Recently, we had been struggling with the direction of “Brazen,” our long term project ’69 Dodge Charger R/T. Initially inspired by “Dandy” Dick Landy’s AHRA Stock class ’68, ’69 and ’70 Chargers, we wanted to build a car to run 10’s in the quarter, yet be able to drive around town as much as possible. Admittedly, not until we installed the FAST (Fuel Air Spark Technologies) EZ-EFI 2.0, had we been doing much of either. Thus far, our aggressive no-holds-barred approach worked fine for building a 10-second car, but steep 4.56 gears and a reverse-pattern, manually-shifted TorqueFlite 727 spinning a neck-snapping 3,600 rpm stall converter was anything but street friendly. Frankly put, we needed to add some civility to this car quick.

Certain steps were made to “soften” this car from being a truly rough-and-rowdy racecar: As you’ll recall, our 535ci “Wicked Wedge of The South” is spinning a completely hydraulic roller valve train from COMP Cams, eliminating the need for Saturday morning valve lashing sessions, while easing the engine’s harsh idle without losing its aggressive cam profile; we installed HushMat throughout the interior (floors, door panels and trunk); and we even installed a single rubber motor mount on the passenger side (with a solid on the driver’s side) to soften the torsional vibration from the engine when hard under throttle. And like Landy’s Dodges, we kept the interior intact (save for a center console) including the rear bench.

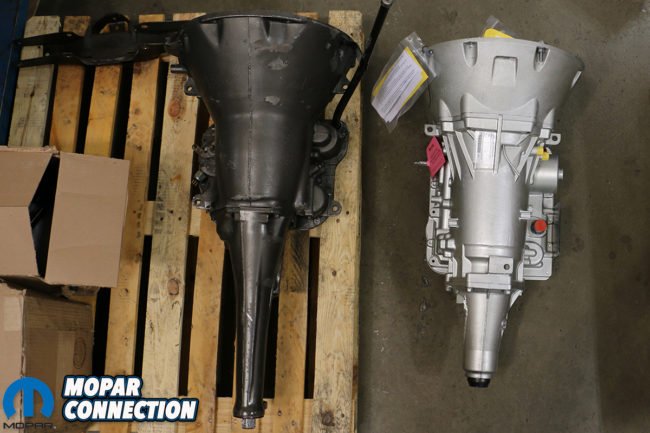

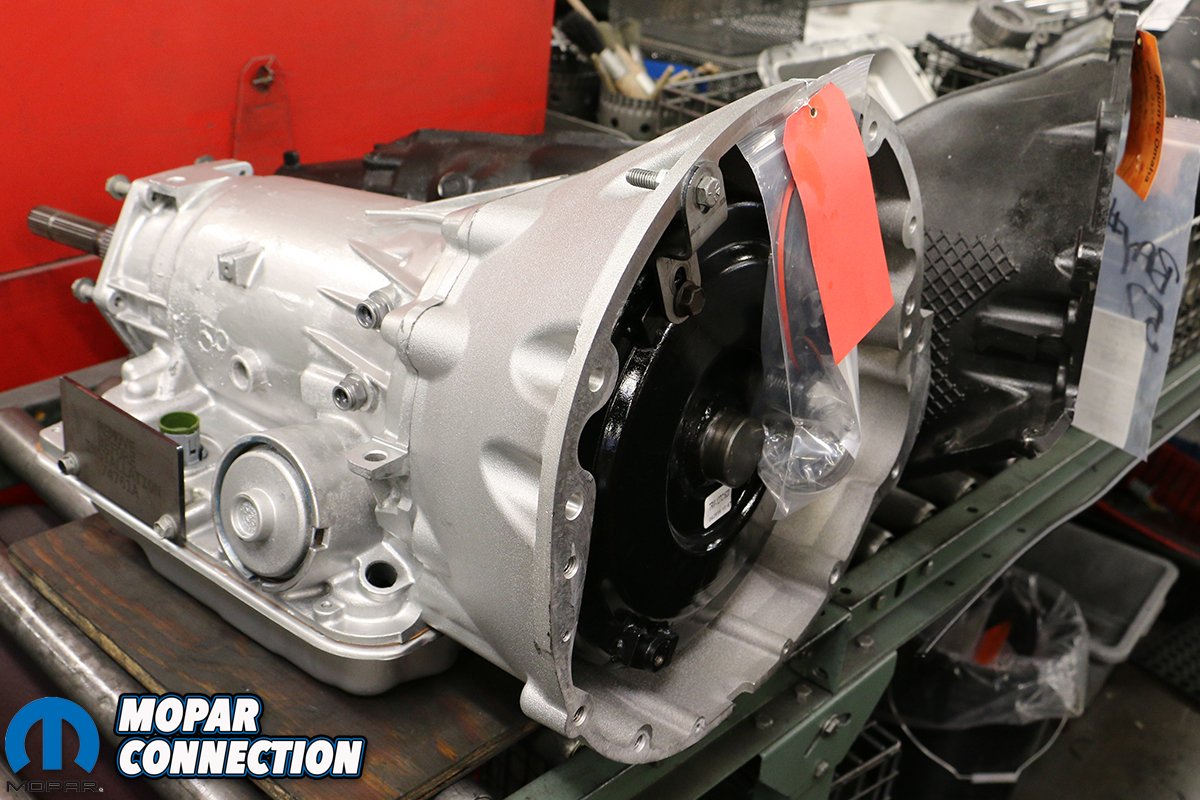

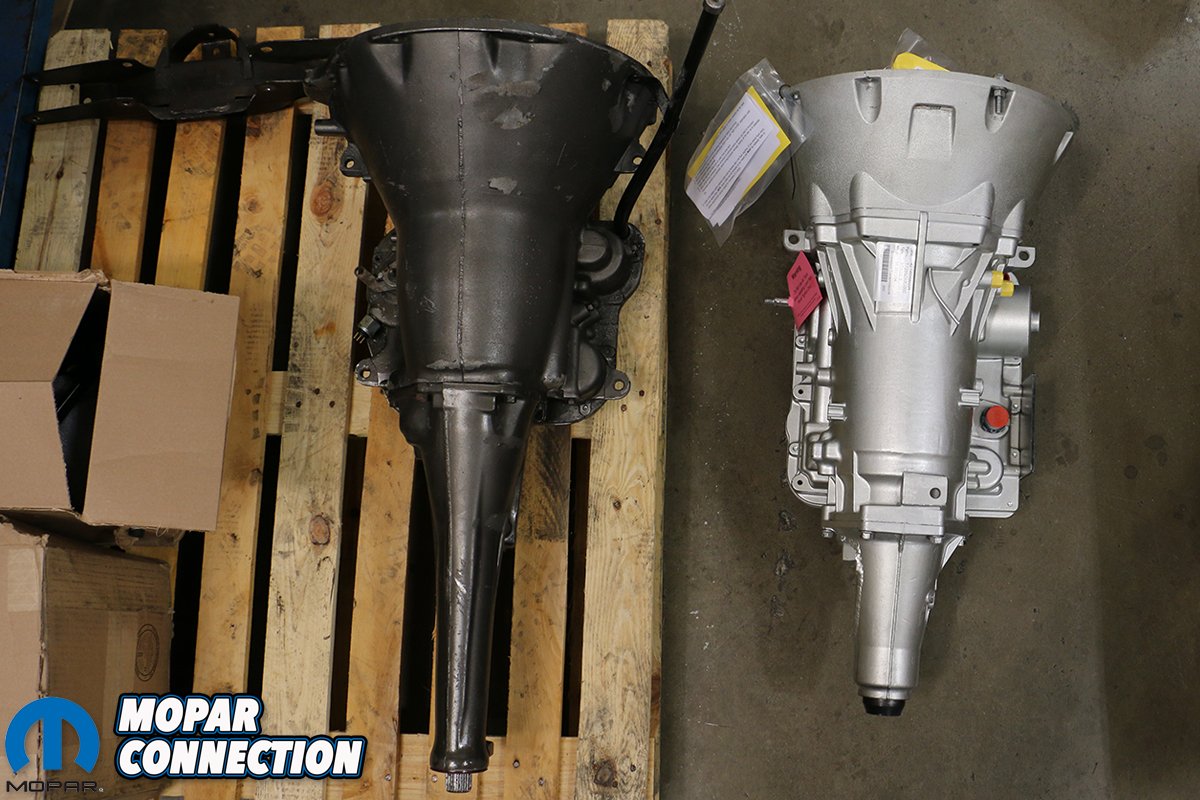

Above left: Every A41 PerfectFit overdrive transmission begins at Certified Transmissions in Omaha, NE. Certified is one of the largest, most trusted names in transmission remanufacturing. Above right: Rest assured, Certified uses genuine Mopar OE-replacement and performance parts where possible.

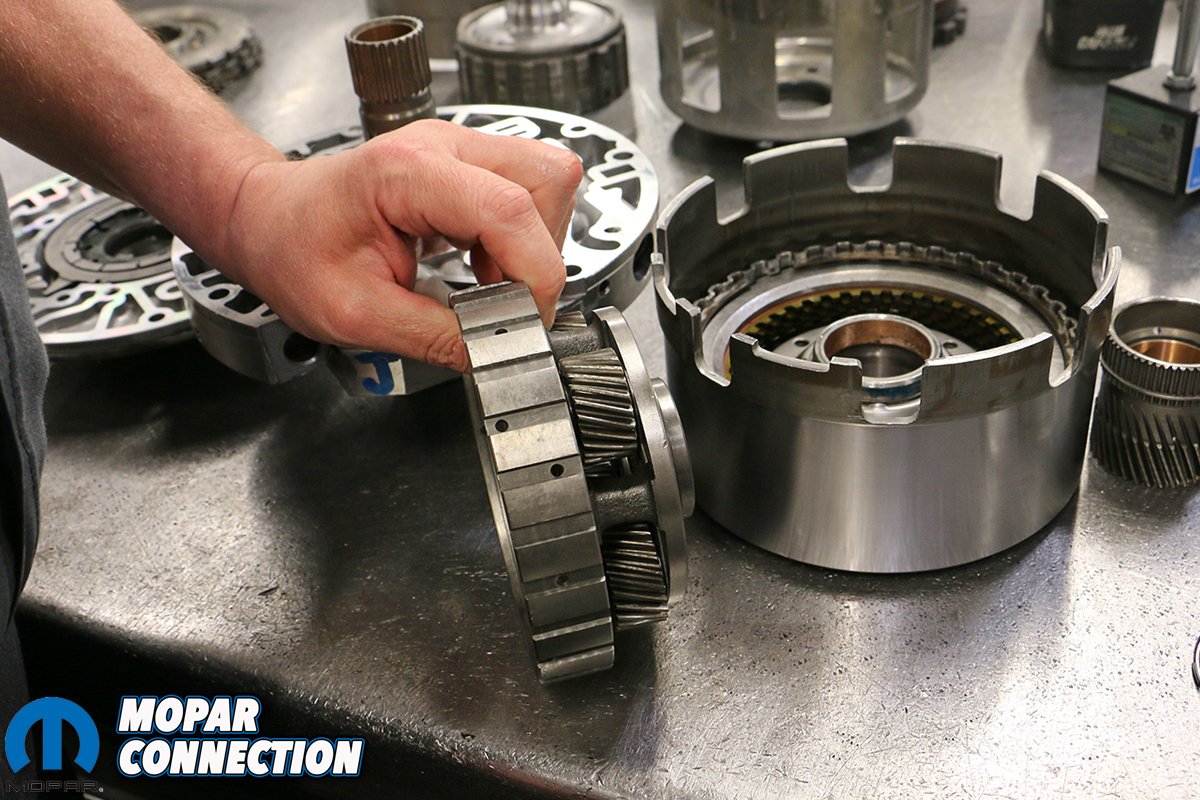

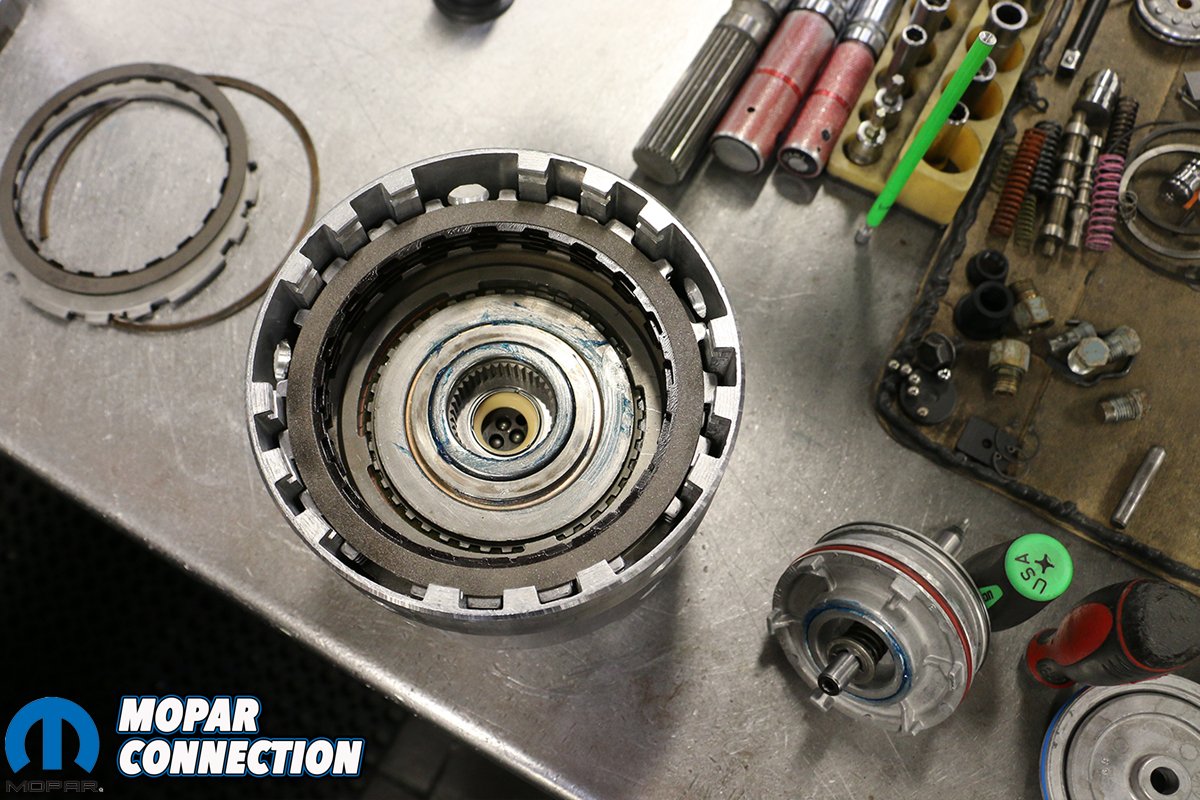

Above left and center: SST offers three stages of possible performance, since we exceeded even its Stage 3 kit, SST and Certified labored to ensure that this “Stage 3 Plus” could withstand our Charger’s 700 lbs. ft. of torque by using 4-pinion planetaries, hardened sun shells, beefier sun gears, a heavy-duty band, improved clutch packs, and a few other tricks. Above right: The pump and stator are hand assembled and rigorously tested prior to assembly.

Above left: Every transmission to leave Certified Transmission is dyno tested, spun up (and in many cases, beyond) normal operating speeds and checked for leaks. Above right: Once cleared, the A41 is crated up and sent to Silver Sport Transmissions.

In light of all of that, spinning the engine at 3,750 rpm while driving at 65 mph was unacceptable both in terms of fuel consumption and more importantly, engine longevity. Since we didn’t want to change our rear gear or tire combination as that would injure our 10-second goal, we needed to find a different route. We reached out to Jack Silver of Silver Sport Transmissions. In addition to a selection of TKO and Magnum 5- and 6-speed manual transmission swaps, SST’s PerfectFit Kits also include a very unique A41 4-speed overdrive automatic offering. The electronically-shifted overdrive was built to fit most all classic GM, Mopar and Ford muscle cars through the use of a single transmission housing and adapting different bell housings and tail cones for each application.

Compared to the outgoing 727 TorqueFlite, the A41 offers not just a superior overdrive gear (offering a 30-percent reduction in cruising rpm), but lower gear ratios throughout the pattern; from Chrysler, the original big block ratios were first: 2.45-to-1, second: 1.45-to-1, and a final 1-to-1 ratio. For the A41, those improve dramatically: 3.06-to-1, 1.63-to-1, 1-to-1, and a final 0.70-to-1. All of this adds up to snappier acceleration and a quicker rate to that final .70-to-1 overdrive gear. In addition to far better shifting quality provided by the stand-alone electronic controller, the A41 comes with a lockup torque converter with optional stall speeds (10-inch 3,100-4,000 rpm stall, or a 10-inch 2,800-3,600 rpm stall).

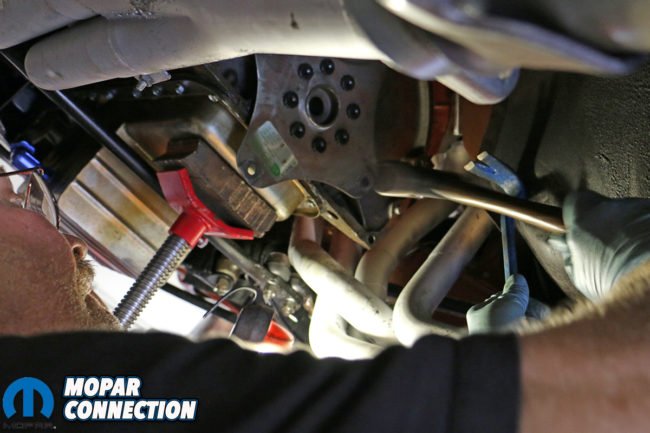

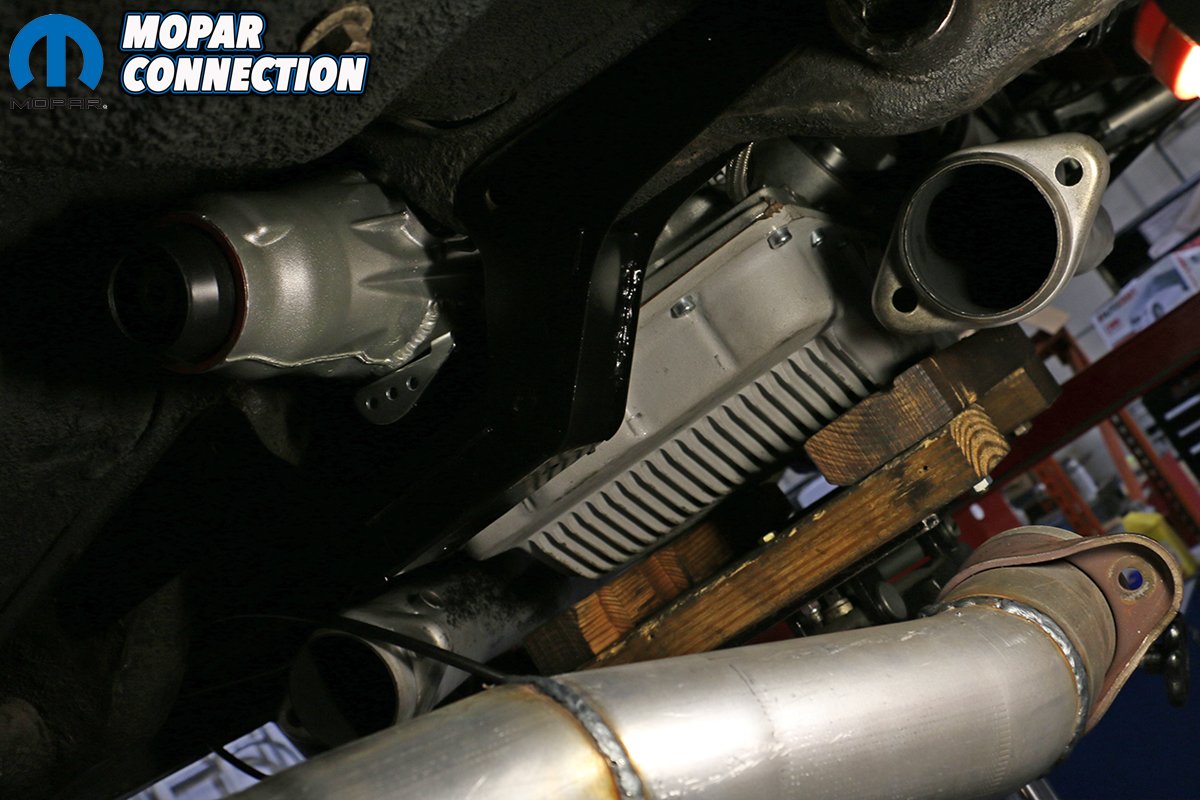

Above: With Brazen ready to undertake the transmission transplant, we drained all the fluid, double-checked our measurements (SST has done all of the legwork possible, but it’s all but impossible to account for every header and exhaust combination. Some measuring is recommended).

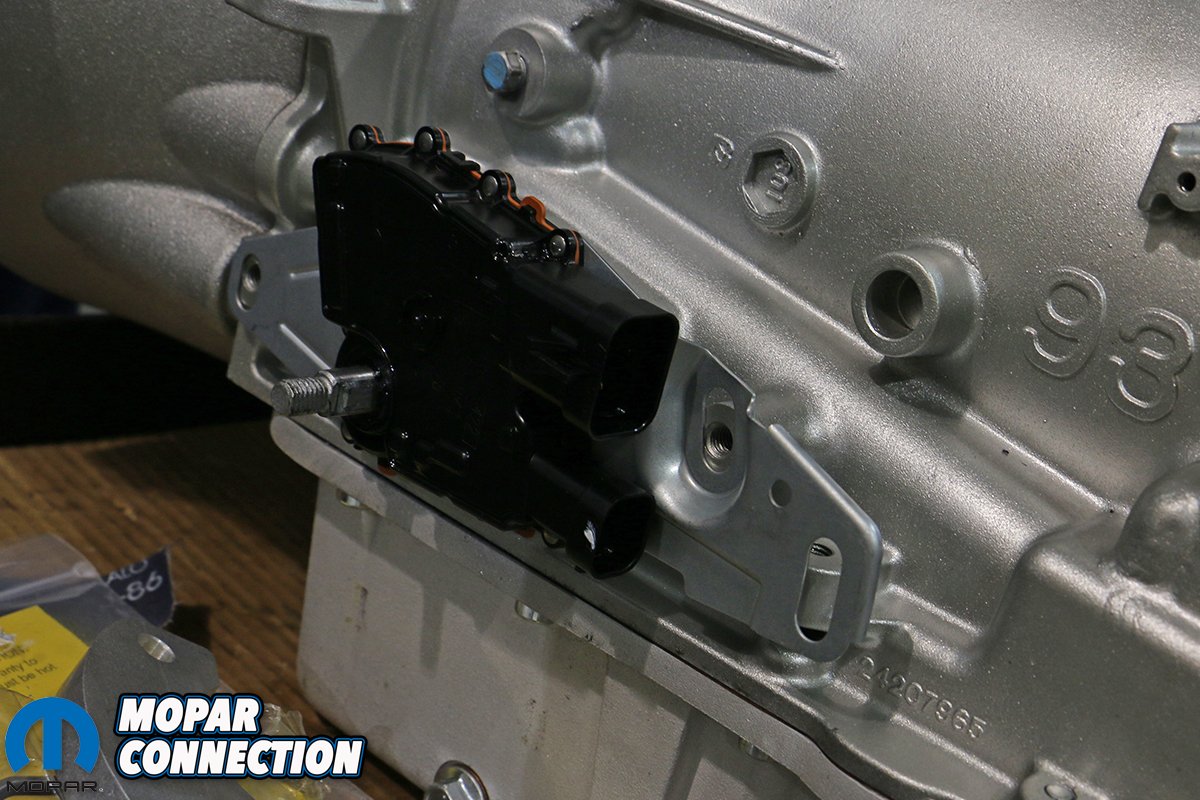

Above left and center: So that’s where 2nd gear went. Well, it’s a good thing we’re doing a transmission swap! (Maybe we can do a third rebuild story on this 727 at a later date.) Above right: Although the tail cone is significantly shorter, the A41 is surprisingly more narrow at the pan flange (by nearly 2-inches) than the 727 TorqueFlite, although the pan and shifter solenoid favor the passenger side, requiring a little transmission tunnel sculpting.

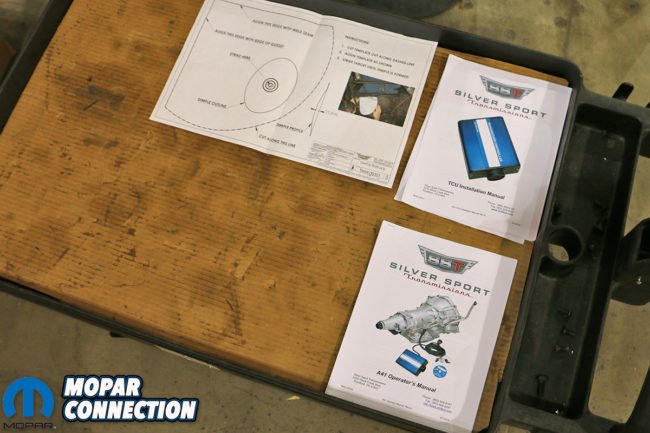

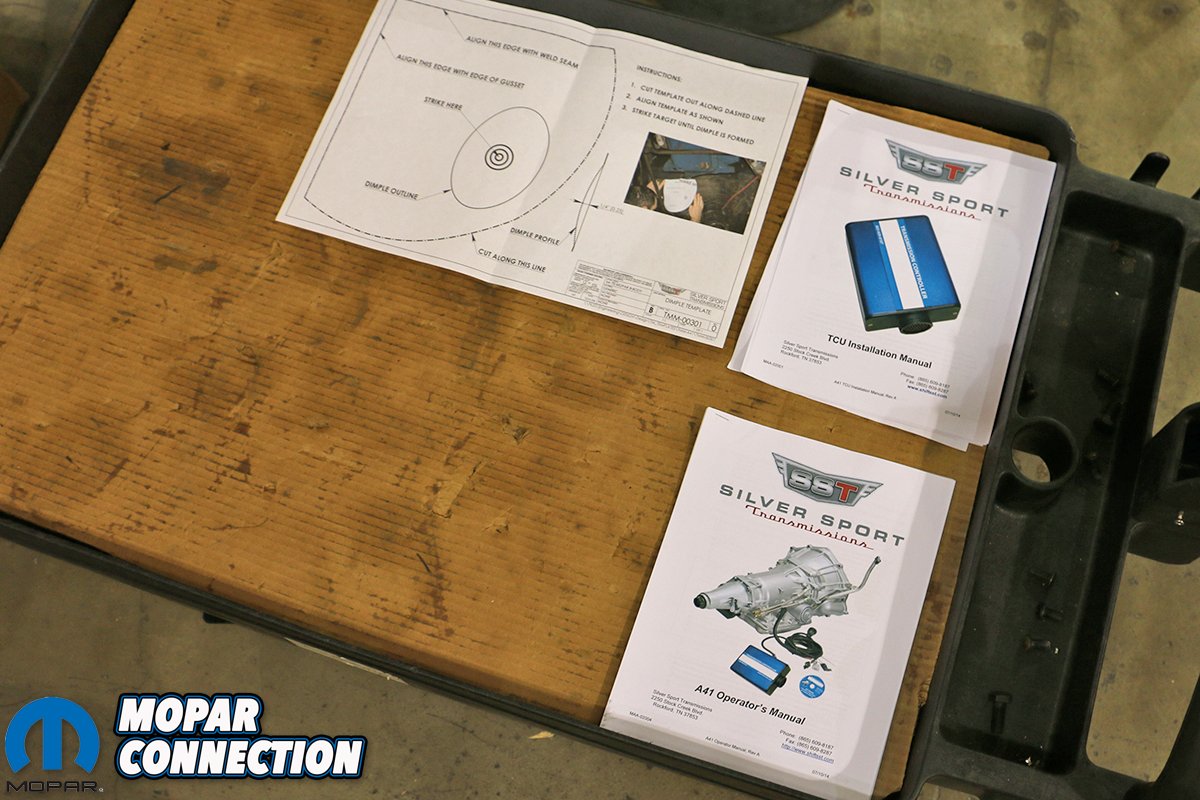

Above left: In addition to the overdrive itself, SST’s PerfectFit kit comes with everything imaginable to properly install your new electronically-shifted A41 – Above right: – including a full bevy of full color illustrated instructions to guide through each step of the process.

Built by hand by Certified Transmissions to SST’s specifications, each A41 begins life as a bare 4L60E center section. The reasons why the 4L60E was chosen for the kit are multiple: first, they’re plentiful with a very large aftermarket supply of top grade performance parts; second, the 4L60E has a removable bell housing and tail cone, allowing SST to cast custom bell housings for both big and small block Chrysler applications (with correct starter positioning); and lastly, it’s universally considered one of the most durable 4-speed overdrive transmissions in the hobby today. In fact, the hardest part about installing an A41 is getting over the fact that Mopar didn’t offer it in 1969.

Each A41 is rebuilt to precise parameters befitting the customer’s specific build; SST offers the A41 in three stages: Stage 1 (450 lbs. ft. of torque), Stage 2 (550 lbs. ft. of torque) and Stage 3 (650 lbs. ft. of torque). Because we were producing 700 lbs. ft. of torque, considerably more than SST’s offered Stage 3, Silver conferred with Peter Fink, President of Certified Transmissions, who returned stating, “It [wouldn’t] be a problem.” Creating a “Stage 3 Plus” A41 included beefier sun gears, a heavy-duty band, improved clutch packs, four-pinion planetaries, and a few other tricks. After assembly and leak testing, Certified’s technicians dyno tested the transmission prior to shipping it to SST.

Above: Prior to ordering your A41 kit (that is, if you’re going to be performing the installation yourself), SST will guide you on properly measuring your driveshaft so that a replacement can be custom made and balanced for your car.

Above left: SST’s Dick McCord measures and marks where the dimple in the transmission tunnel needs to be made, as well as how deep it needs to protrude. Above right: Using a ball peen hammer and the rounded edge of a pry bar (we suggest a body dolly), we pushed out the floorboard just enough to clear the A41’s shifter solenoid.

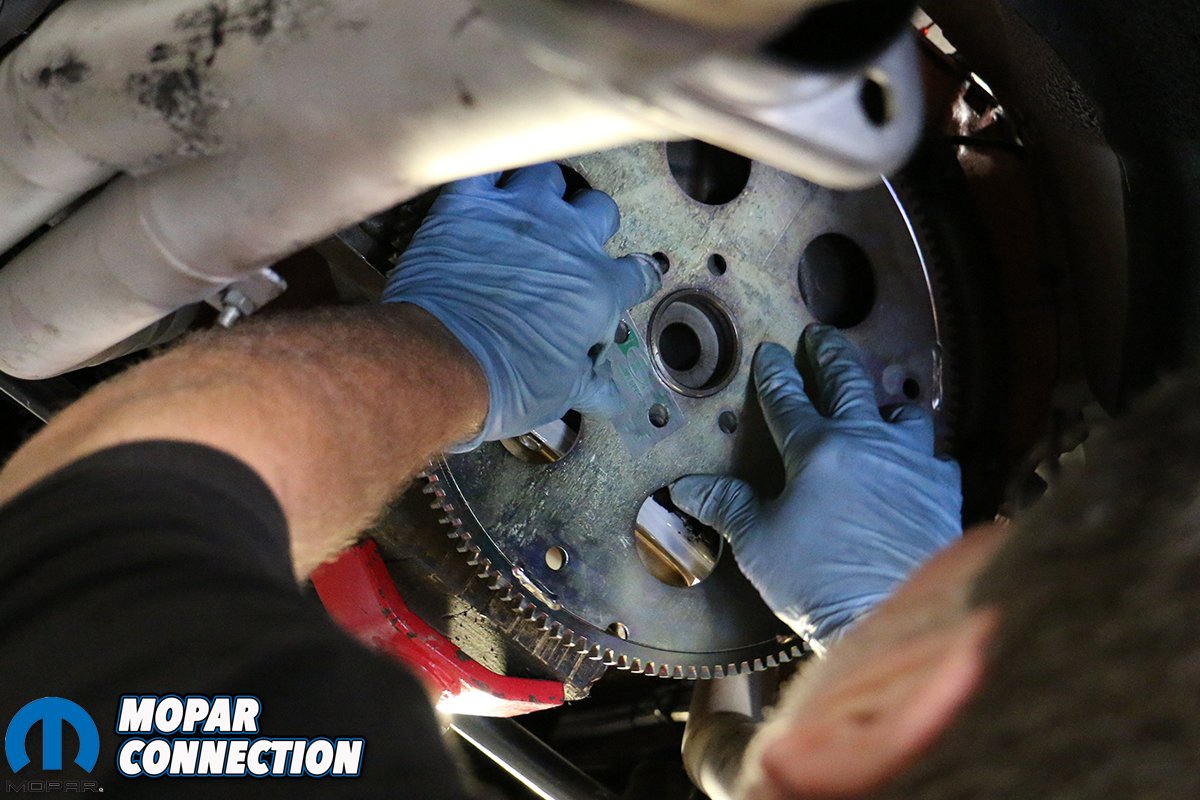

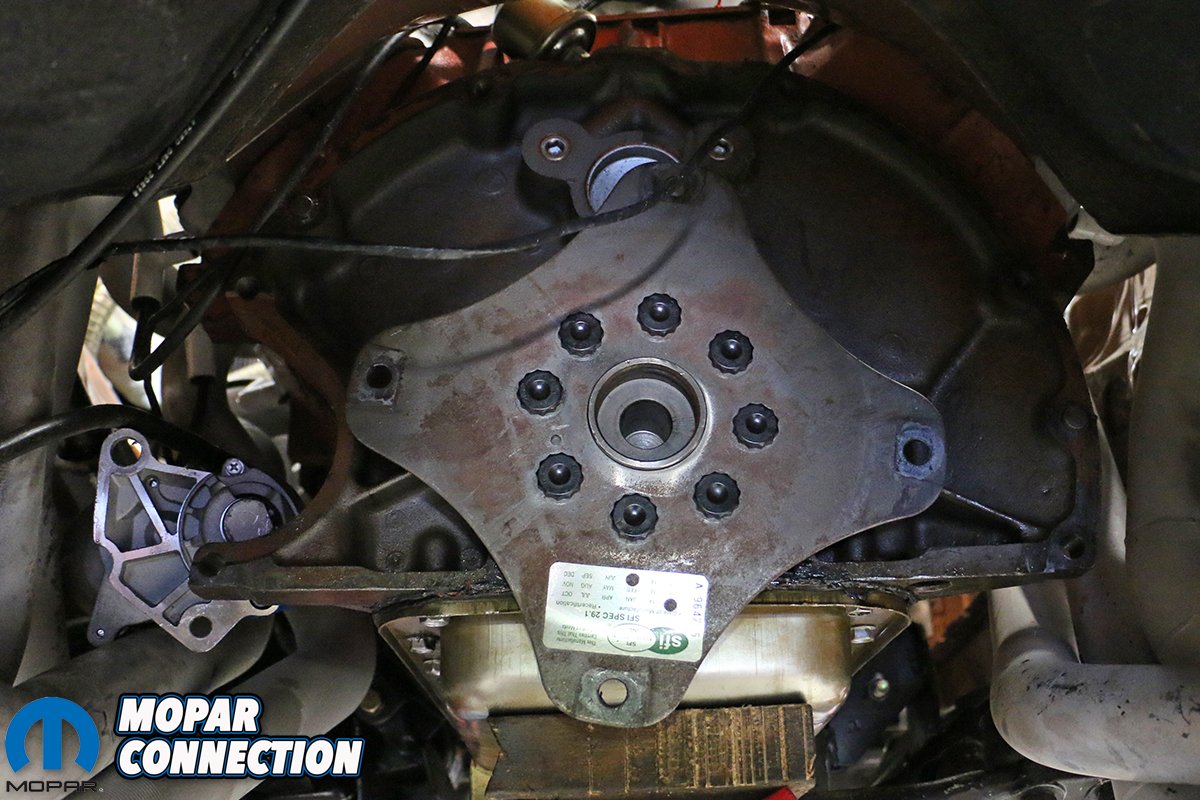

Above: Because the A41 runs a toothless GM-style converter, you cannot use a traditional Chrysler flywheel, but rather a customized-by-SST Chrysler manual transmission flywheel (to engage your starter) that will bolt up to your crank’s flange as well as the lock up converter.

Once there, we met with Jack and the team and loaded Brazen onto their lift. While our Charger was being prepped for surgery, we took a closer look at the complete A41 kit: Every PerfectFit Kit comes with all of the hardware, fittings and of course, components to fit your specific application. The list is considerable: the A41 automatic transmission, custom-cast aluminum bell housing, OEM-style dipstick and tube, auxiliary oil cooler (for high performance Stage 2 and 3 only), a 10-inch lock up torque converter, throttle position sensor, pre-bent steel cooler lines, SFI-approved flex plate, SST’s own heavy duty formed steel and powder coated crossmember and rubber isolator mount, speedometer cable, the complete wiring harness, inspection cover, mounting hardware, and a high strength, computer-balanced driveshaft with sealed u-joints and slip yoke.

As mentioned, the A41 is electronically shifted, and can be ordered with one of two module controllers: the Simple Shift is SST’s “manual controller” that requires no use of a laptop, yet allows for full adjustment of the shift points and firmness, and the torque converter lockup. Programmed with a built-in “Dual Mode” switch and pre-programmed TransView software, it comes with built in diagnostics and is the most “hands on” of the two. The Programmable Controller is a separate module pre-programmed with Transview Software and also permits for a “Dual Mode” switch, but intelligently adjusts the shift points to your driving style. “Dual Mode” allows drivers to switch between the smooth, effortless shifts in Cruise Mode, and the firmer, aggressive shifts of Performance Mode.

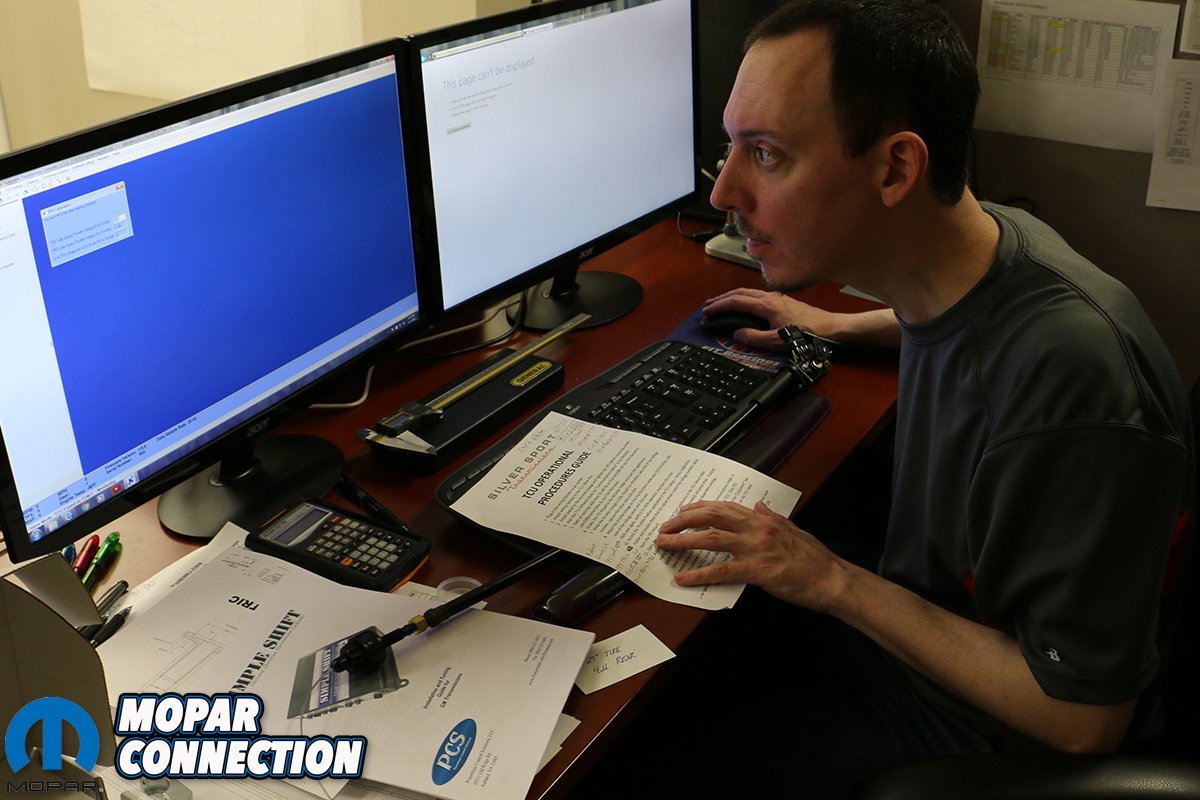

Above left: Prior to sending out any kit, SST’s engineers studiously pre-program every control unit with preset shift parameters. The TransView software is intelligent, meaning it will optimize and self-adjust as it gathers more data while you use it. Above center and right: Prior to installing the A41 itself, we started routing the wire loom, hung the module and began routing our wiring. Joy!

Above: After several measurements, we were sure we were in the right spot and drilled into the floorboards to route our OEM-style plug and loom to the overdrive. Of course, this was a personal choice, and most applications will not require the use of a hole saw.

Above left: Here you can see how we routed our loom through the floor and through an elongated hole already in the subframe. Above center: With our wiring in place, we raised the A41 into position. Above right: It was easier to begin plugging in the wiring with the transmission separate from the engine.

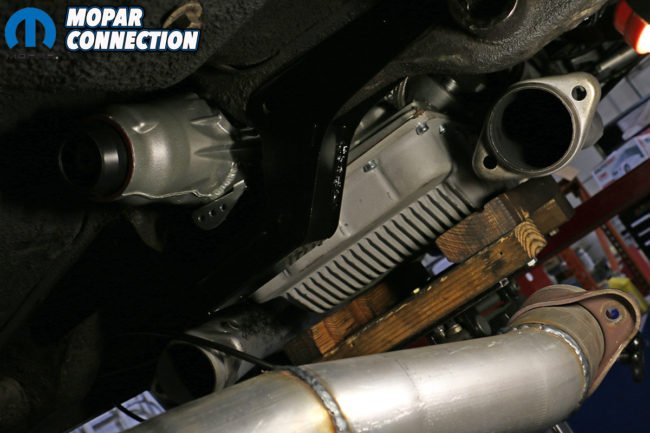

Yet most impressively, the kit requires zero cutting to the car, only some slight body contouring to clearance the large shift solenoid on the passenger side transmission tunnel. “We ensure that you can still use your factory center console and shifter position,” Jack Silver assured. A paper template is provided to clearly mark where (and how deep) the indentation needs to be made. The A41 surprisingly is more narrow than the 727, but at a slight offset, making the large, deep cast aluminum pan hug the passenger side header. Likewise, the the right hand side also receives both cooler lines, which we plumbed directly into our Be Cool radiator and saved SST the external ATF cooler and lines, as well as the large ECM harness plug.

The harness proved to be a little tricky, as the OEM-style plug is over an 1-inch in diameter. We opted to mount the ECM close to our FAST ECU and ignition box, meaning the loom needed to reach back below the passenger and all the way to the EFI throttle body to reach the throttle positioning sensor. With the aid of a hole saw and some large rubber grommets, we ran the plug through the inner rocker, behind the cross brace (that runs to the forward sub-frame), and up and over the header to the transmission. The 4-foot shifter cable was less troublesome, running from our TCI Outlaw, properly fitted with a 4-speed, forward-pattern shift gate, to the A41 electronic shifting module. To actuate the A41’s “Dual Mode” we opted for one of TCI’s Outlaw shifter accessory switches (although SST’s supplied switch illuminates when activated, making it easier to remember which setting you’re in).

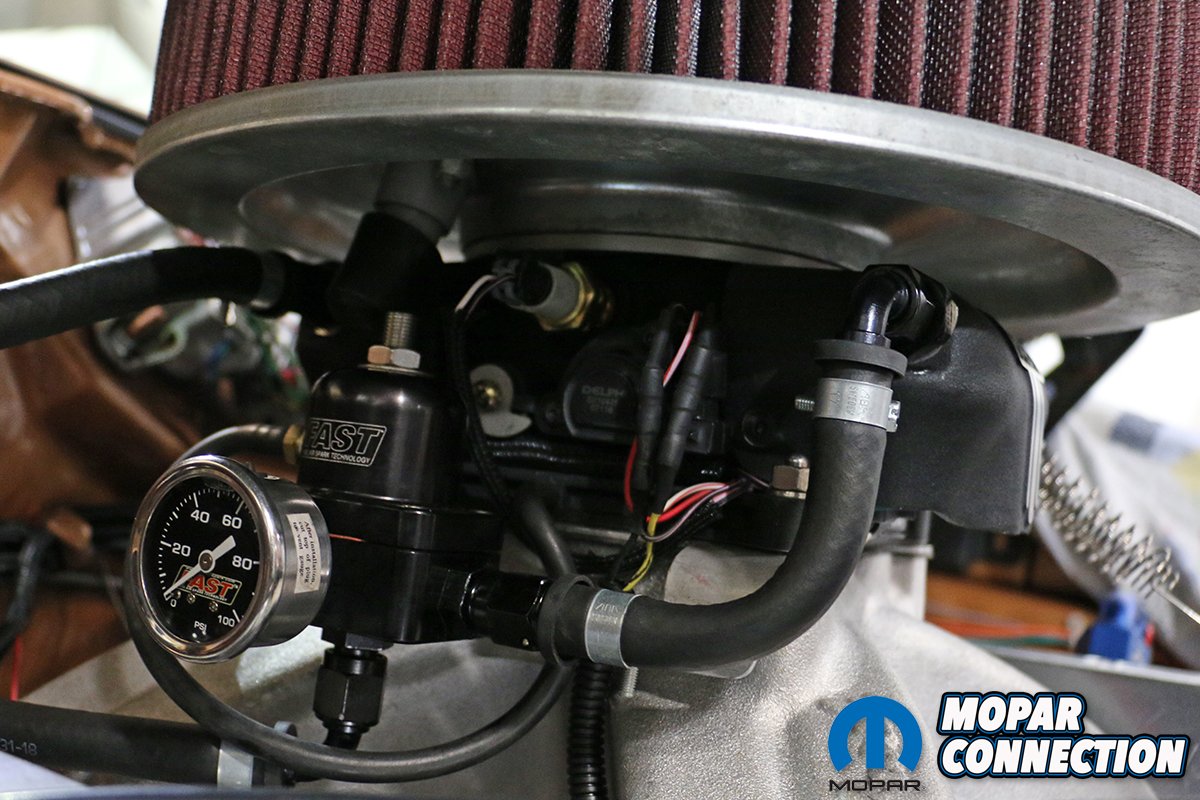

Above: One final bit of imperative wiring is splicing the transmission control module’s throttle positioning sensor bung with the TPS on our FAST EZ-EFI 2.0 throttle body. If you’re running a carburetor, SST will supply you with the necessary linkage and sensor to set this up.

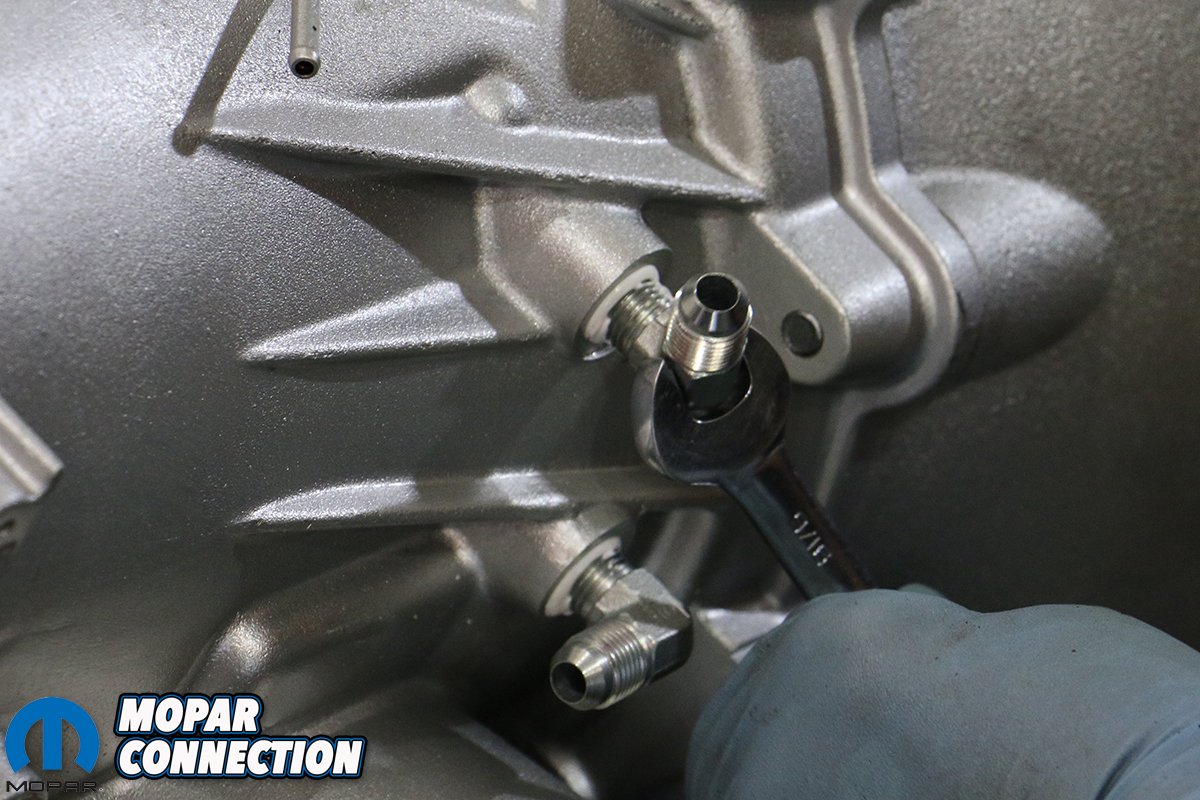

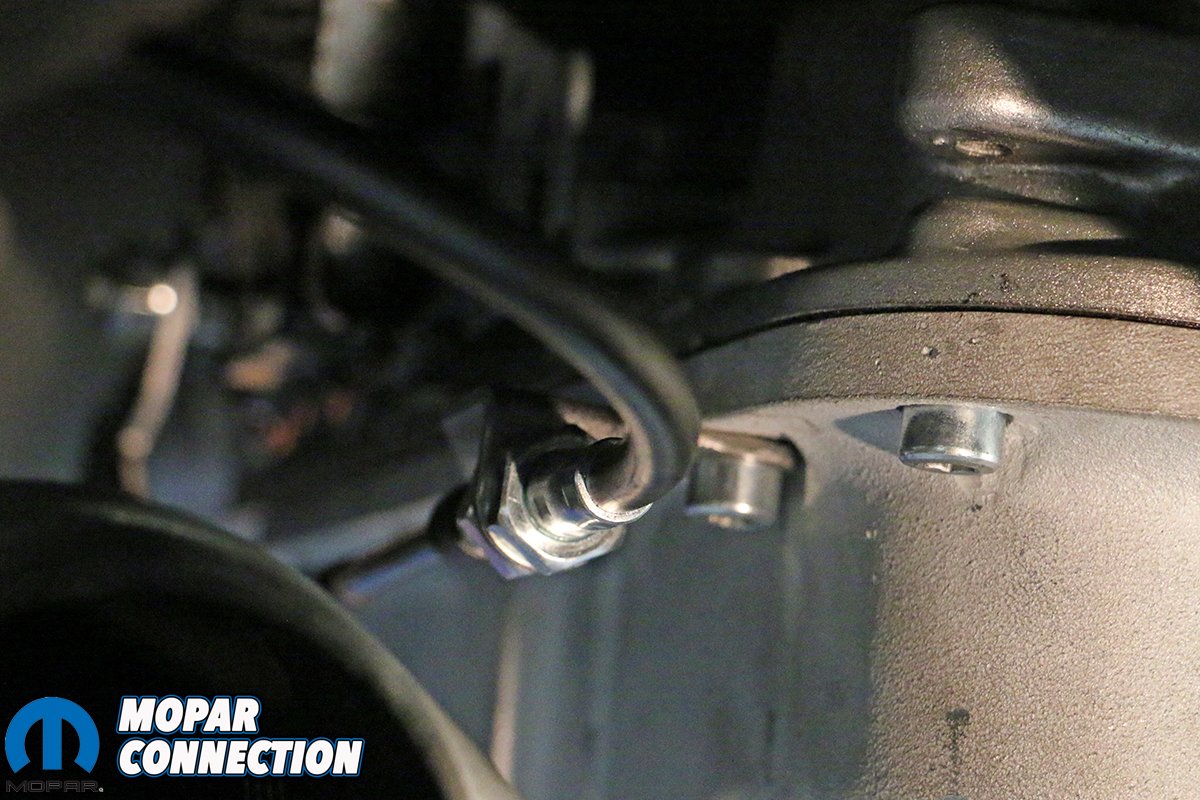

Above left: Because of the tightness of the cooler lines, it’s best to install the supplied 90-degree fittings prior to installing the overdrive. Above right: Likewise, it was easier to attach the cooler lines with the transmission not yet mated to the engine.

Above left and center: It was easier to attach the cross member/transmission mount prior to installing the overdrive itself, and the fabricated cross member. (Note how deep the new A41 cast aluminum pan is!) Above right: Once bolted to the back of the engine, with the torque converter bolted (with thread locker) to the flywheel, and starter in place, we inserted the new driveshaft.

Once installed, wired and plumbed, the SST-fabricated cross member was fastened down and the new driveshaft inserted. With SST’s Dick McCord sitting shotgun, we took Brazen out for its maiden voyage on a drizzly, overcast afternoon. In Cruise Mode, the A41 smoothly glided through the gears, dropping the tachometer’s needle a little lower with each shift. At 60 mph we danced just below 2,000 rpm, the big wedge thrumming effortlessly. On the freeway, pushing 75 mph spun the tach up to 2,500 rpm. While fuel efficiency was never of calculable interest before (primarily because it was so terrible), we’re now seeing over 10 miles per gallon with extended highway use. Yet, it’s the drop in rpm and the (prolonged) potential wear on the engine that excites us the most.

In as many months, our two latest additions: electronic fuel injection and an electronically-shifted overdrive transmission have radically changed our project car’s driveability, road manners and longevity. It fires up and cruises like a new truck, and it’s more than happy to obliterate the tires at the race track, as we proved during a short test and tune session at our local 1/8-mile track. While we didn’t go to set any records or even put some daylight beneath the front wheels, we were happy to drive all the way out to shake down Brazen, experience “Performance Mode” as it snapped through the gears, and then switch back over and drive the 50 minutes back home like a brand-new Hellcat. We’ll have plenty more race data to come soon enough!

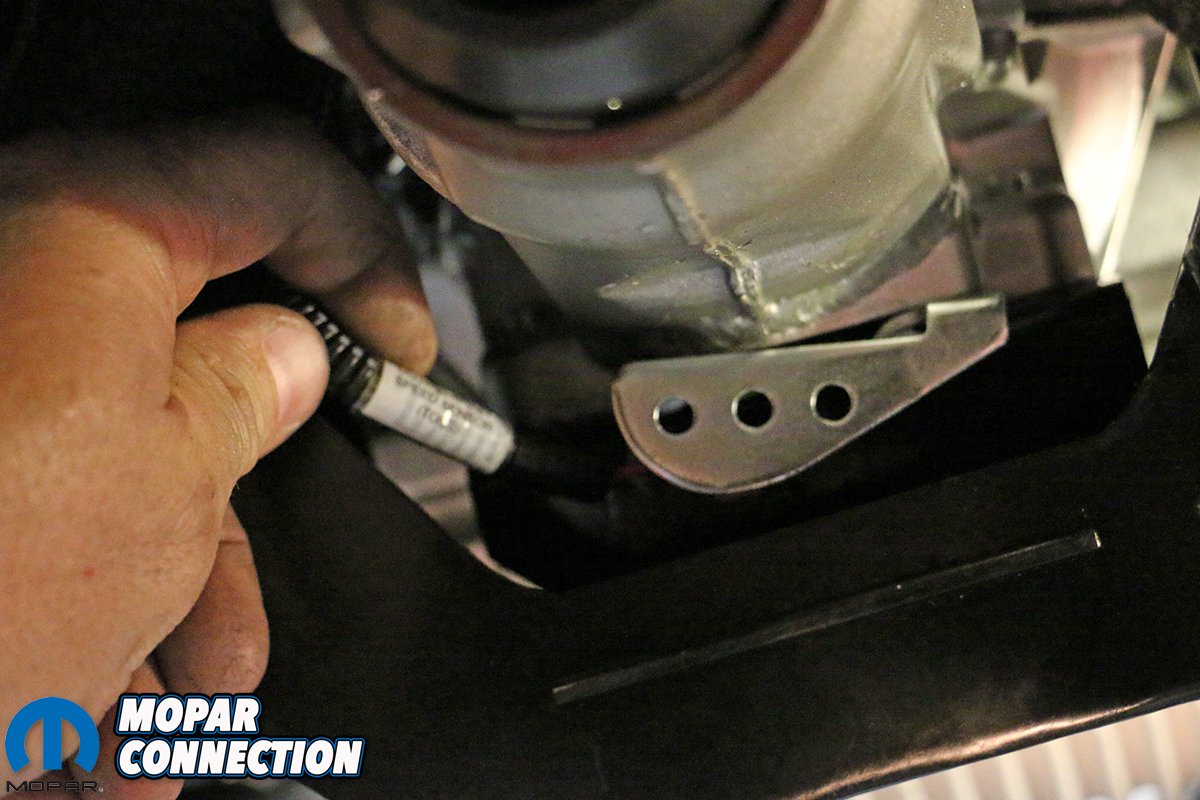

Above: We took the extra measure by removing the cable from the core and lubing the speedometer cable prior to installing it in the tail cone, located just inside of the cross member.

Above left: The final step to our installation was the modifying of a TCI Outlaw shifter from a 3- to a 4-speed. TCI sells the shift gate separately and is quickly swapped. Above center: We also installed a TCI Outlaw accessory switch to use as our toggle between our A41’s “Dual Mode” shift programs. Above right: The shifter linkage went in smoothly, snaking over and behind the overdrive into a bracket that needed some customization to fit the thick-cast aluminum pan.

Above: We didn’t come to set any track records this day, but to shake out the bugs that go unnoticed until a car is pushed to its limits. We have been driving Brazen regularly between the A41 install and our first track day and even drove the 45-50 minutes to the track, raced for a couple hours and drove back home that evening, much to the amazement of onlookers.

I see where the A41 Perfect fit tm Kit can fit on to a ford fe block can I get more information on this please

Sure, call Silver Sport Transmissions at 865-609-8187