Improper driveline alignment can be the bearer of bad news in a multitude of ways. Vibration, premature wear, and ill-fitting parts can all be symptoms of something that’s not all that difficult to fix, especially when it comes to bellhousing runout.

So important is this alignment between transmission and crankshaft centerline that new Tremec transmissions actually require the total indicated runout (TIR) to be less than 0.005” for warranty purposes.

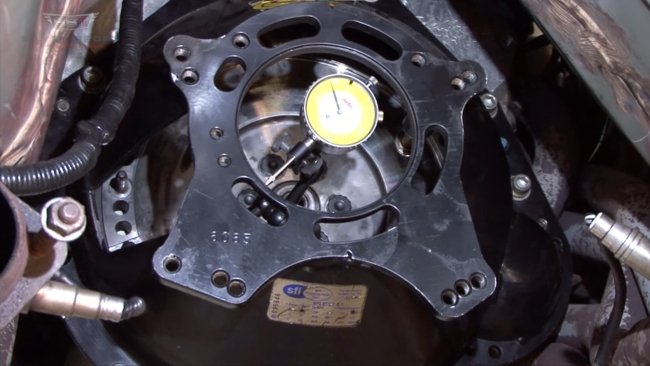

While the task can seem intimidating, Shane Sullivan and the crew at Silver Sport Transmissions (SST) were able to achieve in-spec. positioning in less than ten minutes of video magic. Setup involves bolting the bare flywheel to the crankshaft and installing the bellhousing.

With a magnetic base indicator attached to the flywheel, a zero point can be marked on the face of the bellhousing to begin. After manually rotating the engine one full revolution to make sure the dial indicator returns to zero, official measurements can be taken.

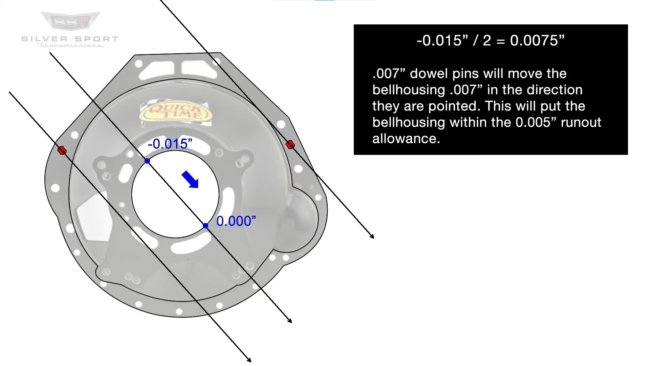

The key value is the most positive number in one revolution. Once it’s marked, it acts as the “new” reference point to gauge the necessary direction of pin installation. Taking another measurement 180 degrees from that new point and dividing the number by two will result in the starting TIR.

With direction and magnitude calculated, SST’s offset dowels make the move easy with high point markings and an allen screw to lock rotation. Once within Tremec’s specification, the results get emailed to SST for warranty validation.