When the ’60s and ’70s Mopars rolled off the assembly lines, the vehicles usually came equipped with a 35-amp, 46-amp, 60-amp, or 78-amp alternator depending on the vehicle year and the standard and optional equipment installed. While these amperage outputs were acceptable when the cars were new, additional components, such as aftermarket radios, electric fuel pumps, electric fans, and the need to charge electronic devices creates an amperage draw that quickly exceeds the OE alternator’s rated output. To keep up with the additional amperage demands of today’s electrical components, enter Mopar 110 AMP Alternators for 1960-1987 V8 and Slant Six Mopars.

The original equipment manufacturer (OEM) “Square Back” case design means the alternator will fit into the factory mounting brackets, and the belt will adequately adjust and maintain the desired tension. The alternator features an internal regulator (mounted inside the case), 1-wire hook-up (reduces the wiring complexity), internal fan, and a single V-groove pulley. The Mopar Alternators incorporate heavy-duty copper wound coils, spike resistant diodes, and the output exceeds all OEM requirements.

Above left: The Mopar 110 AMP Alternators are for 1960-1987 V8 and slant six Mopars. The alternators feature an internal regulator, 1-wire hook-up, an internal fan, and a single V-groove pulley. The Mopar Alternators are available in three different finishes; this one is a natural satin finish. Above right: The Mopar Alternators incorporate heavy-duty copper wound coils, spike resistant diodes, and the output exceeds all OEM requirements. All the internal parts of each alternator are 100% new. This alternator will provide some shine to the engine bay in its chrome finish.

The Mopar Alternators come in three finishes. The first finish is a natural satin that mimics the factory appearance when installed under the hood. If there is a desire for some bling, a chrome finish will add some pop to the engine bay. Lastly, the alternator can be ordered in the signature Black Crinkle finish to match a pair of Mopar Black Crinkle cast aluminum valve covers. Regardless of the finish selected, all the internal parts are 100% new; there are no refurbished or remanufactured components in any of the alternators.

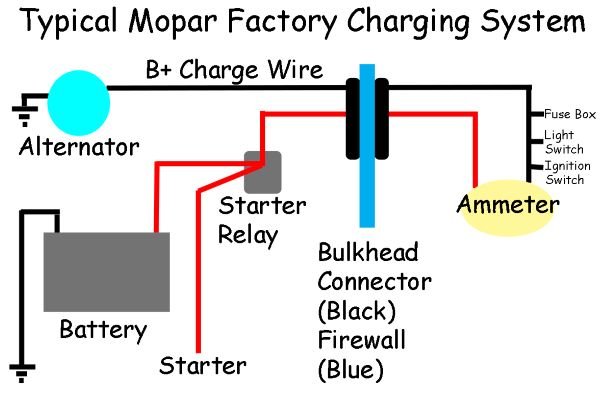

When installing a 110-amp alternator, a few wiring modifications are required to replace the original low-amperage wiring. The bulkhead connector terminals are a concern in a normally operating charging system, and even with low circuit amperage, the ammeter can also be problematic. The ammeter is in series with the charging system. Therefore, all the charging system current must flow from the alternator charge wire to the bulkhead connector. From the bulkhead connector, current flows to an ammeter terminal, through the ammeter, and back to the bulkhead from the second ammeter terminal.

Above: With an original equipment manufacturer (OEM) square back case design, the Mopar 110 AMP Alternators will fit into the factory mounts without the need for modifications. The alternator is a simple 1-wire hook-up, which reduces the wiring complexity. The signature Black Crinkle finish will match a pair of Mopar Black Crinkle cast aluminum valve covers.

Back at the bulkhead connector, the current flows to the rest of the charging system. If there is a loose terminal connection at the bulkhead connector or loose screws at the terminals of the ammeter, heat will generate. As the heat increases, melting of the bulkhead connector or the instrument cluster at the ammeter will occur at the point of failure. Now add additional electrical components and an alternator capable of generating more current to meet the electrical loads; the problems only worsen.

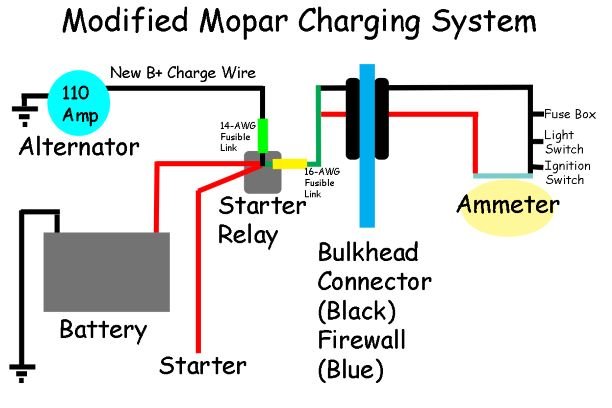

The recommendation for the charging system problems is to run a 10-gauge (minimum gauge size) alternator charge wire from the alternator to the starter relay terminal. The charge wire should be protected with a 14-gauge fusible link at the starter relay terminal. The two wires that run to the ammeter should be joined together in the engine bay, and a 16-gauge fusible link should attach the two wires to the starter relay terminal. Remove the other ends of the ammeter wires from the ammeter terminals and connect the wires.

Above left: With a factory-rated alternator, the charging system usually meets the needs of a ‘60s or ‘70s Mopar, but when additional electrical loads are added, problems may arise. The bulkhead connector and the ammeter are in series between the alternator and the power distribution terminal at the starter relay. If a greater amperage output alternator is installed for the additional electrical loads, the bulkhead connector and the ammeter wiring may fail. Above right: If a Mopar 110 AMP Alternator is installed (or any high-amp alternator), it is recommended that the B+ charge wire runs to the starter relay terminal through a fusible link. The engine bay ammeter wires need to be joined and attached to the starter terminal, also through a fusible link. Lastly, the two ammeter wires at the ammeter should be coupled. This will bypass the ammeter but still provide current to the fuse box, light switch, and the ignition switch. The ammeter will no longer operate with this modification.

By joining the wires, it will bypass the ammeter, but the operation of the under-dash circuits attached to the ammeter wiring will continue. Although the ammeter wires are no longer required to carry the current of the entire charging system, the wires and terminals at the bulkhead connector and under dash need to be in good condition. For trouble-free operation, replace the wires and terminals at the bulkhead connector, as necessary.

After the installation of additional electrical components, Mopar 110 AMP Alternators provide the required amperage for the increased charging system load. The square back design allows the alternator to fit into the factory location, and the simplicity of the 1-wire connection makes installation a snap. With three different finish options, these alternators will meet the needs of every Mopar enthusiast. If a higher-output alternator is in your future, visit ProformParts.com for more information.

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider!

Mopar Connection Magazine – The ONLY Daily Mopar Magazine © 2022. All Rights Reserved. Mopar Connection Magazine is the ONLY daily Mopar Magazine bringing you the latest Mopar news, technology, breaking news, and Mopar related events and articles. Find out the latest information about Mopar, Mopar products and services, stay up to date on Mopar enthusiast news, dealership information and the latest Mopar social media buzz! Sign up for the Mopar Connection Magazine newsletter for the latest information about new products, services and industry chatter. Mopar Connection Magazine is the best and only source you need to be a Mopar industry insider! by

by