It’s nearly unbelievable that it’s been nearly six years since I first fished this 1970 Dodge Super Bee from an open-sided pole barn in Hebron, Ohio. Originally, the ‘Bee came from the Lynch Road, Michigan assembly plant – one of 3,966 coupes built in 1970 – coated in L1 Beige with white C-stripes. Other outliers included the “Power Bulge” hood, A48 Dress Up package that provided a remote driver’s mirror and polished trim inset into the B-pillar, and Burnt Orange interior. The standard faux-wood Rallye instrument panel (found on every 1970 Super Bee) featured an AM radio but no tachometer, not even a clock.

Powering the ‘Bee was a low-deck 383cui V8 once making a respectable 335-horsepower topped with a Carter AVS four-barrel carburetor backed by a 3-speed 727 TorqueFlite automatic (shifted via the steering column), and halted by a quartet of manual four-wheel drum brakes – all standard equipment for the entry-level muscle car. The 8.75 rear came fitted with a Sure Grip spooling a 3.23 ring and pinion. Absent was an optional air conditioner – this ‘Bee came only with a heater. To label this Dodge as “zero optioned” would be an understatement. We couldn’t find evidence that it even came with carpet.

Initially, the plan was to emulate the “ratty muscle” trend being popularized by television shows like “Roadkill”, “Roadkill Garage” and a never-ending chain of YouTube channels producing “revival” videos. A 500-cubic inch stroker motor was already in development at the time and Silver Sport Transmissions was eager to get one of their Tremec PerfectFit Kits in one of our project cars. Equally, I had been wanting to build a pro touring car using Hotchkis Sport Suspension’s TVS (Total Vehicle Suspension) systems for several years and I thought this would make a good candidate.

But that was before I got my hands on the Super Bee and began peeling back the layers to find what was lurking beneath its deceptively “complete” exterior. Gratefully, the ‘Bee was as complete as it was, saving me the trouble of finding it’s more unique features like its dual wrap-around front bumpers. Prior to picking up the car, I was also assured that the frame rails and rocker panels were “solid” – but we both know that term is up for interpretation. The hood was complete scrap; the skin had completely separated from the underside bracing. It flopped and clapped the whole way back to Tennessee.

Once home, I could see that rot had spread throughout the entirety of the Super Bee, making it all but completely worthless. The B-body would require replacement quarter panels, trunk pan, trunk extensions, rear valance, tail light panel, package tray, floorboards, firewall, cross members, trunk lid and hood. The doors, fenders and roof skin were all in decent condition if not reasonably repairable. This need for fresh sheet metal proved problematic as 1970 quarters varied dramatically from ’68 and ’69, requiring a skilled body shop to graft the original single-scoop alcoves and rear caps onto new replacement panels.

Considering the herculean task ahead of us, MCM began tearing the Super Bee down – which we named “ZomBEE” – cutting away as much cancer as we encountered. Almost immediately, the idea of dropping in a powertrain and getting it running as-is was off of the table. This car would need to be completely rebuilt prior to getting it back on the road. Auto Metal Direct (AMD) and US Car Tool (USCT Motorsports) both jumped to the rescue supplying ZomBEE with the sheet metal needed to rebuild and support it. VFN Fiberglass volunteered a lightweight four-pin 1970 Coronet hood. A rear trunk lid was procured from a wrecked four-door. Things were coming together…

…and then they weren’t. Progress on ZomBEE ground to a crawl as other projects took precedence. At a glance, ZomBEE looked worse than before we had started. Square tubing supported the substructure, panels were temporary set-screwed into place. Raw, exposed steel and welds had flash-rusted. The ‘Bee was less of a car than imaginable…and then Mopar called. “We wanna do a project together,” the voice on the other end beamed. “Let’s put a [new] HEMI in one of your cars!” Certainly we’d be certifiably insane not to take up the offer, but which car? That’s when they inquired about ZomBEE. “How about that Super Bee?” I winced at the question.

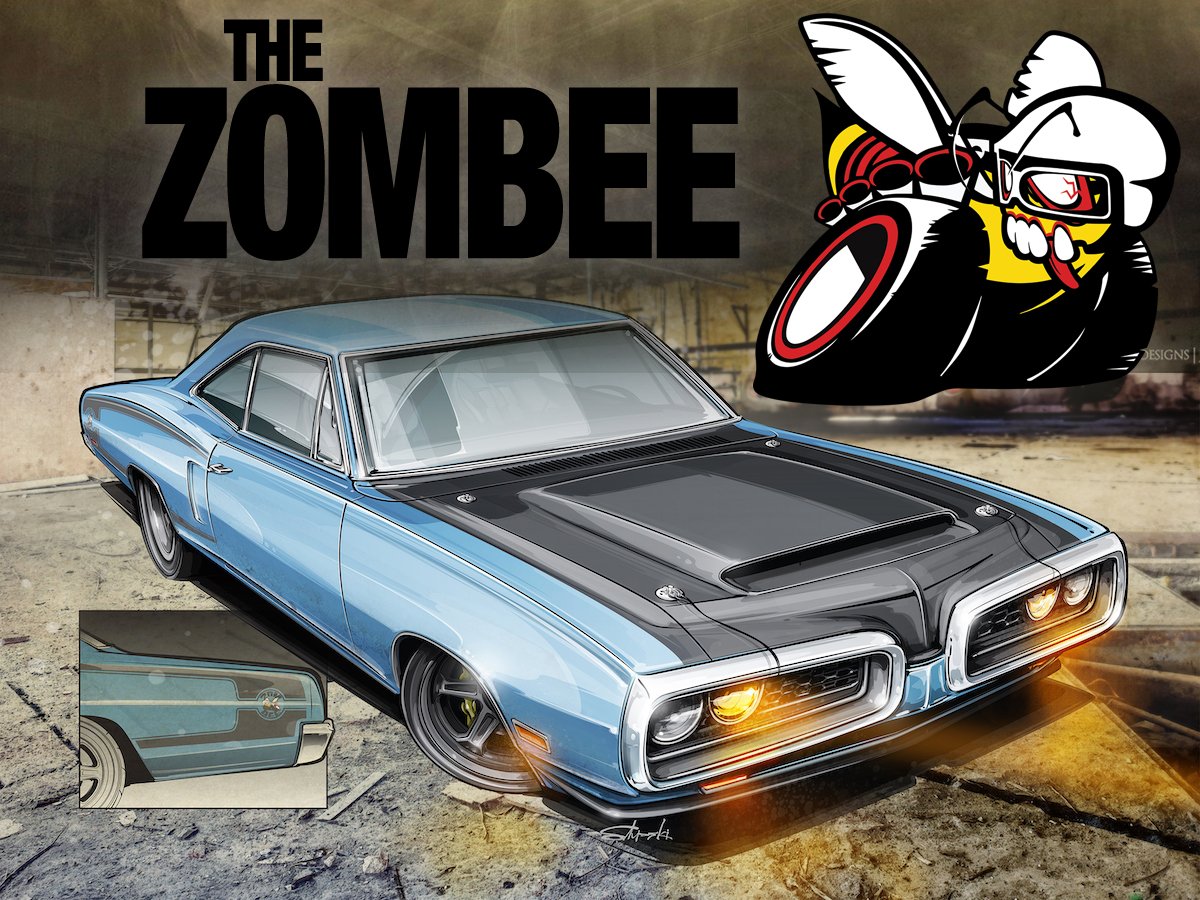

Thankfully, my hesitancy was unfounded. Direct Connection introduced Mopar Connection to Finale Speed, makers of the all-carbon fiber 1970 Dodge Chargers being sold through the Power Brokers program. Helmed by JD Rudisill, Finale Speed quite literally scoffed at ZomBEE being (as I put it) a “nightmare.” The Super Bee was delivered to Finale Speed’s facility in Yukon, OK and the plan was set in motion: ZomBEE would be restored to its original shape with only slight improvements: including USCT Motorsports’ Stage 3 chassis stiffening kit, 3-inch wheel tub extensions, and a fiberglass hood customized with a modern Demon scoop.

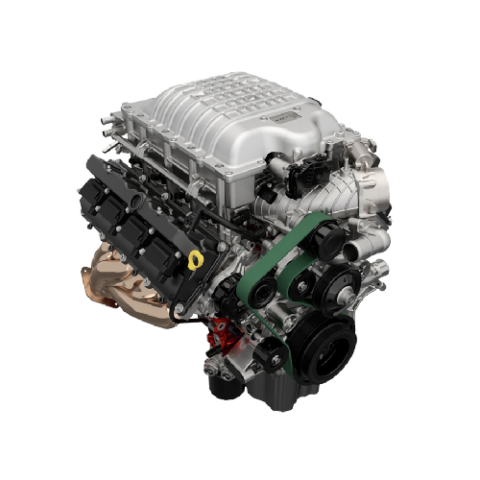

The revival of the Direct Connection catalog and directing customers toward its Power Brokers program was the new priority. The catalog presents enthusiasts with six engines: four standard production HEMI’s – 383hp 5.7L (345cui); the 6.4L (392cui) making 485hp; the supercharged Hellcrate 6.2L (376cui) and its 707hp; the Redeye Hellcrate 6.2L (376cui) making 807hp; and the two 7L (426cui) monsters: the 1,000hp Helephant and the over-the-top 1,500hp variant of the same name. Because the nature of ZomBEE was now to embody the off-the-shelf offerings available through the Direct Connection catalog, I felt the factory production Redeye Hellcrate was more appropriate.

The entirety of Project ZomBEE is now to serve two purposes: first, to illustrate the full capabilities of Finale Speed’s team in restoring classic cars despite how poor the condition as well a demonstrating proper steps taken to do so; and second, to meticulously detail every single step necessary for the average enthusiast to swap in a modern HEMI engine using the tools and resources provided by Direct Connection and the automotive aftermarket. ZomBEE will be the platform used to answer questions regarding fitment, plumbing, wiring and clearances. Since ZomBEE will remain a torsion bar-and-leaf spring configuration, everything we do on the ‘Bee will be perfectly replicable.

The details of the finished vehicle are of course, not entirely cemented but thus far this is the picture we can paint: The powertrain will consist of mainly Direct Connection components – the aforementioned 807-horsepower Redeye Hellcrate 6.2L, Direct Connection’s Hellcrate non-EO engine controller, PCM, harness and installation kit, 45º oil filter adapter kit, rear oil sump pan & pickup kit, DC’s alternator, power steering and A/C expansion pump accessory kits, and DC exhaust manifold kit; Silver Sport Transmission’s PerfectFit Kit Tremec TKX 5-speed and McLeod RST twin-disc clutch; a Currie Enterprises’ “60 Series” Dana 60 fitted with an Eaton TrueTrac with 3.54 gears and 35-spline axles; and Baer Pro+ 6P 14″ disc brakes and Remaster master cylinder.

At one point, I had hoped to run the Demon 18×8 5-spoke wheels, but seeing the modern wheel pattern is 5 x 115mm, and the vintage pattern of 5 x 4.5″ equals 5 x 114.3mm, we’re leaning towards a set of Year One’s 17×8 Rallyes in front and soon-to-be-widened 17×9’s in back. All of this will ride on Hotchkis Sport Suspension’s complete TVS system. We’ll use a Borgeson power steering box, Frostbite aluminum radiator and Flaming River steering column and Tuff wheel. We’ll be turning to Holley for all of our fuel system needs. Lastly, the interior will be nearly stock black livery from Classic Industries and Year One, save for some improved instrumentation from Redline Gauge Works and Classic Dash.

Externally, once Finale Speed performs the miracle of bringing this ‘Bee back from the brink, the entirety of the car will be painted in PAG Ceramic Blue – the same color used on the last ACR Viper. We also plan on grafting a replica wide-mouth 2018 Demon scoop onto the VFN fiberglass hood coated in a textured layer of near-factory-correct Organisol. Lastly, we’ve commissioned a pair of customized C-stripes to be made using our unique “ZomBEE” logo (shown above). It’ll be a subtle change that you won’t notice unless you look closely. Again, we wanted the ‘Bee to be a good representation of what the would-be HEMI-swapper would begin with.

This build is going to take some time both to execute and to document. Once it builds momentum, expect monthly articles tackling each facet of HEMI-swapping a classic Mopar muscle car as well as a steady stream of videos covering each stage of the project. Partnering with Mopar, Direct Connection, Finale Speed, Silver Sport Transmissions and each of the manufacturers included here and yet to be listed is a true honor and we’re excited to provide the most useful, informative content we can on this topic. We hope you’re as excited as we are!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by