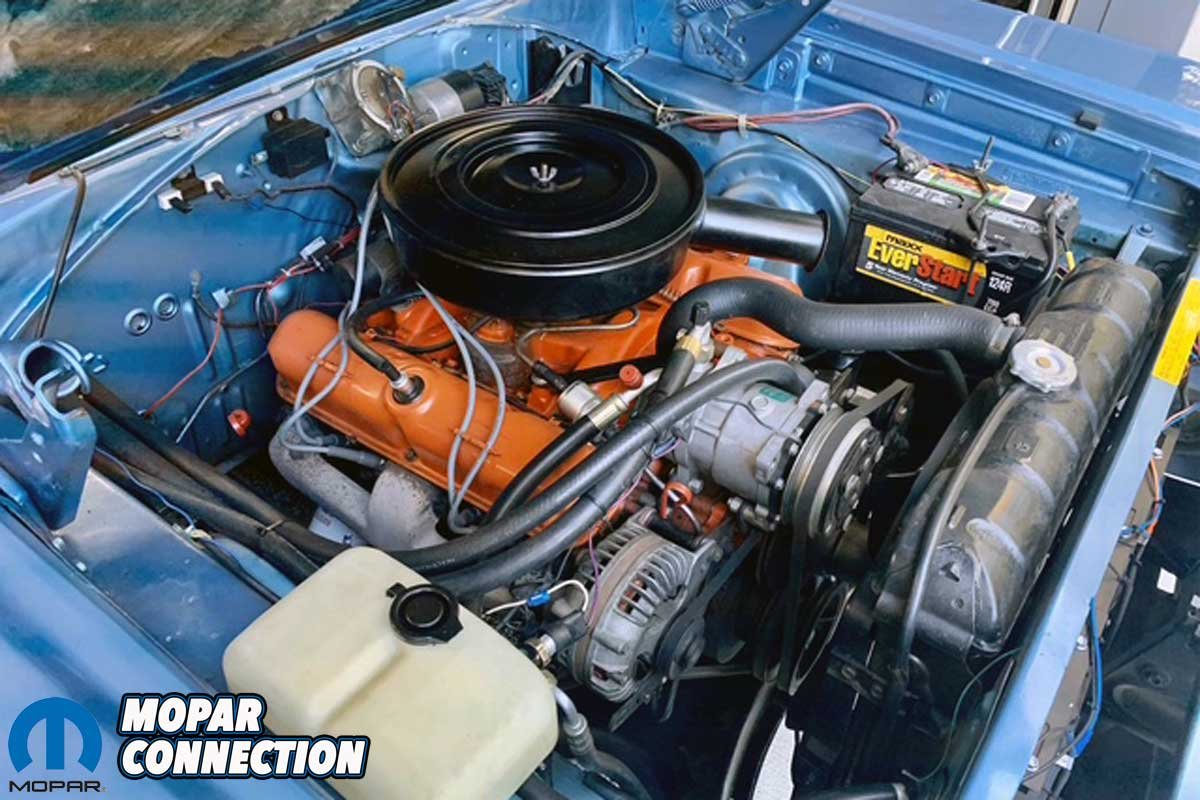

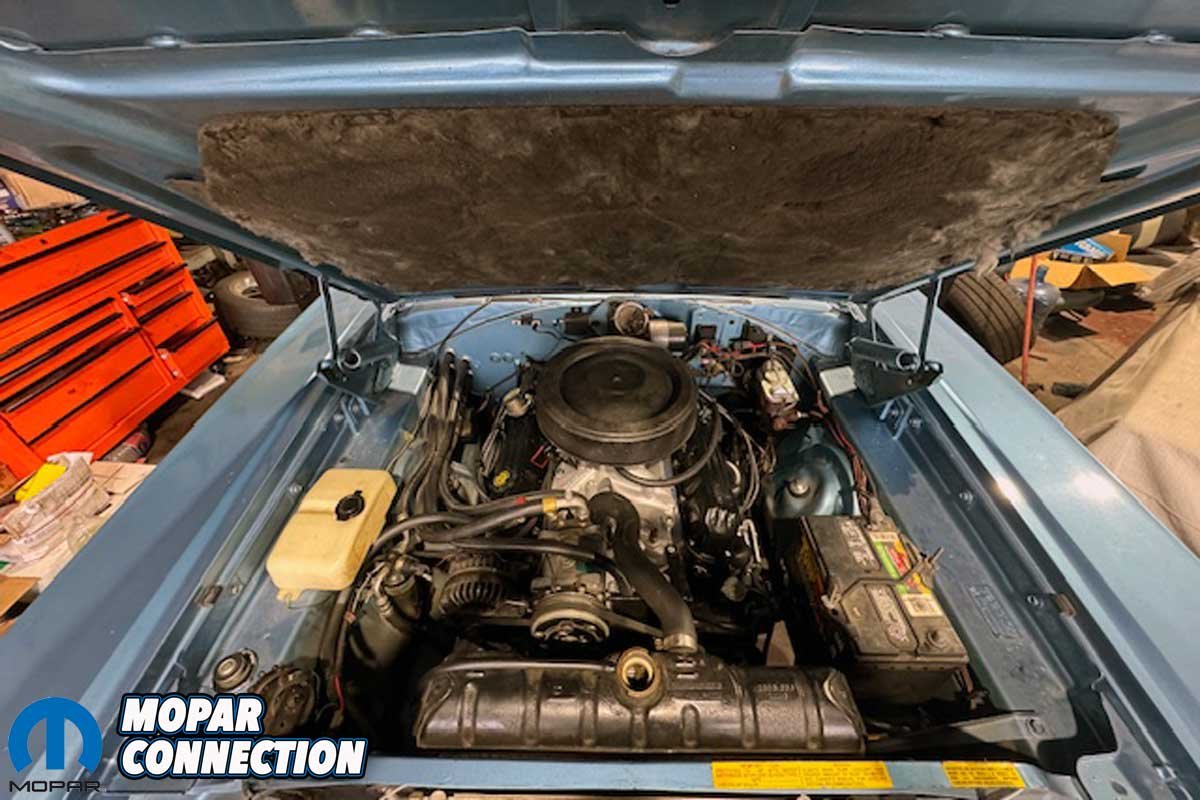

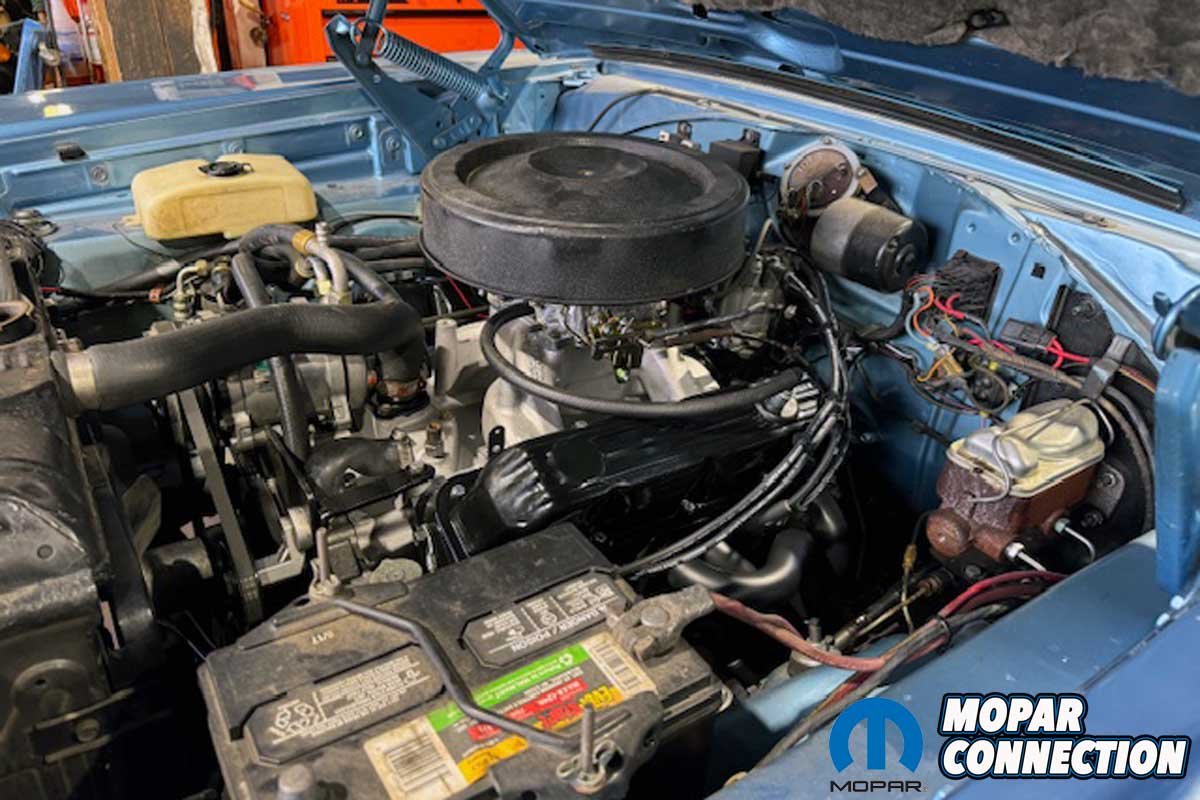

Above: The stock 318 two-barrel engine did a commendable job for decades, but a single event at a traffic light with a Nissan quickly ended its time under the hood.

Some may have read about this “More Door” Coronet featured in MCM a few years back when we did the Master Power disc brake conversion as a father-son project. Since then, he has enjoyed the Coronet until an embarrassing event occurred at a stop light…

A kid in a Nissan Versa challenged Talon to some street action. Talon’s 1968 Dodge Coronet, powered by a two-barrel 318, was embarrassingly outpaced by the Nissan. This incident sparked a need for change. After a discussion with MCM’s editor Kevin Shaw, we decided on a 5.7 Hemi swap to boost the Coronet’s performance.

Above Left: We took the Coronet to Fontana Motorsports to handle the engine swap. Above Right: Just like the factory, the techs at Fontana Motorsports removed the 318 from the underside of the chassis.

Initially, the 5.7 Hemi for the swap seemed like a great idea, but the associated costs made it impractical. However, we had a 5.9-liter Magnum from a ’97 Ram in our shop, which we decided to use. The engine was in good condition, having been part of a 160k-mile truck that had been parted out.

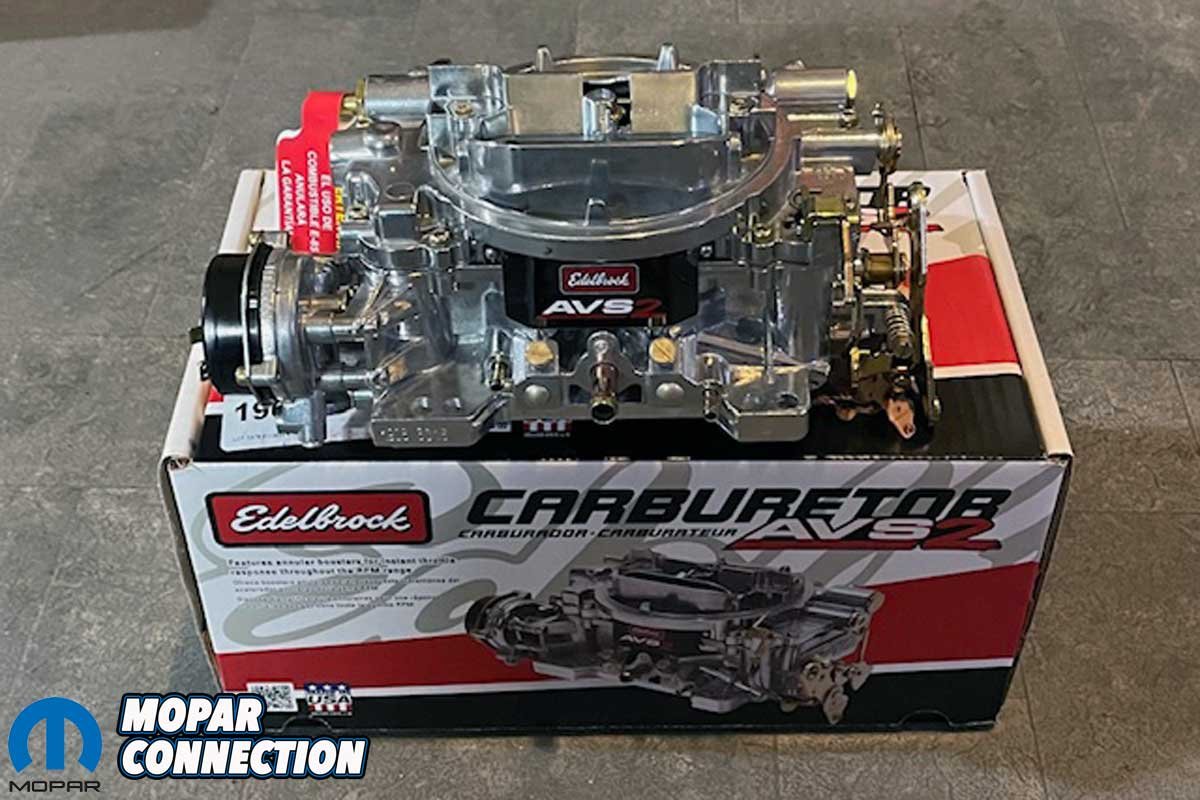

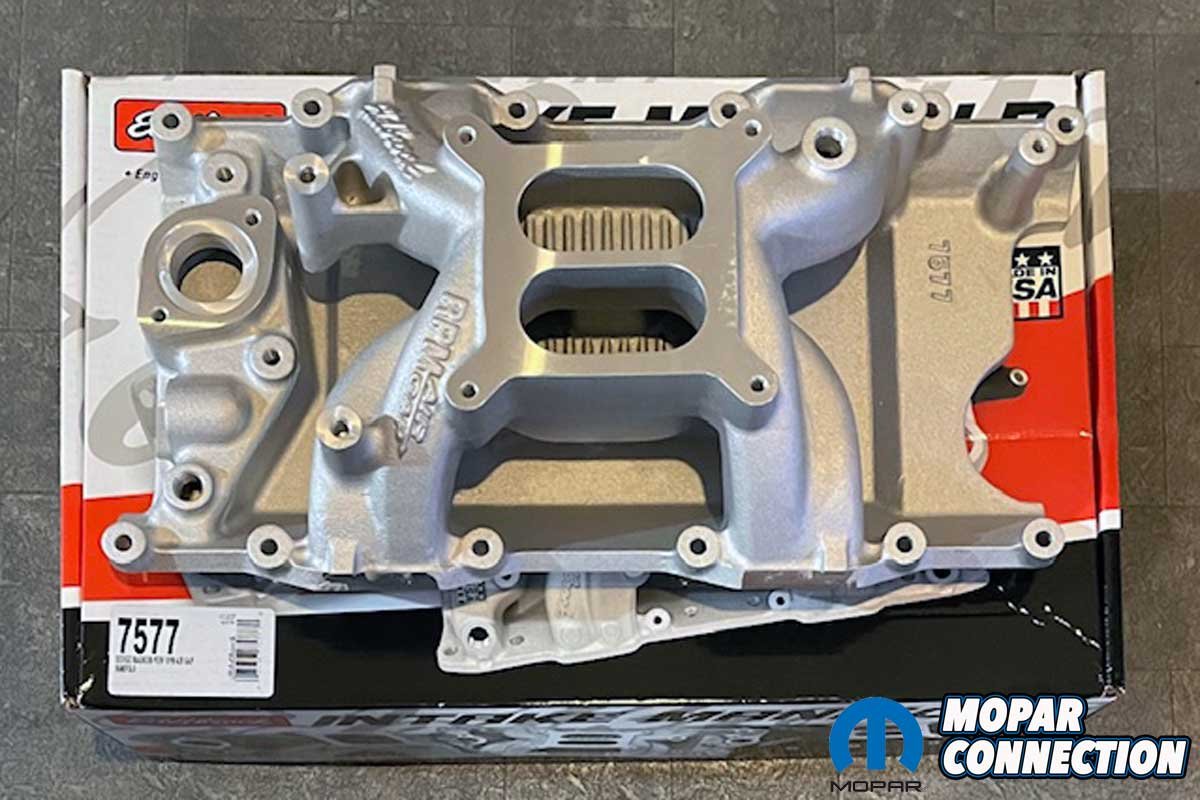

We contacted local Mopar racer Justin Crosby at BBJ Racing in Lancaster, CA, to discuss a few low dollar build options. He recommended a simple but proven combo that included a Comp Cams Mutha Thumpr roller cam (PT# 20-601-9) and springs (PT# 26986-16), an Edelbrock Air Gap intake (PT# ELD-7577), an Edelbrock 650 AVS 2 carburetor (PT# EDL-1906), and a pair of small tube headers.

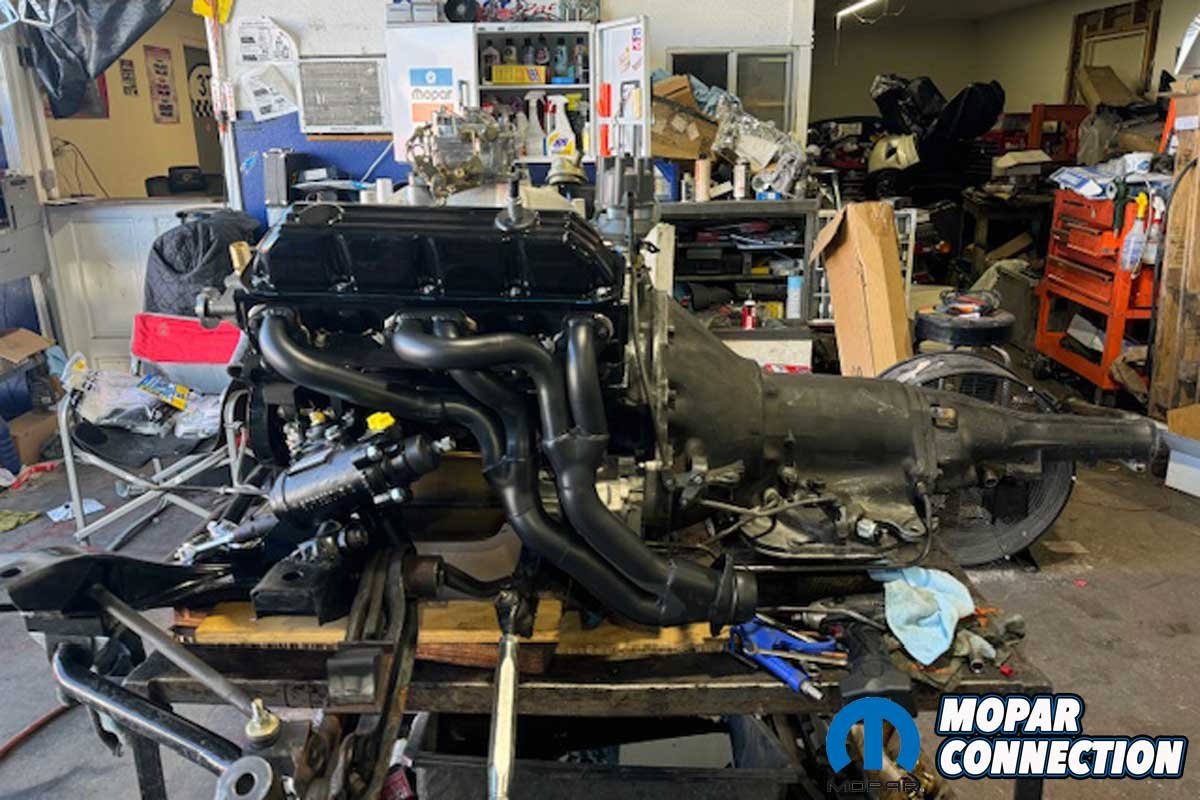

Above Left: Our original plan was to swap a 5.7-liter Hemi into the Coronet, but we had a 160k-mile 5.9-liter Magnum from a Ram on an engine stand in the shop. It would be pressed into service to regain the Coronet’s street cred. Above Right: The factory throttle body, beer keg manifold, and injectors would not be reinstalled on the engine. Therefore, we set them aside for another project.

The engine build plan included reusing the stock rotating assembly and cylinder heads with new valve springs. A Hughes fuel pump eccentric attached to the Comp Cams camshaft would actuate a new mechanical fuel pump.

A new Comp Cams timing chain (Part No. 2103CPG), LA series front timing cover, and a new water pump would be installed. We planned to add a new oil pump and pan that fits around the Coronet’s K-member. Lastly, we would source thinner head gaskets to increase the compression ratio to achieve 400 horsepower.

Above: The cylinder wear was minimal, and the pistons looked good. Upon further inspection, we decided to reuse the pistons, rods, and crankshaft.

Our well-laid plans hit a bump when we discovered small cracks in our heads. However, we did not let this deter us. After some resourceful networking, with help from Matt Deane, we secured a new pair of EQ heads from Glendora Dodge at a great deal. This experience taught us that in the world of engine swaps, challenges are just opportunities in disguise.

A second problem was with the valve springs. With the new heads, the Comp Cams valve springs require specific retainers to work with stock rocker arms. Dave Trojhan worked with Crosby, and it was determined a set of Comp Cams retainers (PT# 1774-16) would work with the combination.

Above Left: Comp Cams provided a camshaft, valve springs, and a timing chain. We also received a shop banner. Above Right: For the engine components’ fasteners, we selected APR bolts, nuts, and lubricants, which are the best in the market.

When Crosby pulled apart the bottom end, he was pleasantly surprised to see that the cylinder walls of this 160k-mile engine still looked new with a visible cross hatch. The main, rod, and cam bearings all looked good as well. Hence, he did general cleaning and installed a new Napa Auto Parts oil pump (PT# SEP 2244166V).

The bottom end was buttoned up with a new Milodon stock replacement oil pan. Due to their excellent condition, Crosby reused the original lifters and pushrods. We also reused the leak-free Magnum valve covers, giving the engine a sleeper look.

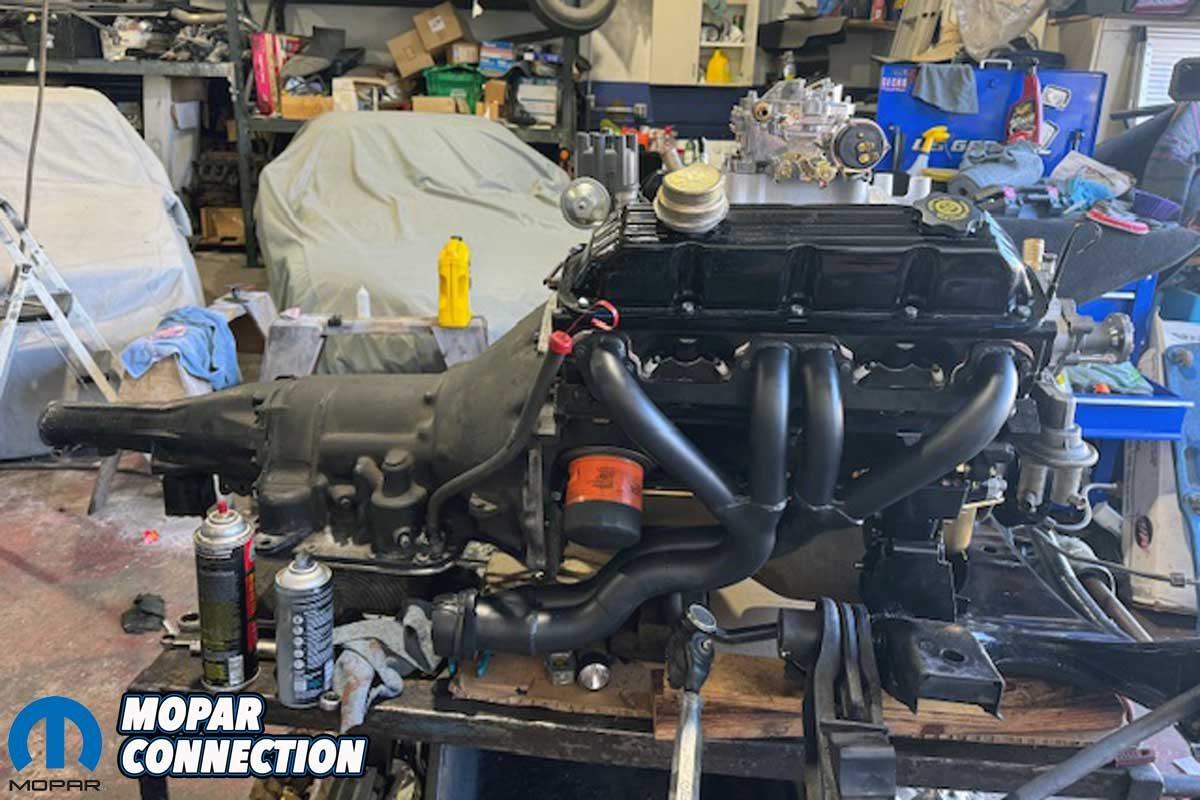

Above: For induction, we selected Edelbrock products. The AVS2 carburetor and RPM Air Gap manifold have an excellent reputation among enthusiasts and fit well into our budget.

To help the 5.9 expel the burnt hydrocarbons, we purchased a pair of Tri-Y headers from MoTech Performance, selecting a black ceramic finish. Schumacher Creative Services (a MoTech Performance company) provided the engine mounts.

We already had a nicely built low-mileage 904 Torqueflite transmission with a 2800-stall PTC converter. We used the stock-weighted Magnum flexplate to mate the 904 to the Magnum’s crankshaft, but we oversized the mounting bolt holes to accommodate the 7/16 bolts used on the neutral-balanced converter.

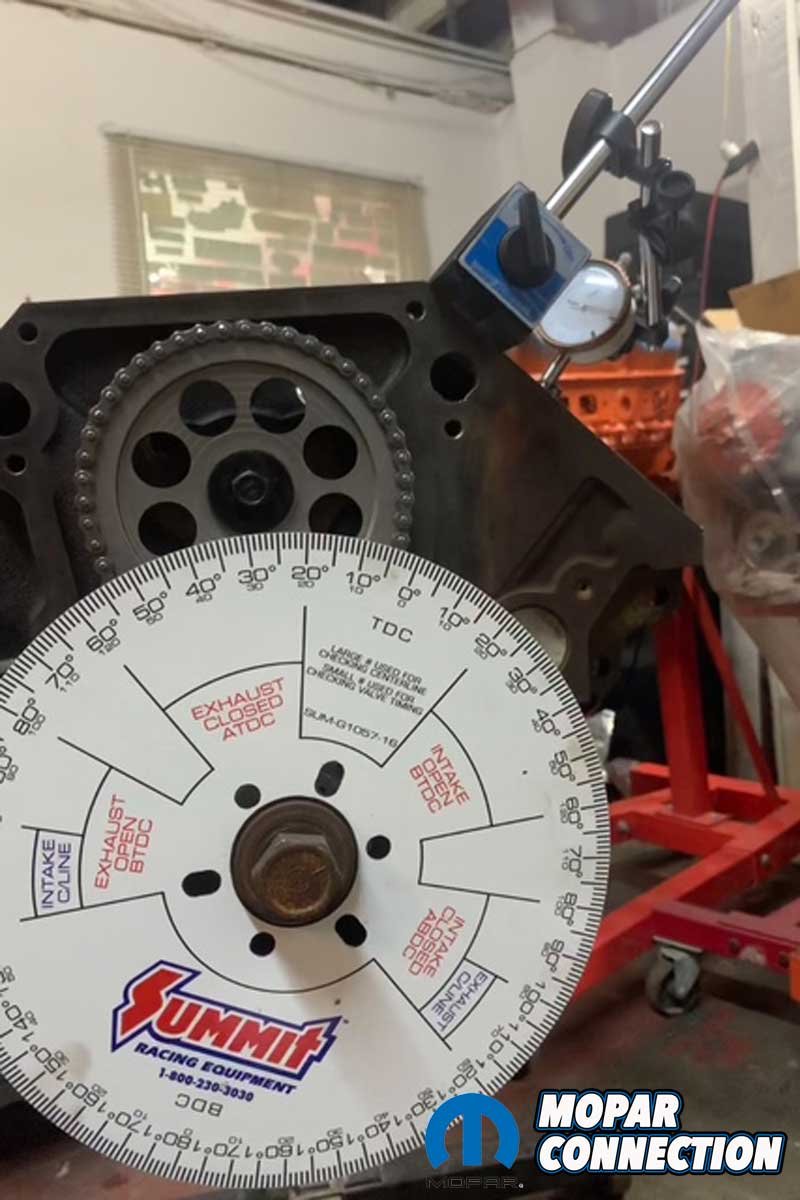

Above Left: The roller camshaft was carefully installed into the Magnum block. Above Right: The camshaft was installed straight up. The Comp Cams double roller timing chain kept everything adequately timed.

We went with a stock Mopar electronic ignition (PT# MOPP4120505) with a recurved distributor. The carburetor was topped with a Mopar air cleaner (PT# MOPP4529026).

We contacted Rory Fontana at Fontana Motorsports in Simi Valley, CA, to install the engine in the Coronet. Fontana quickly pointed out that all the engine’s core plugs were the originals, and although they looked fine, they would be corroded on the inside. He was correct. All the plugs would have likely leaked sooner than later.

Above Left: We located the engine’s top dead center and ensured we had timed the camshaft properly. Everything was perfect. Above Right: The engine was transported back to Fontana Motorsports to be united with the K-member.

Fontana dropped the Coronet’s engine and K-member from the chassis, a common way to swap on Mopars. While the K-member was out of the car, we swapped the steering box for a Borgeson unit (PT# 800126) with its associated U-joint kit (PT# 036425). The steering box is substantially smaller than the factory unit, which provides additional room for headers. The steering ratio is 14:1, making an old Mopar steer like a modern vehicle.

Above Left: The Magnum plugged into the K-member without difficulty. We removed the factory steering box while the engine was at the machine shop and added a Borgeson unit. The Borgeson steering box is substantially smaller than the factory piece, which provided additional room for the headers. Above Center: The Schumacher Creative Services tri-Y header snaked around the Borgeson steering box. Above Right: The Schumacher header provided plenty of clearance around the oil filter without needing a 90° oil filter adapter.

The two-barrel kickdown linkage had to be modified to work with the new Edelbrock four-barrel carburetor. Fontana managed that task for us. Before installing the engine in the engine bay, Fontana cleaned the engine bay and reshot the K-member in black.

As we turned the key, the engine roared to life, settling into a satisfyingly lopey idle. The sound of the cheap turbo mufflers was music to our ears. With the engine being used and the cam being a roller, there was no need for a break-in period.

Above Left: We installed nearly every component that attached to the engine to reduce the difficulty of installing them when the engine was in the engine bay. Above Center: With everything lined up, we did a final clearance check and lowered the Coronet onto the K-member. Above Right: Once the K-member was secured to the chassis, we needed to button up the suspension components and get the alignment angles close enough to drive to an alignment shop.

After a few tweaks from Fontana, the carb was tuned, and the timing was checked. It was a moment of pure satisfaction as we buttoned up the project, knowing we had achieved our goal. The next day, we went down to pick it up and drive it home. We were not expecting the engine to rev up as quickly as it did.

Even with the 2.76:1 rear gears, the Coronet will no longer lose to a Nissan. The peg leg differential will soon be replaced with an Auburn Sure Grip and 3.55:1 gears, which should help the Coronet accelerate more efficiently from a dead stop.

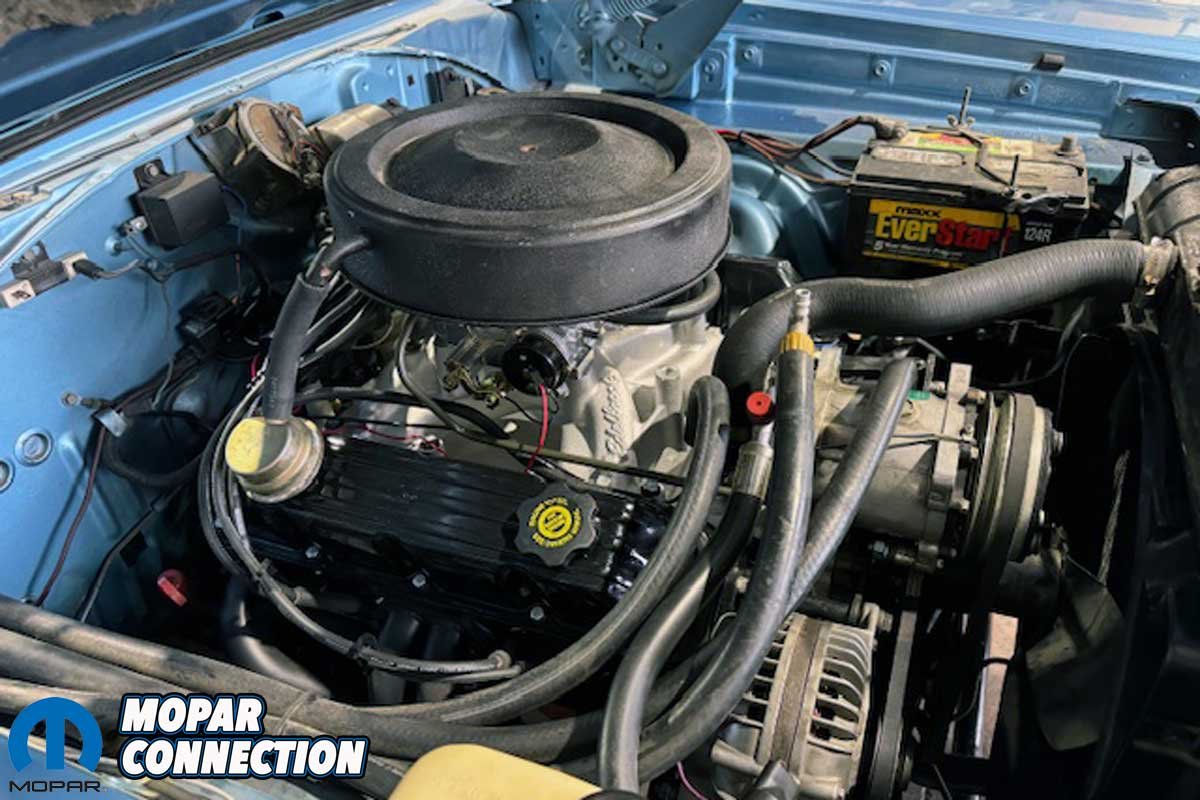

Above: The Magnum looks like it was factory-installed. Except for the 10-bolt valve covers, the engine looks like a 318 with a four-barrel carburetor.

After a few weeks of driving the Coronet, Talon is having a blast. The engine has no leaks and starts quickly due to the finely tuned carburetor. With the engine and transmission squared away, the gear swap will follow before taking the Coronet to an upholstery shop for a new headliner and a rear seat repair.

Above: After finishing up the installation, we started the engine. It sounded great and operated flawlessly. With some tweaking of the carburetor, the engine runs like a finely tuned machine.

It is a blessing to have good people around you. Special thanks to Justin Crosby at BBJ Racing, Matt Deane at Glendora Dodge, Robert Florine at ARP Fasteners, Trent Goodwin at Edelbrock, Dave Trojahn at Comp Cams, and Rory Fontana at Fontana Motorsports for all their help and hard work.