Hughes Engines is arguably the utmost authority when it comes to Chrysler camshafts. They’re one of the few camshaft dealers that has but one thing on their mind: Mopar. You won’t find any Brand-X bump sticks in their catalog and, because of that, their relationship with the Chrysler cam is an intimate one to say the least. Why is that important? Let’s let them explain:

- Why should I use your cams?

- Our cams are designed to take maximum advantage of Chrysler’s large diameter (.904″) lifter size.

- Why should I care about the lifter diameter?

- A flat tappet camshaft’s design is based on lifter diameter. The larger the lifter diameter the faster the rate-of-lift that can be designed into the cam lobe.

- What does rate-of-lift mean?

- The rate-of-lift is the amount of tappet (or valve) lift in relation to the amount of degrees of crankshaft rotation.

- Why do I want a fast rate-of-lift?

- The faster the rate-of-lift, the quicker and harder the air starts to flow in the port. This is the key to a longer, fatter power curve. This is why a roller cam works so well. It has a very fast rate-of-lift.

- Don’t other manufacturers make fast rate-of-lift cams?

- Yes, but they are made for the smaller Ford (.875″) or GM (.842″) lifter sizes because they are much bigger sellers and that is where the money is. They use Chevy lobes on the Chrysler shaft. We call them “Chevy cams.”

- Do I have to install these large diameter lifters (tappets) in my Chrysler?

- No. All Chryslers use the .904″ lifter as original equipment.

- Your cams have very high lift and I’ve been told that Chryslers don’t need high lifts. Why?

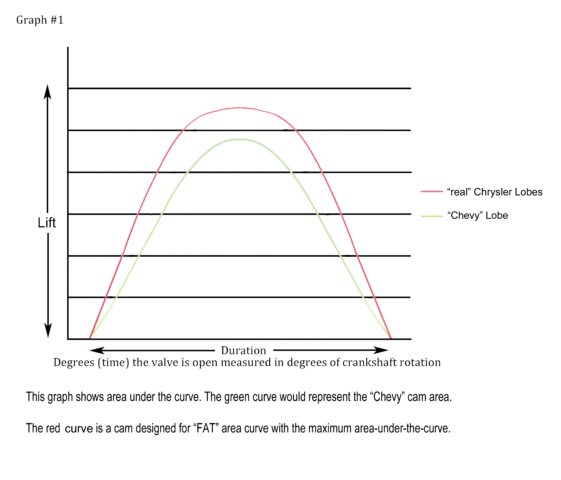

- Yes, our cams do have very high lift relative to our duration at .050″ tappet lift. The reason that this urban legend got started is that stock Chrysler wedge heads quit flowing any more air once the lift gets around .400″ lift. But properly ported they can flow well to over .550″ lift. With stock ports, it is true that high lift does not help power, but the fast rate-of-lift, like ours, does give a tremendous boost to the power range. The graph below shows why this is possible. With the faster rate-of-lift (red curve), there is more time (called area under the curve) for air to flow past the valve. At each degree of rotation, the valve is open higher than it is with a standard of slow rate-of-lift cam (green curve), even with lifts as low as .400″. The fast rate-of-lift is very important.

NOTE: Camshaft size is based on how long the valve is open (duration) NOT ON LIFT, NOT ON LIFT, NOT ON LIFT.

- How can I tell if I’m buying a “Chevy” cam?

- Check the listing in the catalog to see if the same cams are listed for Small Block Chevy and Chrysler wedge engines. For example: Chevy duration @ .050″ 230 with .480″ lift. Hughes Engines Inc Real Chrysler duration @ .050″ 228 (actually smaller) with .524″ lift. Look at the duration at .050″ tappet lift vs. valve lift. The greater the difference, the faster the rate-of-lift. The relationship is even more dramatic in our HTL Max Velocity series of solid lifter cams. Chevy duration at .050 is 250 with .533″ lift. Hughes Engines Inc Real Chrysler duration at .050″ is 250 with .575″ lift.

- Why do you rate cams by duration at .050″ instead of advertised duration like most magazines and many manufacturers do?

- When measuring any duration, it must be measured at some lift point when checking for advertised duration. This point can be anywhere from .004″ to .020″ or at any lift point in between. Some manufacturers may check at one lift point on the opening side and another on the closing side. You could send the same cam to ten different manufacturers and end up with ten different advertised durations. This makes it very difficult, if not impossible, to compare one cam to another. This tact may be by design for some manufacturers so that their cams cannot be compared to anyone else’s. We think a well-educated customer will be a better customer. Therefore, if all cams are compared equally, (at .050″ tappet lift), it makes it much easier for the customer to make an intelligent decision. Most engine builders and cam manufacturers agree with this method of checking.

- Why don’t other manufacturers make “Real Chrysler Cams”?

- The Chrysler market is approximately 3% of the high performance and racing market. Therefore, it would not be very profitable for them to invest much time or research in such a small market. This same situation exists in other Chrysler only areas, such as heads, pistons, manifolds, etc.

- I already have new springs. Why do I need yours? Mine will handle the lift of your cam.

- One of the biggest mistakes you can make is thinking any spring is as good as long as it will handle the lift and isn’t broken. For the cam to operate properly, it must have the proper seat tension to keep the valve from bouncing on the seat and the proper open tension to keep the valves from floating. It should also have enough extra lift over and above the valve lift to keep it from coil binding or stacking up. The fact that “it will handle the lift” answers only one question. You must answer all three at least (seat pressure, open pressure, and maximum lift). Our cams require springs that are usually higher tension on the seat and lower tension open than so called “factory” or “Chevy” cams.

- What about factory high performance and racing cams? How do they compare to your Real Chrysler Cams?

- Most of those were developed over a quarter century ago. We’ve put a man on the moon since then. Chevy and Ford have constantly upgraded and developed better designs, but Chrysler racers are stuck with Ice Age profiles from the factory. Yes, they will work, just like your ancestors used to rub sticks together to make a fire for their evening meal. But you stepped into the 21st century with a microwave oven-now do the same with your camshaft.